Cable Structures

Overview Historically, cables have been used as structural components in bridge structures. In this chapter, we first examine how the geometry of a cable is related to the loading that is applied to it. We treat concentrated loadings first and then incorporate distributed loadings leading up to a theory for continuously loaded inclined cables. We also analyze the effect of temperature on the cable geometry. Lastly, we develop an approximate formula for estimating the stiffness of a cable modeled as an equivalent straight member. This modeling strategy is used when analyzing cable-stayed structures.

Introduction

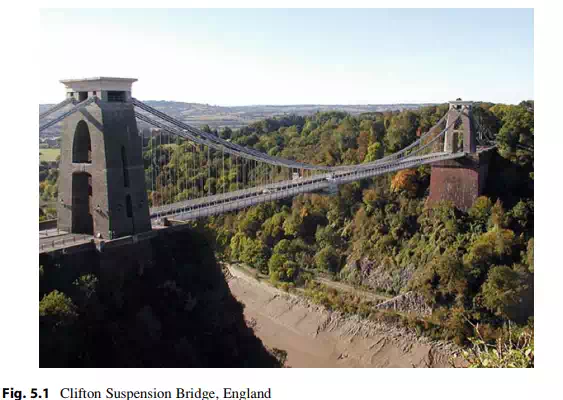

A cable is a flexible structural component that offers no resistance when compressed or bent into a curved shape. Technically, we say a cable has zero bending rigidity. It can support only tensile loading. The first cables were made by twisting vines to form a rope-like member. There are many examples of early cable suspension bridges dating back several thousand years. With the introduction of iron as a structural material, cables were fabricated by connecting wrought iron links. Figure 5.1 shows an example of an iron link suspension bridge, the Clifton Suspension bridge near Bristol England built in 1836–1864 and designed by Isambard Brunel.

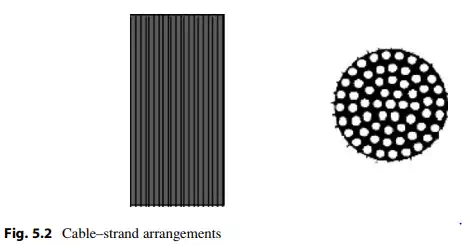

When high-strength steel wires became available, steel replaced wrought iron as the material of choice for cables. Modern cables are composed of multiple wires (up to 150 wires) clustered in a circular cross-section and arranged in a parallel pattern, as illustrated in Fig. 5.2. This arrangement is used for cable-stayed bridges and suspension bridges. The cable is normally coated with a protective substance such as grease and wrapped or inserted in a plastic sheathing.

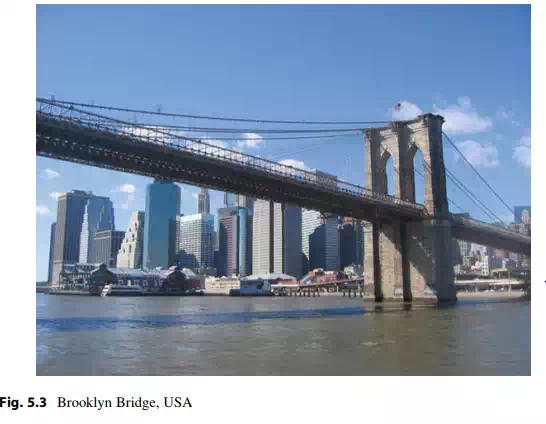

One of the most notable early applications of steel cables was the Brooklyn Bridge built in 1870–1883 and designed by John Roebling and Wilhelm Hildebrandt. John Roebling also invented and perfected the manufacture of steel

wire cable which was used for the bridge. At the time of completion, the total length of the Brooklyn Bridge was 50 % greater than any existing suspension bridge, an extraordinary advancement in bridge engineering (Fig. 5.3).

Cable-stayed structures employ cables fabricated from ultra high-strength steel to allow for the high level of tension required for stiffness. The cable-stayed bridge concept has emerged as the predominant choice for main spans up to about 1,000 m, replacing the conventional truss structural system. Figure 5.4 shows the Normandy Bridge, with a main span of 856 m. Built in 1995, it held the record for the largest main span until 1999, when it was exceeded by the Tatara bridge in Japan.

Cable nets are also used as the primary structural elements for long-span horizontal roof structures. Figure 5.5 shows a single-layer cable net structure with a double-curved saddle-shaped surface designed by Schlaich Bergermann and partners for a stadium in Kuwai.