MAIM: THE MERSEYSIDE ACCIDENT INFORMATION MODEL

Generally speaking, the term accident is used to denote events resulting in undesired or unplanned physical injury or damage; an accident model is a conceptual scheme applied to the analysis of such events. (Some models may explicitly declare that “near accidents”—sometimes known as “near misses”—are covered by the model; however, the distinction is not important to this article.) Models of accidents can serve different purposes. First, they may provide a conceptual understanding of how accidents occur. Second, models may be used to record and store information on accidents. Third, they may provide a mechanism for investigating accidents. These three aims are not entirely distinct, but form a useful means of categorization.

This article describes MAIM, the Merseyside Accident Information Model, which is most naturally adapted to the second purpose—recording and storing accident information. Following an outline of the rationale for MAIM, some early studies evaluating the model are described. The article ends with recent progress with MAIM, including the use of “intelligent software” to collect and analyse information on injury accidents.

Early Accident Modelling

In Heinrich’s model (1931), the causal sequence leading to an accident was likened to a sequence of five falling dominoes, each of the first four being necessary before the final event could occur. In a precursor to MAIM, Manning (1971) concluded that “the basic requirements of an accidental injury are the presence of a host [a worker, for example] and an environmental object which contributes to the accident. The host or the object or both move in relation to each other.” Kjellén and Larsson (1981) developed their own model, which posited two levels: the accident sequence and the underlying, determining factors. In a later paper, Kjellén and Hovden (1993) described subsequent progress in the context of other literature and noted the need for “efficient use of existing information from routine accident and near accident reports by means of a powerful information retrieval system”. This has been achieved for MAIM.

Rationale for MAIM

There appears to be a substantial consensus that useful information on accidents should not merely concentrate on the immediate circumstances of the damage or injury, but should also include an understanding of the preceding chain of events and factors causing the accident sequence to occur. Some early classification systems failed to achieve this. Understanding objects, movements (of people or objects) and events were commonly mixed and successive events were not distinguished.

A simple example illustrates the problem. A worker slips on a patch of oil, falls and strikes his or her head on a machine and suffers a concussion. We can easily distinguish the (immediate) cause of the accident (slipping on oil) and the cause of the injury (hitting the head on the machine). Some classification systems, however, include the categories “falls of persons” and “striking against objects”. The accident could be allocated to either of these, although neither describes even the immediate cause of the accident (slipping on oil) or causal factors (such as how did the oil get on the floor). Essentially, the problem is that just one factor is considered in a multifactorial situation. An accident does not always consist of a single event; there may be many. These points formed the basis for the development of MAIM by Derek Manning, an occupational physician.

Description of MAIM

The centrepiece of the accident is the first unforeseen (undesired or unplanned) event involving the damaged equipment or injured person. This will not always be the first event in the accident process described as a preceding event. In the example above, the slip counts as the first unforeseen event of the accident. (Given the presence of oil patches on the floor, it is not unforeseen that someone will slip on one and fall, but the person walking does not foresee this.)

