Tips In Proportioning The Geometry And Reinforcement Of Conventional Slabs

Slab design may not be that Ďchallengingí to some compared to designing walls and columns and the parts of the lateral force resisting systems (LFRS). Granting that such is the case, none can discount the fact that slab design remains one of the major items that need to be done nonetheless. In fact, slabs have the lionís share in terms of the structural cost of a building.

To satisfy both the client (cost-wise) and good engineering judgement, the engineer should have good proportioning skills of the slab thickness and the reinforcement.

By the way, itís one thing to design it using software but itís another thing to proportion them such that it has just the right thickness and just the right amount of reinforcement. Remember, we should have a picture of the client with a smile that extends to both ears and his two thumbs up!

So how do you do this? Here are some practical guidelines and general considerations:

Limit maximum bar diameter in the slab. It is quite common to see 20-25mm diameter bars at supports especially on drop panels. 20mm bar diameters (25mm on extreme cases) is acceptable on a FEW locations at midspan of column and middle strips. However, if youíre seeing extra 20s and 25s on typical spans, then something is wrong. You need to thicken the slab.

Where possible, aim to have only minimum reinforcement on typical spans. Minimum meaning the typical reo provided.

Obey the reo rates. Reo (reinforcement) rate is the total weight of reinforcement within a specified volume of concrete, expressed in kilograms per cubic meter of concrete or kgs/cu.m. Under typical loading, the reo rate for slabs is usually 120 kgs/cu.m. If your rate is less than or equal to that, then youíre hitting your target right. This rate also shoots up depending on the occupancy. We may have MEP rooms and water tank somewhere, etc. Note that there are no established standards (as far as I know) on reo rates. It varies depending on the owner or developer on what they want to achieve.

Most of the time, deflection governs the design over strength requirements. The two checks mentioned are on different limit states by the way. Deflection is a serviceability check and strength obviously is ultimate. So if youíre checking the slab reinforcement, you can actually tell that the provided reinforcement is for deflection. How? Experience will. Design a slab and take note of your observations and come back and re-read this post.

Larger deflections are more common in the end spans. Compared with the internal span of a continuous strip with a typical grid, the sagging moment (positive bending moment at midspan) at the end spans is usually 20% greater than the sagging moment at the internal span. So greater deflections and flexural requirements are expected at end spans.

With reference to item 5 above, it is also normal that the end spans have a thicker slab than internal spans.

To such problematic areas where the reo layout is already a mess (when additional layers are required) what is usually done is to provide a higher mesh. Say you need to provide T16-200 both ways, top and bottom instead of T12-200.

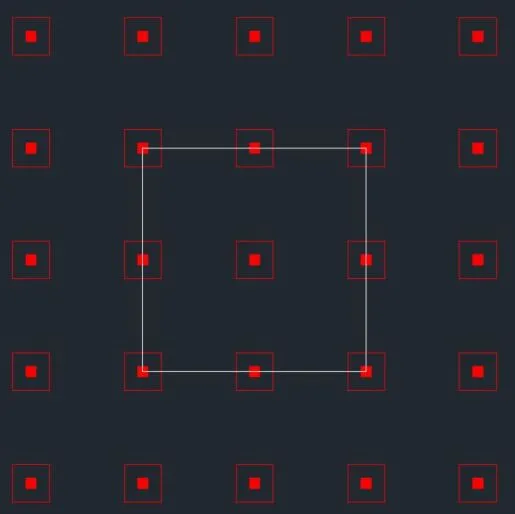

When you need to provide a thickening internally, be sure to extend it to the extremities of the affected drop panels in the perimeter as shown below. The reason is to provide adequate space for the flexural reinforcementís development length. This is to make sure that the bending moment can safely crossover from the support provided by the columns to the surrounding slab.

Donít thicken it this way. Yours truly.

Donít thicken it this way. Yours truly.

Thatís more like it. Still by yours truly.

Thatís more like it. Still by yours truly.