Tips In Checking Service Crackwidths Using Bs 8110-2:1985

When acted upon by service loads, a structural element especially those that are predominantly resisting bending will experience cracking on the surface in tension when itís modulus of rupture is exceeded.

If youíre using BS and you have a project in the middle east, chances are youíre going to check crackwidths.

Now depending on the exposure youíd get different allowable crackwidth limits. When a structure is a typical water-retaining structure, youíre going to be limited to 0.20mm crack width. The same limit applies for that part of foundation whose soffit is on soil Ė the reason perhaps is because of the cracks that expose the reinforcement to corrosion. Then thereís a more stringent limit of 0.10mm for areas susceptible to sulfate attacks (please ask Angus MacGyver to explain wazza sulfate attack). And thereís the requirement for the typical, less environment-exposed structural members such as internal suspended slabs and beams which should not exceed 0.30mm crack width. By experience though, once strength requirements are satisfied you were also able to satisfy the 0.30mm limitation. Not convinced? Go figure!

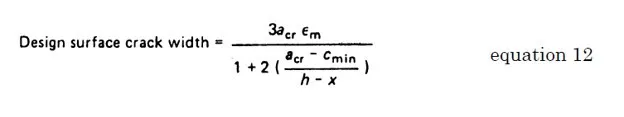

But whatever the heck the limit is, BS tells us that there is only one equation for crackwidth calculation.

Cropped from BS 8110-2:1985

Cropped from BS 8110-2:1985

But before we go to that part letís first settle which load combination will be used. Crackwidth check is a serviceability check which should now be obvious that we will use service loads. Long story short, we should only use permanent loads such as dead and live loads. Wind and seismic loads are transient loads and are by no means permanent unless itís already Apocalypse A.D.

Limits, check. Load combination, check. Letís now head for covers.

Actual cover is, well, the actual cover for the reinforcing steel. I am not power tripping with words by the way. You need to be able to read through some vocabs because it comes with different names such as steel cover and concrete cover and whatnot on different programs and spreadsheets .

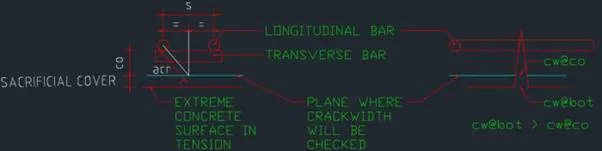

And there is the sacrificial cover or that cover where crackwidth will be checked. Now this needs some illustration to be fully explained.

by yours truly

by yours truly

While we have actual concrete cover it does not necessarily mean that we need to satisfy crackwidth limitations at the extreme fiber in tension. The extreme concrete fiber in tension can crack as much as we allow it to, but at a distance of a couple of inches or so below the lowermost tensile reinforcement (we use 40mm; others use 30mm and even 25mm) the crackwidth should be controlled by the allowable limits. (In as much as Iíd like to let you know where this came from, I canít. Not that I donít want to but because I havenít yet dug deep into the matter to know which code specified this methodology. )The distance of the said controlled edge to the extreme fiber in tension is the sacrificial cover.

If this is still confusing just remember our rule of thumb: the farther the distance of the tensile reinforcement from the edge, the larger the crack.

Now if youíre already at the edge of your nerves ready to implode in trying to comprehend concrete cover terminologies that vary from one spreadsheet to another software, you can just try to remember this instead:

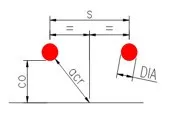

cropped from a spreadsheet

cropped from a spreadsheet

Dia is the bar diameter, s being the spacing, co as the cover from the longitudinal reinforcement to the surface where crackwidth will be checked, and acr which can be established by the theorem of our good old friend Pythagoras. Get it right and you can be sure to get the right geometry for acr and the right crackwidth.

Now thatís much easier to remember (right??) All you have to do is to exert your finger muscle in a calculator to verify your inputs and you donít even have to decode which cover means what which is why I wrote this post in the first place.

Now letís wrap this up by taking a look at the required inputs that have something to do with crackwidth computation:

Ms Ė the service moment (be reminded that this is a serviceability requirement). But what if youíre just taking a unit width? Better make sure that your Ms is in kiloNewton meters per meter (kN-m/m)

d Ė effective depth from the extreme compression fiber to the centroid of reinforcement

b Ė width b. If itís a beam or a narrow pad footing that youíre checking, b is the total width; if itís just a portion of the a slab or footing or wall or whatever, itís gotta be a meter

As Ė is the total flexural requirement. If the reinforcement is a function of the bar diameter and spacing, it would be per unit width or in square mm per meter (mm^2/m)

S Ė bar spacing. It is the spacing of the extreme longitudinal bars parallel to bending. Now you might get confused because of the manner you provided your As. But donít be. Just remember the above diagram for As. Youíre checking the crack at the concrete section in tension using the arrangement of the extreme tensile steel. So whatever bars you provided above it is irrelevant.

Dia Ė bar diameter for As. Again this has something to do with the bar arrangement of the extreme tensile steel for the computation of acr. Now say you have extra bars whose diameter is different with your provided mesh, what we do is we use the smaller diameter so that acr will be larger and the resulting crackwidth is also conservatively larger.

And finally the cover co where even if itís hard to distinguish because of its many aliases, it can be verified by ensuring that acr is correct.

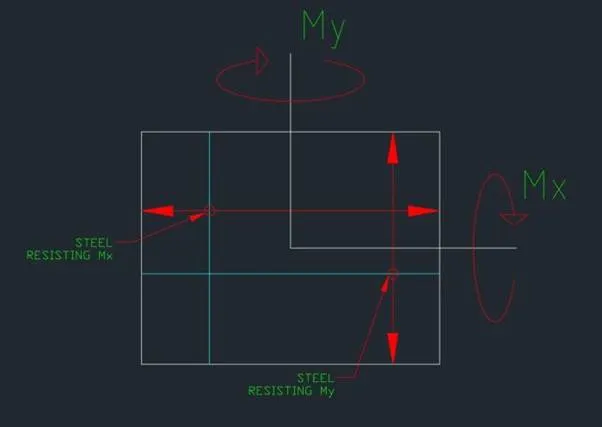

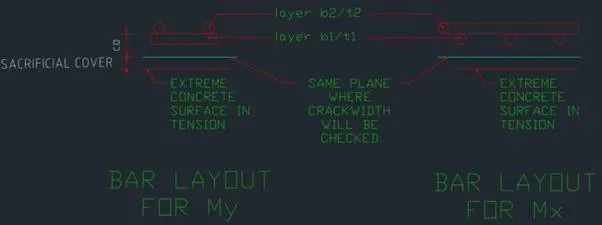

One last tip. Suppose youíre using the next layer of reinforcement to check the crackwidth for both direction (either t2 or b2; smaller capacity and thus more conservative. And donít forget that you need to check crackwidths in the two orthogonal directions) donít forget to include the largest bar diameter of the bar below in the computation of acr. That is because we consider the same plane were crackwidth will be checked for the two orthogonal directions. The illustration below should explain it in detail.

Drawn by yours truly

Drawn by yours truly

Ė including this one.

Ė including this one.