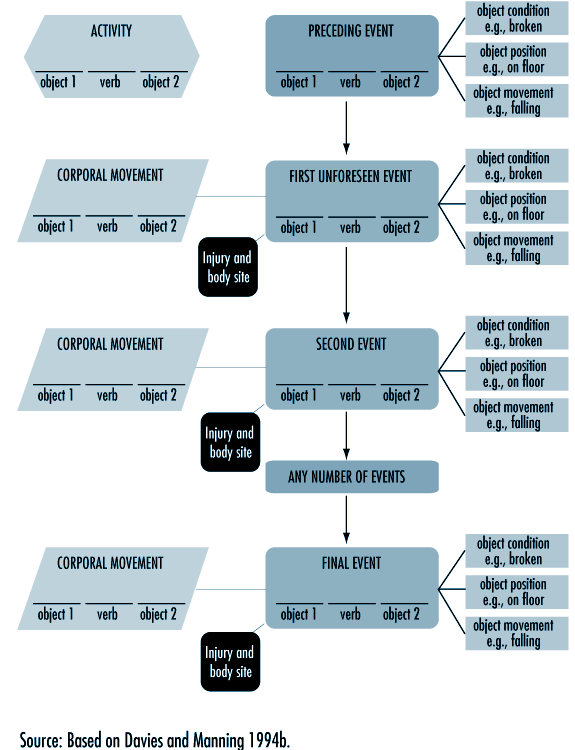

The MAIM Accident Model

The behaviour of the equipment or person is described by the general activity at the time and a more specific description of the type of corporal movement when the first event occurred. Objects involved are described, and for those related to events, characteristics of objects include position, movement and condition. On occasion, a second object which inter-relates with the first object may be involved (for example, striking a chisel with a hammer).

As noted above, there may be more than one event and the second event may also have an object (perhaps different) involved in it. Additionally, the equipment or person may make an additional corporal movement, such as throwing out a hand to prevent or break a fall. These can be included in the model. A third fourth or later event may occur before the sequence finally leads to an injury. The model can be expanded in all directions by recording factors related to each component. For example, branches from activities and corporal movements would record psychological factors, medications or physical limitations of a worker.

In general, separate events may be easily distinguished intuitively, but a stricter definition is useful: an event is an unexpected change, or lack of change, in the energy state of the situation. (The term energy includes both kinetic and potential energy.) The first event is always unexpected. Subsequent events may be expected, even inevitable, after the first event, but are always unexpected before the accident. An example of unexpected lack of change of energy is when a hammer being swung misses the nail at which it is aimed. The example of a worker who slips on a patch of oil, falls and hits his or her head provides an illustration. The first event is “foot slipped”—instead of remaining still, the foot acquires kinetic energy. The second event is “fell”, when further kinetic energy is acquired. This energy is absorbed by the collision of the worker’s head with the machine when the injury occurs and the sequence ends. This can be “plotted” onto the model as follows:

1. 1st event: foot slipped on oil.

2. 2nd event: person fell.

3. 3rd event: head struck against machine.

Experience with MAIM

An earlier version of the MAIM model was used in a study of all 2,428 reported accidents in 1973 in a gearbox manufacturing plant on the grounds of an automobile company. (See Shannon 1978 for further details.) The operations included cutting and grinding of gears, heat treatment and gearbox assembly. The cutting process produced sharp metal splinters and shavings, and oil was used as a coolant. Purpose-designed forms were used to collect information. Each accident was plotted independently onto the model by two people and discrepancies were resolved by discussion. For each accident, the components were given numerical codes, so the data could be stored on a computer and analyses performed. The following outlines some basic results and presents an examination made what was learned specifically from the use of the model.

The accident rate was substantially reduced (by nearly 40%), apparently as a result of the study being conducted. The researchers learned that because of the additional questioning that the study called for (and the consequent time involved) many employees “could not be bothered” to report minor injuries. Several items of evidence confirmed this:

1. The rate rose again in 1975 after the study ended.

2. The rate of lost-time injuries was unaffected.

3. Visits to the medical centre for non-industrial complaints were unaffected.

4. Accident rates on the rest of the grounds were unaffected.

Thus the reduced rate did indeed appear to be an artefact of reporting.

Another interesting finding was that there were 217 injuries (8%) for which the workers involved could not be certain how or when they occurred. This was discovered because workers were explicitly asked if they were sure of what happened. Typically, the injuries involved were cuts or splinters, relatively common given the nature of work at this plant.

Of the remaining accidents, nearly half (1,102) consisted of just one event. Two- and three-event accidents were successively less common, and 58 accidents involved four or more events. There was a marked increase in the proportion of accidents resulting in lost time with an increase in the number of events. One possible explanation is that there was an increase in kinetic energy with each event, so that with more events, there was more energy to dissipate when the worker and the object involved collided.

