STEEL BEAMS WITH WEB OPENINGS

The responsibility of a Structural Engineer lies in not merely designing the structure based on safety and serviceability considerations but he also has to consider the functional requirements based on the use to which the structure is intended. While designing a power plant structure or a multi-storeyed building, the traditional structural steel framing consists of beams and girders with solid webs. These hinder the provision of pipelines and air conditioning ducts required for satisfactory functioning for which the structure is put up. Very often, the service engineer who is on the scene long after the structural erection has been completed is required to fix air conditioning ducts in place. The re-routing of services (or increasing the floor height at the design stage for accommodating them) leads to additional cost and is generally unacceptable. The provision of beams with web openings has become an acceptable engineering practice, and eliminates the probability of a service engineer cutting holes subsequently in inappropriate locations. Beams with web openings can be competitive in such cases, even though other alternatives to solid web beams such as stub girders, trusses etc are available. This form of construction maintains a smaller construction depth with placement of services within the girder depth, at the most appropriate locations. The introduction of an opening in the web of the beam alters the stress distribution within the member and also influences its collapse behaviour. Thus, the efficient design of beams and plate girder sections with web openings has become one of the important considerations in modern structures. In this chapter, methods to evaluate the ultimate shear capacity of the beams and fabricated girders with circular or rectangular web openings are discussed. The methodology is based on the Von Mises yield criterion.

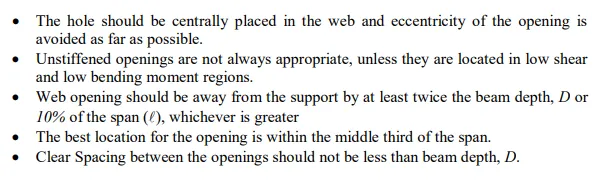

GUIDELINES FOR WEB OPENINGS AND STIFFENERS

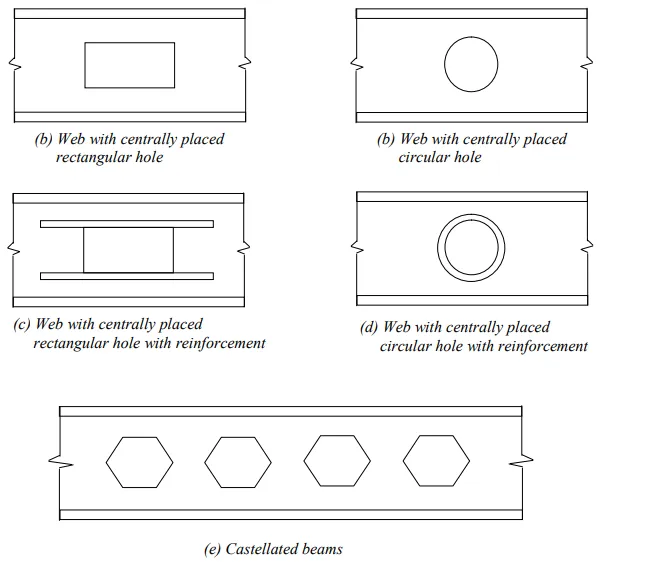

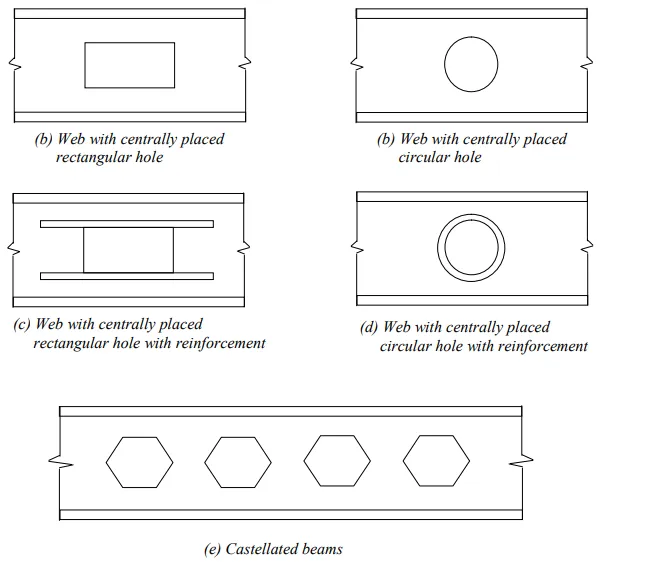

The shape of the web openings will depend upon the designer's choice and the purpose of the opening. There are no hard and fast rules to dictate the shapes of the openings. But, for designer's convenience, openings of regular shapes (such as circular or rectangular) are usually chosen. Introduction of openings in the web decreases stiffness of the beams resulting in larger deflections than the corresponding beams with solid webs. The strength of the beams with openings may be governed by the plastic deformations that occur due to both moment and shear at the openings.

The strength realised will depend on the interaction between the moment and shear. The moment capacity of the perforated beam will be reduced at the opening because of the reduction in the contribution of web to the moment capacity. This is not very significant, as usually the contribution of the web to the moment capacity is ver

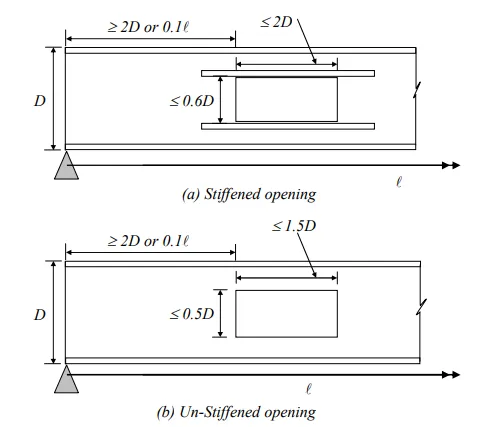

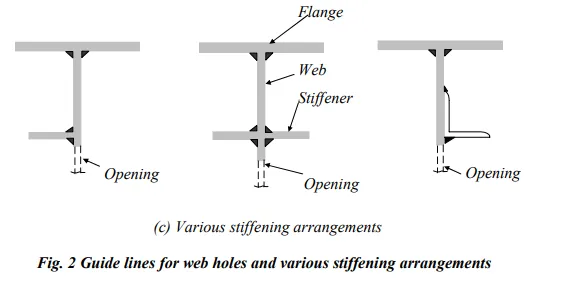

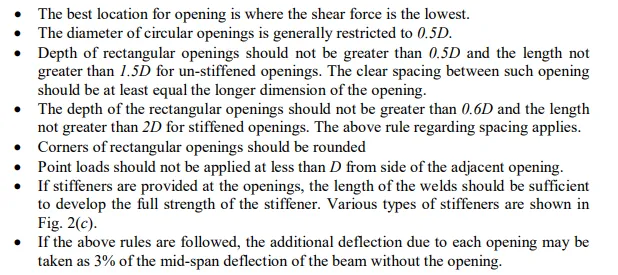

y small. However, the reduction in shear capacity at the opening can be significant. Therefore the ultimate capacity under the action of moment and shear at the cross section where there is an opening will be less compared to that at the a normal cross section without opening. i.e. some strength is lost. To restore the strength lost, reinforcement along the periphery of the openings could be provided. As a general rule, we should avoid having openings in locations of high shear, nor should they be closely spaced. Common types of web openings with and without reinforcement are shown in Fig. 1. The following general design guidelines may be useful [Fig. 2 (a)].

Fig.1 Common types of web openings