A Complete Guide to a Lean Six Sigma tool:

Brief Introduction

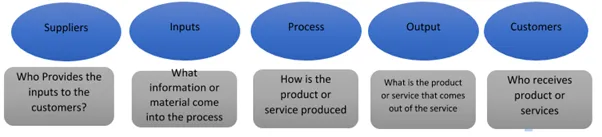

The above quote is very much applicable for SIPOC as well. The tool was introduced in late the 80’s under Total Quality Management (TQM); SIPOC is a primary element of the process. SIPOC seems to be a typical abbreviation of random letters, but this is written in a systematic way. This gives high-level process understanding to those who are unfamiliar with the process. SIPOC gives process knowledge to stakeholders and upper management; but, they should have an overview of all processes, SIPOC helps them with this.

If we need to improve or change a process, we must understand the process itself; which will be possible only if we know the suppliers, inputs, outputs, process steps, and customers.

This is called high-level Process Map or Bird’s eye view. This tool allows a team to view their process with respect to inputs, outputs, and suppliers. It provides the process scope while showing the process boundaries. Also, it helps in identifying the relationship among the supplier, inputs, and process; and gives visibility to the customers and their requirements.

SIPOC is not considered as process mapping or a flow chart, it is actually a traditional tool. It is used to overview the whole process with the suppliers, outputs, and inputs in one instant. It gives the insight of the suppliers, inputs, and outputs. While running the projects, a business must be aware of its suppliers and inputs; the potential causes that impact the processes and the outputs.

These potential causes are called as Xs/KPIVs. In the projects, if we know our Xs or KPIVs that could impact the process, we could identify the root causes. Once we are aware of the root cause, healing will be easy. Yet, SIPOC in a project is not considered as an important factor as it should be.

While running the process improvement project or the review process, SIPOC should be considered a key measure within the process. Since, the SIPOC consists of all the supplies, inputs. So that nothing gets ignored, which might be the reason for any causes.

In an ideal situation, we call this SIPOC. Whilst, working in a process the approach starts from customers to suppliers. What process steps should be taken to achieve the outputs? What are the inputs that would be desirable and those inputs’ suppliers?

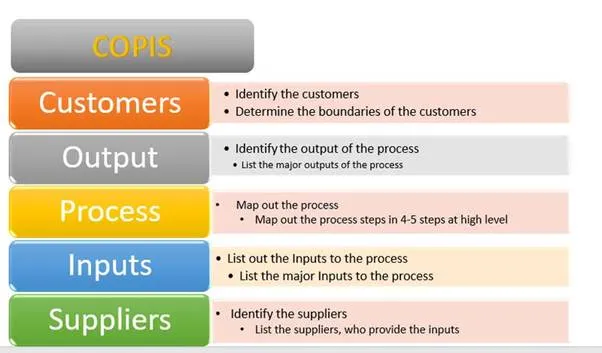

One can also say, “we work on COPIS”, which starts with customers. COPIS abbreviates to Customer, Output, Process, Inputs, and Supplier. Though, there is no difference between the SIPOC and COPIS; it largely depends upon the approach an organization prefers to use. A customer-centric organization prefers to implement COPIS. Then, the organization would understand the needs of the customer, from the customer’s point of view.

In COPIS, we see the process as per customer’s point of view; we work on the voice of the customers. We produce as per customer’s requirements, that is the output, and following the steps to produce the outputs with the relevant inputs and their suppliers. COPIS is used by the service industry. For example; in hotels, customers first place their need and then they get the service/food.

Service and manufacturing industries both use the SIPOC. However, it prepares by applying POCIS method. The first step is the process; then, the outputs that generate these steps and the aesthetic requirements of the customers, and their inputs and suppliers.

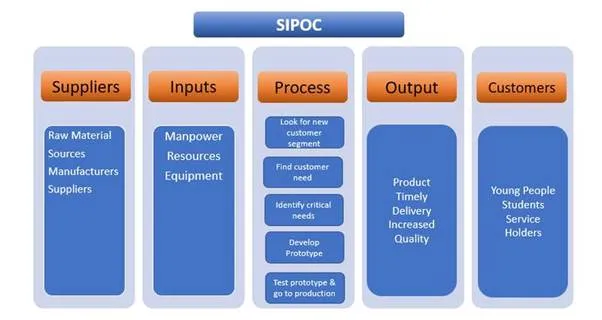

SIPOC Model

Suppliers: The inputs used in the process would be either be supplied by other processes or internally, or provided by another party or external customer. In the service industry, the process inputs could be obtained from other related processes. In the manufacturing industry, inputs like raw materials could be obtained from the same company or can be imported from other manufacturing industries. These are the suppliers for the inputs- the materials received for cooking from vegetable vendors, grocery shops, furniture, music systems, crockery from various vendors.