Further examination of differences between lost-time and non-lost-time accidents found very marked differences in the distributions for separate components of the model. For example, when the first event was “person slipped”, nearly a quarter of the accidents resulted in lost time; but for “body punctured by”, only 1% did so. For combinations of components, such differences were accentuated. For example, with respect to the final events and related objects, none of the 132 accidents in which the casualty was “punctured by” or “splintered” resulted in lost time, but when the final event was “strained/sprained” with “no object involved”, 40% of the injuries caused lost time.

These results contradicted the view that the severity of injury is largely a matter of luck and prevention of all types of accidents would lead to a reduction of serious injuries. This means that analysing all accidents and attempting to prevent the most common types would not necessarily have an effect on those causing serious injuries.

A sub-study was conducted to assess the usefulness of information in the model. Several potential uses of accident data were identified:

· to measure safety performance—the extent to which accidents in a plant, or area of a plant, continue to occur over time

· to identify causes

· to identify errors (in the broadest meaning of the term)

· to check on control—that is, to see whether safety measures taken to prevent some type(s) of accident are indeed effective

· to provide a basis of expertise, as knowledge of a wide range of accident situations and circumstances might help provide accident prevention advice.

Three safety officers (practitioners) rated the usefulness of the verbal descriptions and the plotted models for a series of accidents. Each rated at least 75 accidents on a scale from 0 (no useful information) to 5 (perfectly adequate for use). For the majority of accidents, the ratings were identical—that is, no information was lost in the transfer from the written descriptions to the model. Where there was a loss of information it was mostly just one point on the 0 to 5 scale—that is, only a small loss.

The information available, though, was rarely “perfectly adequate”. This was partly because the safety officers were used to conducting detailed on-the-spot investigations, something not done in this study because all reported accidents, both minor and more serious ones, were included. It should be remembered, however, that the information plotted onto the models was taken directly from written descriptions. Since relatively little information was lost, this suggested the possibility of excluding the intermediate step. The more widespread use of personal computers and availability of improved software make automated data collection possible—and allow checklists to be used by way of insuring that all relevant information is obtained. A program has been written for this purpose and has undergone some initial testing.

MAIM Intelligent Software

The MAIM model was used by Troup, Davies and Manning (1988) to investigate accidents causing back injuries. A database was created on an IBM PC by coding results from patient interviews conducted by an interviewer who was experienced with the MAIM model. The analysis of interviews to obtain the MAIM description was done by the interviewer and it was only at this stage that the data were entered into the database. While the method was quite satisfactory, there were potential problems in making the method generally accessible. In particular, two areas of expertise were required—interviewing skills and the familiarity with the analysis needed to form the MAIM description of the accident.

Software was developed by Davies and Manning (1994a) to conduct a patient interview and produce a database of accidents using the MAIM model. The purpose of the software was to provide two areas of expertise—the interview and the analysis to form the MAIM event structure. The MAIM software is, in effect, an intelligent “front end” to a database, and by 1991 it was sufficiently developed to be tested in a clinical environment. The MAIM software was designed to interact with the patient by means of “menus”—the patient selects options from lists which require only the use of cursor keys and the “Enter” key. The choice of an item from the list of options affected to some extent the path through the interview and also had the effect of recording information at the appropriate part of the MAIM description of the accident. This method of data collection eliminated the need for spelling and typing skills and also gave a repeatable and consistent interview.

The event structure of the MAIM model uses verbs and objects to form simple sentences. Verbs in events can be associated with different accident scenarios, and this property of the model forms the basis for the construction of a set of linked questions that form an interview. Questions are presented in such a way that at any stage only simple choices are needed, effectively breaking the complex account of the accident into a set of simple descriptions. Once an event verb has been identified, associated nouns can be found by locating the objects to form a sentence giving the full detail of the description of the particular event. It is clear that this strategy requires the use of an extensive dictionary of objects which can be searched quickly and efficiently.

