A Moment Of Columns Without Moment

A column that does not directly take bending moments from the slab.

Let that sink in for a while. As you come to realize it, you might have been aching to say “what the –“ (or maybe you just did.) That’s exactly the same reaction I had when I first encountered it. For us guys who are used to designing and detailing in accordance to seismic provisions, it just doesn’t seem to make any sense. That’s because we try to make things seamless where bending moments are unrestricted to flow to and fro the intricate structural assemblage. That is until plastic hinges are formed away from the joints. What we’re trying to achieve in doing as such is to protect the joint which consequently prevents brittle or “crispy” failure.

Fact is, this type of column construction (moment-less transfer, not deliberately building brittle frames!) is indeed a reality and is prevalent in countries where there is zero to moderate seismicity like Australia.

Does that even work? Yes of course it does. Albeit it requires a considerable amount of forethought and intimate understanding of how your structural system works. What rocks when designing such columns is you can almost always get a realistic design with gravity loads by doing even just a simple load rundown plus a minimum bending moment. There’s not much complications even when you have varying loads per floor that produces varying bending moments along the length of the column.

The consequence however of columns that do not take bending moment is they can only support gravity loads; and lateral loads resistance by such columns goes out the window. Unlike moment frames that provide redundancy when transmitting lateral loads (to a certain degree at least) pin-end columns cannot add significant lateral stiffness to the building.

What does this imply? The structure needs a clear-cut lateral load path towards the lateral force resisting system and a definite LFRS that will transmit lateral loads down to the foundation. The load path should be pretty much premeditated with supposed to be minimal amount of error. You cannot say later “oops, well frame action will take care of that.” It may, but with this type of construction it may not.

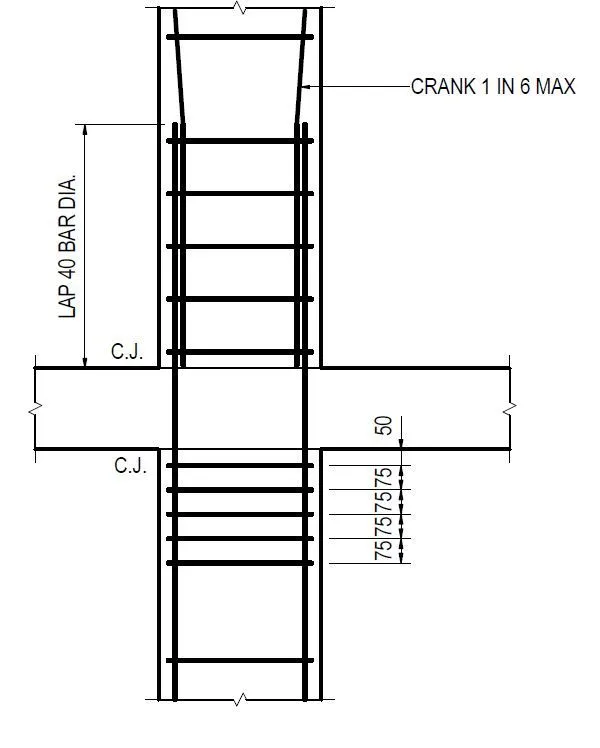

How is this “pinned ends” condition actualized in construction? By locating reinforcement laps near the joints. As such, plastic hinges are induced to form at the joints, consistent with the analysis and design intent. Of course a perfectly pinned column isn’t going to be achieved. There will still be a certain degree of fixity, but I would presume it is only minimum which is consistent with the design unless actual tests are conducted that will prove otherwise.

Cropped

Cropped

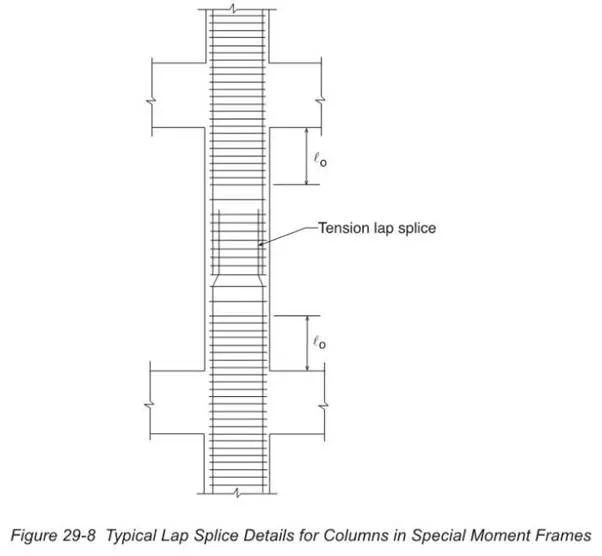

Considering seismic detailing however, lap locations are considered weak points in the structure hence they are required to be moved towards the center or midheight of the column where stress reversals are smaller compared near the joints. Links confining lap splices also require a code-prescribed minimum spacing (clause 21.6.3.2 of ACI 318-08).

Taken from PCA Notes on ACI 318-08

Taken from PCA Notes on ACI 318-08

What’s in it for us? For one, to inform us that something as such exists. Next is to give us a caveat that while this would free our columns from large amounts of bending moments, a thorough examination of what happens with the bending moments and shear forces the columns are supposed to support and where it goes is mandatory.