Fundamentals of the Strength of Materials

The strength of materials

concerns the data related to materials to determine their capability to resist

the applied loads and assist in production of strong components with a durable

life. Failure analysis is conducted to determine the causes of failure and

carry out improvements in the products.

What Is Strength Of Materials?

Strength of Materials is an

engineering discipline within Material Science that is related to the

capability of solid bodies to withstand different types of forces, including

axial loading, thermal loadings, and torsional loading. Analysis is carried out

to determine the stress, strains, and dislocations created by the applied loads

until failure, and such analysis explains the mechanical performance of the

components. The real operating conditions, failure analysis, and resistance to

deformation and cracking that are evaluated are influenced by not only the

strength of the material, but also by its shape.

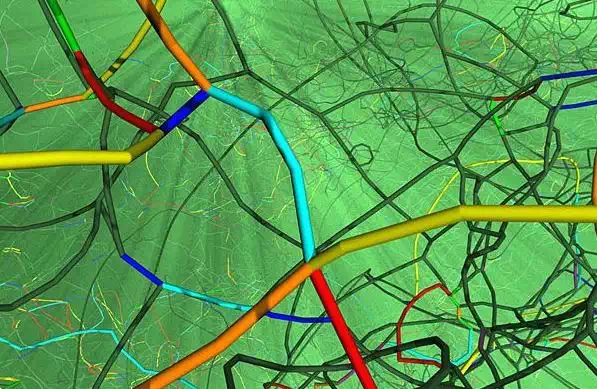

The Microstructure Of Materials

The strength of a material is

determined by its microstructure so that it can be classified as metallic,

ceramic, polymeric, and composite. The microstructure has a strong influence on

the physical characteristics of the material like strength, hardness, corrosion

and wear resistance, and ductility. When selecting a material for an industrial

application, all these physical properties of the material are taken into

consideration. The microstructure of the materials can be changed considerably

by the application of several strengthening processes such as hardening and

grain boundary strengthening. The most important useful field of the science of

the strength of materials is the dynamic loading that provides an accurate analysis

of the actual performance of the material during use for the designed purpose.

Strengthening Of Materials

The mechanical properties,

like yield strength, tensile strength, toughness, and ductility can be improved

by the application of appropriate techniques, due to which a wide range of

materials are available with mechanical properties that are in accordance with

the actual requirement. Properties of steel can be improved by the addition of

carbon, yield strength of materials is increased by the process of work

hardening, and the technique of solution strengthening improves the properties

of brass. Other strengthening processes normally employed are precipitation

hardening and grain boundary strengthening. Strengthening of materials are

processes that make the materials stronger by restricting macroscopic

deformation in materials that causes plastic deformation.

Applications Of Strengthening

Techniques

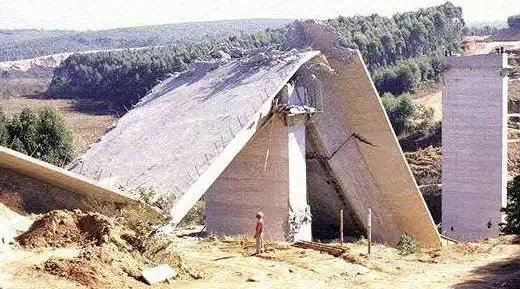

Techniques for the

strengthening of materials are essentially required in numerous fields,

including construction, bridges, steel frames, and roof materials. Strong

frames are required for the bridges to withstand high compressive and tensile

stresses, and the steel structures used in buildings should be robust to bear

the stresses and prevent bending due to the building weight. Similarly,

materials used for the roofs should be firm to ensure prevention of roof caving

due to excessive weight.

Failure Analysis

Failure analysis is an

important function of all engineering disciplines since these analyses assist

in determining the causes of failure and methods to prevent failure in future

applications. Failure may occur during the manufacture of the product or during

the use, and all the related data will contribute to the removal of the defect

in future production of the component. Failed components are examined through

the utilization of numerous techniques and test equipment, including microscopy

and spectroscopy. Analytical and computer modelingmethods

are used to envisage the life of the components, and the conclusions are

verified by empirical data.