The Home Accident Surveillance System (HASS) (Department of Trade and Industry 1987) monitors objects involved in accidents, and the list of objects used by HASS was used as the basis of an object dictionary for the MAIM software and was extended to include objects found in the workplace. Objects can be grouped into classes, and with this structure a hierarchical menu system can be defined—classes of objects form layers that correspond to menu lists. Thus a linked list of associated objects can be used to locate individual items. As an example, the object hammer could be found by selecting, in order:

1. tools,

2. hand tools and

3. hammer from three successive menu lists.

A given object could potentially be classified into several different groups—for example, a knife could be associated with kitchen items, tools or sharp objects. This observation was used to create redundant links in the object dictionary, allowing many different paths to find the required object. The object dictionary currently has a vocabulary of about 2,000 entries covering work and leisure environments. The MAIM interview also collects information on activities at the time of the accident, corporal movements, the location of the accident, contributory factors, injuries and disability. All of these elements can occur more than once in an accident, and this is reflected in the structure of the underlying relational database which was used to record the accident.

At the end of the interview, several sentences describing events in the accident will have been recorded and the patient is asked to put them in the correct order. In addition, the patient is asked to link injuries with the recorded events. A summary of the information collected is then presented on the screen of the computer for information.

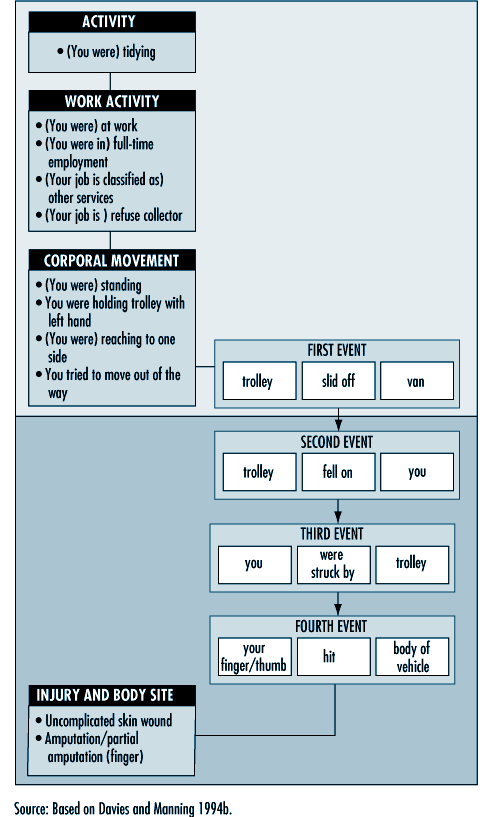

An example of an accident summary as seen by the patient. This accident has been superimposed on the MAIM diagram. Details relating to factors and the location of the accident have been omitted.

Accident summary as recorded by patient interview

The first unforeseen or unintended event (first event) involving the injured person is usually the first event in the accident sequence. For example, when a person slips and falls, the slip is normally the first event in the accident sequence. If, on the other hand, a person is injured by a machine because another person operates the machine before the victim is standing clear, the first event involving the victim is “trapped by machine” but the first event in the accident sequence is “other person operated machine prematurely”. In the MAIM software, the first event in the accident sequence is recorded and it may arise either from the first event involving the injured person or as a preceding event. Theoretically, this way of viewing matters may be unsatisfactory, but from the accident prevention point of view, it identifies the beginning of the accident sequence, which can then be targeted to prevent similar accidents in the future. (The term action of deviation is used by some authorities to describe the beginning of the accident sequence, but it is not yet clear if this is always synonymous with the first event in the accident.)