Inputs: The inputs consist of the Xs, these inputs impact the process. Since the processing is as the inputs we receive. If our outputs do not meet the customer’s requirements, we either have an issue with the inputs or the processing steps; there might be a chance that the supplier is providing the correct inputs. Hence, inputs for the process play a vital role. In the hotel industry, we receive different inputs from various vendors; these inputs are used for a single process, which is customer service.

Process: SIPOC, a high-level process map, shows the whole process in 4-5 major process steps. It provides process steps as manual instruction, it gives the picture of the functioning of the process. Now, after receiving all the inputs, there will always be the first step to decide the process. Some restaurants/hotels believe in “self-service” and some in serving their customers. So, the first step to serving would be taking the order from the customer, then providing them as per their requirements. One must always keep in mind the customer’s expectation from the service/food.

Outputs: The whole business depends on the outputs, after investing time in inputs and processing. Outputs are the end-products or end-results which come after processing. If processing and inputs are not up to the mark, the output will fail.

Customers: Customers are those people, from whom we get the business, it can be both internal or external. Internal customers are the stakeholders, the process improvement projects run for them. And the external customers or the end customers, who use the services or the end product or who decides the end product fit to their expectations or not. In other words, in the process of providing the end result to the external customers, there are many internal handoffs. Some of them are for the internal customers. If these handoffs are not successful in terms of time and accuracy, then the end result gets affected.

How and When to Use the SIPOC?

The SIPOC Model is useful in many ways- Concept, Purpose, and Practice. Since all the problems are not the only process-related; there might be a chance of receiving incorrect inputs. It might be that the outputs are not satisfactory due to miscommunication or the inability of the customer to express his/her requirements. Some people, during the process improvement, either ignore or skip the SIPOC, since they do not know how useful SIPOC is. They would not understand where the actual problems persist; like a doctor treating a patient without knowing the actual problem of the patient.

As mentioned before, SIPOC gives an overview of the entire process and the subsequent steps. It has many benefits, it makes it easy to identify the process improvement projects before the work begins. It helps in the seamless progression of the projects that are not scoped properly due to undefined or incorrectly defined metrics. It also helps in clearing the below doubts-

It answers the most difficult questions of the process; i.e., where do we consider the process to be starting and ending? What are the major steps involved in the process?

It gives an introduction to the inputs we need for the process and the expected outputs of the process, which can be single or many.

Also, it provides information regarding the suppliers of the inputs. Hence, in process improvement, we get in-depth information to the point of the suppliers; so as to find the root causes of the issues or problems. The suppliers can either be internal or external, they could be improved or changed as per the situations.

As we discussed, the customers can be internal or external. With SIPOC, we know the end-customers and the stakeholders who are being impacted by any issues related to customer satisfaction, and who wants to do the projects.

There are 5 ways to use SIPOC:

1. Visualize, understand and communicate the high-level processes, SIPOC is used to view all the processes in the same light.

2. Identify the customers’ requirements.

3. Plan a process walk.

4. Manage the detailed process mappings, identify the useful measures.

5. It also helps to understand how suppliers, inputs and process steps are affecting the customers’ needs.

Steps to create a SIPOC

SIPOC should be designed with the POCIS concept. The first process is deciding the major process steps involved in the projects. Outputs of the process and then customers’ needs, then work on inputs that are required to implement the process and their suppliers. Establish the name of the process for which SIPOC needs to be made.

· Decide the starting and ending points of the process; these steps should start with a verb. There is a person called Bill Peterson, he has considered in his writing that they should be called policies. Since a company works on policies, which they tailor as per their customers' requirements, to a certain extent; I also agree that it could be considered as policies.

· List down all the process steps; then pick the major process steps, there should not be more than 5 steps. However, in exceptional cases, we can see 8 steps as well.

· List down the outputs generated after processing, it could be one or more. Once you know all your internal and external customers, you can make a list of outputs that will be provided to internal and external customers. It should be written in nouns.

· Define the receivers of the products or services, it can be internal or external customers.

· List down the inputs of the process, that should also be written in nouns.

· Name the suppliers the business receives the inputs from.

Need for SIPOC tool in process improvement

SIPOC is the major key to process improvement. It is used in the Define phase to see the overall process at once; so that everyone is aware of all the elements involved in the process. The problems usually occur in the process steps, there is a great chance of errors due to incorrect inputs and supplies. Also, SIPOC gives the actual customers’ demand and all the outputs, or we could call them KPOVs. Hence, while planning for the process improvement project, one must not ignore the major step; i.e., SIPOC. Most times, it is implemented casually, and its importance is overlooked.

Conclusion

So, we can see how much SIPOC helps in understanding the overall process; this gives insight into where the problems persist. While making the project charter in the Define phase, SIPOC must be given importance; since it indicates the possible problems in the whole process. These problems could arise from the supplier side, they could be input issues or might be process steps. On the basis of this, we can design an appropriate plan for improvement.