When the MAIM software was first used in a clinical setting it was clear that there were problems in correctly appraising some types of “underfoot” accidents. The MAIM model identifies the first unforeseen event as the starting point of the accident sequence. Consider two similar accidents, one in which a worker intentionally steps onto an object which then breaks, and a second accident in which a worker unintentionally steps onto an object which breaks. In the first accident stepping on the object is a body movement and the first unforeseen event is the object breaking. In the second accident stepping on the object is the first unforeseen event in the accident. The resolution of these two scenarios is to ask, “Did you accidentally step on something?” This demonstrates how important the correct design of the interview is in obtaining accurate data. The analysis of these two accidents allows recommendations on accident prevention as follows; the first accident could have been prevented by making the patient aware that the object would break. The second accident could have been prevented by making the patient aware that the object was an underfoot hazard. The MAIM software has been tested successfully in three clinical settings, including a 1-year project in the Accident and Emergency Department of the Royal Liverpool University Hospital. Patient interviews took between 5 and 15 minutes, and on average two patients were interviewed per hour. In all, 2,500 accidents were recorded. Work on publications based on these data is in progress.

PRINCIPLES OF PREVENTION: THE PUBLIC HEALTH APPROACH TO REDUCING INJURIES IN THE WORKPLACE

A public health approach to occupational injury prevention is based on the assumption that injury is a health problem, and as such can either be prevented or its consequences mitigated (Occupational Injury Prevention Panel 1992; Smith and Falk 1987; Waller 1985). When a worker falls from a scaffold, the tissue damage, internal haemorrhage, shock and death that follow are, by definition, a disease process—and also by definition a concern for public health professionals. Just as malaria is defined as a disease whose causal agent is a specific protozoan, injuries are a family of diseases caused by exposure to a particular form of energy (kinetic, electrical, thermal, radiation or chemical) (National Committee for Injury Prevention and Control 1989). Drowning, asphyxiation and poisoning are also considered injuries because they represent a relatively rapid departure from the body’s structural or functional norm, as does acute trauma.

As a health problem, injuries are the leading cause of premature death (i.e., before age 65) in most countries (Smith and Falk 1987; Baker et al. 1992; Smith and Barss 1991). In the United States, for example, injury is the third leading cause of death following cardiovascular disease and cancer, the leading cause of hospitalization under the age of 45, and an imposed economic burden of 158 billion dollars in direct and indirect costs in 1985 (Rice et al. 1989). One out of three nonfatal injuries and one out of six fatal injuries to working-aged persons in the United States occur on the job (Baker et al. 1992). Similar patterns apply in most of the developed world (Smith and Barss 1991). In middle- and low-income countries, a rapid and relatively unregulated pace of industrialization may result in a nearly global pandemic of occupational injuries.

Public Health Models for Injury Control

The traditional practice of workplace safety usually focuses on minimizing risks and losses within a single company. Public health practitioners engaged in occupational injury control are interested not only in individual worksites but also in improving the health status of populations in geographic areas that may be exposed to the hazards associated with multiple industries and occupations. Some events such as workplace fatalities may be rare at individual plants, but by studying all fatalities in a community, risk patterns and prevention policy may become evident.

Most models of public health practice are based on three elements:

(1)assessment,

(2)development of prevention strategies, and

(3)evaluation.

Public health practice is usually multidisciplinary and founded on the applied science of epidemiology. Epidemiology is the study of the distribution and determinants of diseases and injuries in a population. The three main applications of epidemiology are surveillance, aetiological research and evaluation.

Surveillance is “the ongoing and systematic collection, analysis and interpretation of health data in the process of describing and monitoring a health event. This information is used for planning, implementing and evaluating public health interventions and programs” (CDC 1988). Aetiological research tests hypotheses regarding the determinants of disease and injuries through the use of controlled, usually observational, studies. Evaluation in both applied social sciences and epidemiology is “a process that attempts to determine as systematically and objectively as possible the relevance, effectiveness and impact of activities in light of their objectives” (Last 1988). Epidemiological evaluation usually entails the use of controlled study designs to measure the effects of an intervention on the occurrence of health-related events in a population.

The basic model of public health practice is described by a cycle of epidemiological surveillance, research on causes, interventions (targeted to high-risk populations and specific to severe health conditions), and epidemiological evaluation. Important modifications of this model include community-oriented primary care (Tollman 1991), community-based health education and health promotion (Green and Kreuter 1991), community health development (Steckler et al. 1993), participatory action research (Hugentobler, Israel and Schurman 1992) and other forms of community-oriented public health practice that rely on greater participation of communities and labour—as opposed to government officials and industrial management—to define problems, develop solutions and evaluate their effectiveness. Family farming, fishing and hunting, self-employed work, many small business operations and work in the informal economy are all primarily influenced by family and community systems and occur outside the context of an industrial management system. Community-oriented public health practice is a particularly viable approach to occupational injury prevention in these populations.

Outcomes of Interest

The public health approach to workplace safety moves from the concept of accident prevention to a broader approach to injury control where the primary outcomes of interest are both the occurrence and severity of injury. Injury is by definition physical damage due to the transfer of energy. A transfer of mechanical energy can cause trauma, as in the case of a fall or automobile crash. Thermal, chemical, electrical or radiation energy can cause burns and other injuries (Robertson 1992). Not only is the occurrence of injury of interest to public health practitioners, but so is the severity and long-term outcome of injury. Injury severity can be measured in several dimensions, including anatomical (the amount and nature of tissue damage in various regions of the body), physiological (how close to death the patient is, based on vital signs), disability, impairment of quality of life, and indirect and direct costs. Of considerable importance to injury epidemiologists is anatomical severity, often measured by the Abbreviated Injury Score and the Injury Severity Scale (MacKenzie, Steinwachs and Shankar 1989). These measures can predict survival and are a useful indicator of the energy transferred in severe events, but are not sensitive enough to discriminate between severity levels among the relatively less severe, but much more frequent occupational injuries such as sprains and strains.

Among the least useful, but most common measures of severity is days lost from work following injury. From an epidemiological point of view, lost work days are often difficult to interpret because they are a function of some unknown combination of disability, demands of the job, availability of alternative light work, workplace policies such as sick leave, disability qualification criteria and individual differences in pain tolerance, the propensity to work with pain, and possibly the same factors that motivate attendance. More work is needed to develop and validate more interpretable occupational injury severity measures, particularly anatomical scales, disability scales and measures of impairment in the various dimensions of quality of life.

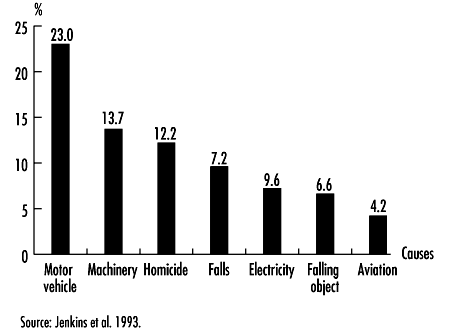

Unlike traditional safety practice, the public health community is not restricted to an interest in unintentional (“accidental”) injuries and the events that cause them. Through looking at the individual causes of fatalities in the workplace, it was found, for example, that in the United States, homicide (an intentional injury) is the leading cause of death at work among women and the third leading cause among men (Baker et al. 1992; Jenkins et al. 1993). Such fatalities are very rare events in individual workplaces and thus their importance is often overlooked, as is the fact that motor vehicle injuries are the single leading cause of fatal injuries on the job Based on these surveillance data, injuries and death due to violence in the workplace and to motor vehicle crashes are priorities in the public health approach to occupational injury prevention in the United States.

Leading causes of occupational injury death, United States 1980-1989

Assessment in Public Health

Assessment in public health is a multidisciplinary effort which involves surveillance, aetiological research, and community and organizational needs assessment. The purpose of injury surveillance is to identify high-risk populations, to identify injuries with significant public health impact, to detect and monitor trends and to generate hypotheses. Surveillance programmes can collect data on injury fatalities, non-fatal injuries, incidents with injury potential, and exposure to hazards. Data sources for occupational injury surveillance include health care providers (hospitals and physicians), death certificates, medical examiner/coroner reports, employer-based reporting to departments of labour or health, workers’ compensation agencies, periodic surveys of employers or households, and individual corporate records. Many of these reports and records are required by law but often offer incomplete information due to a lack of coverage of all workers, incentives to under-report, and a poor level of specificity in injury details.

In-depth investigations of individual incidents employ a variety of approaches which permit the use of expert judgement to draw conclusions about what caused the event and how it could have been prevented (Ferry 1988). Preventive action is often taken based on the findings from a single incident. Rate-based surveillance, on the other hand, has a broader significance than the individual incident. Indeed, some information from traditional accident investigations can have little epidemiological interpretation when aggregated into statistics. Accident investigation in the tradition of Heinrich (1959), for example, often produces statistics indicating that in excess of 80% of industrial injuries are caused solely by unsafe acts. From an epidemiological point of view, such statistics are difficult to interpret except as a survey of value judgements, and are rarely included in rate-based surveillance. Many other risk factors such as shift work, work stress, poorly designed work environments and so on, are often not included in investigation forms and thus are not considered in examining statistics on injury causes.

One of the primary purposes of surveillance is to identify high-risk groups in order to target further investigation and prevention. Injuries, like infectious and chronic diseases, have distinct patterns of risk that vary by age, sex, race, geographic region, industry and occupation (Baker et al. 1992). In the United States during the 1980s, for example, surveillance by the National Institute for Occupational Safety and Health (NIOSH) revealed the following high-risk groups for occupational injury fatality: males; elderly workers; blacks; workers in rural Western states; transportation and materials moving occupations; farming, forestry and fishing occupations; and labourers (Jenkins et al. 1993). Another important aspect of surveillance is to identify the types of injury that occur with the greatest frequency and severity, such as the leading external causes of work-related injury fatality in the United States . At an individual company level, problems such as homicide and motor vehicle fatalities are rare events and thus are seldom addressed by many traditional safety programmes. However, national surveillance data identified these among the three leading causes of occupational injury fatalities. Assessing the impact of non-fatal injuries requires the use of severity measures in order to make meaningful interpretations. For example, back injuries are a common cause of lost days of work, but an infrequent cause of hospitalization for work-related injuries.

Surveillance data alone do not represent a complete assessment in the public health tradition. Particularly in community-oriented public health practice, needs assessment and community diagnosis using surveys, focus groups and other techniques are important steps to assess what problems workers or communities perceive are important, what are the prevalent attitudes, intentions and barriers regarding the adoption of prevention measures, and how an organization or community really functions. A community-based agricultural safety programme, for example, might need to identify whether or not farmers perceive that tractor rollovers are a critical problem, what barriers such as financial or time constraints may prevent the installation of rollover protective structures, and through whom an intervention strategy should be implemented (e.g., trade association, youth organization, organization of farm wives). In addition to a diagnosis of the community, organizational needs assessment identifies an organization’s capacity, workload and constraints to implement fully any already existing prevention programmes such as the enforcement activities of a governmental department of labour (or health) or the safety department of a large corporation.

Investigating the aetiology or causation of loss incidents and injuries is another step in the public health approach to occupational injury control. Such studies of occupational disease have been the mainstay of developing disease-control programmes in the workplace. Aetiological research involves the application of epidemiology to identify risk factors for injury. It also involves applied social sciences to identify the determinants of organizational and individual behaviours that lead to unsafe conditions. Epidemiological research seeks to identify modifiable risk factors through the use of controlled, usually observational study designs such as the case-control study, the cohort study, the panel study and the cross-sectional study. As with epidemiological studies of other acute health events (e.g., asthma attacks, sudden cardiac arrests), aetiological research on injuries is challenged by the need to study either rare or recurrent events that are highly influenced by situational exposures that occur immediately before the event (e.g., distraction by impact noise) and by social and behavioural constructs that are difficult to measure (e.g., safety climate, job strain) (Veazie et al. 1994). Only recently have epidemiological and statistical methods been developed to accommodate the study of these types of health events.

Epidemiological studies that focus on the occurrence of injury are expensive and are not always needed. It does not require a controlled epidemiological study to document the impact of a lack of machine guarding on amputations due to a particular machine; a series of case investigations would suffice. Similarly, if an easily measurable individual behaviour such as failing to use a seat-belt is already a known risk factor, then studies focusing on the determinants of the behaviour and how to improve usage rates, are more useful than studying the injury. However, controlled epidemiological studies of injury and injury severity are needed to provide an understanding of a variety of causal mechanisms that are responsible for decrements in the performance of humans or technology that are difficult to measure. The effect of noise exposure or shift work, for example, on the risk and severity of injury is unlikely to be quantified by case investigations or by studies of easy-to-measure behaviours.

A recent review of studies on risk factors of occupational injuries revealed that age, job title, physical attributes or impairments and experience in the job or task were the most commonly studied human variables (Veazie et al. 1994). Shift work and scheduling were the most commonly studied job content variables. The work environment was the least studied. Most environment factors related to design features or recognized material hazards. Some studies examined factors in the organization and social environment. A few studies evaluated physical stressors such as heat and noise exposure as risk factors for injury. Many of these studies were of poor methodological quality, and few were replicated in different populations. Thus, little is known about risk factors for injury at work, except for the most obvious immediate causes. Future research may benefit by examining the impact on injury rates of risk factors predicted by theory in human factors, ergonomics, occupational stress and organizational behaviour. These may include design and scheduling of tasks and jobs, psychosocial factors (e.g., worker control, social support, psychological demands), and organizational structure and change (e.g., continuous quality improvement and management commitment to safety).

The public health approach also integrates injury epidemiology with the applied behavioural sciences (particularly health promotion, health behaviour and health policy research) to identify the modifiable, environmental reasons for unsafe worker behaviour and, most important, for behaviours on the part of employers and managers that lead to the creation and persistence of hazards. In the large organizational setting, this effort must involve research in organizational behaviour and industrial psychology. Thus, the assessment phase in the public health approach involves epidemiological surveillance, in-depth investigations, community and organizational needs assessment, and aetiological research based on the application of epidemiology and applied behavioural sciences.

Prevention Strategies

A number of principles guide the selection and implementation of prevention measures in a public health approach to injury control. These include:

(1)The importance of basing prevention measures on prior assessment and evaluation. The first principle acknowledges the importance of selecting interventions that are targeted to have a high impact on community health status and are likely to be successfully implemented. Thus, interventions selected on the basis of a thorough assessment phase, rather than merely common sense, are more likely to be effective. Interventions that have been demonstrated as effective in the past are even more promising. Unfortunately, very few occupational injury interventions have been scientifically evaluated (Goldenhar and Schulte 1994).

(2)The relative importance of control measures that automatically protect the worker. The second principle emphasizes the continuum between active and passive protection. Active protection is that which requires constant repetitive individual action; passive protection offers relatively automatic protection. For example, seat-belts require individual action to initiate protection each time someone gets into a vehicle. An air bag, on the other hand, bestows protection on a vehicle occupant without any initiating action—it automatically protects that person. Active interventions require modifying and sustaining individual behaviour change, which has been the least successful of injury prevention strategies to date. This principle is similar to the traditional hierarchy of controls in occupational safety which emphasizes the importance of engineering controls over administrative controls, personal protective equipment and training.

(3)The importance of behaviour modification rather than education. The third principle recognizes the importance of behaviour modification and that not all hazards can be engineered out of the environment at the manufacturing stage. Modification of the behaviour of employers, managers and employees is central, not only to the installation and maintenance of passive protection, but to most other occupational injury control strategies as well. Another important aspect of this principle is that classroom instruction, posters, pamphlets and other forms of education that merely seek to increase knowledge, usually have little effect on behaviour when used alone. Most health behaviour theories applied in health promotion focus on a variety of factors that motivate behaviour change other than awareness of a physical hazard or safe behaviour. The Health Belief Model, for example, emphasizes that self-protective behaviour is most influenced by the perception of risk, the perception of severity and the perception of the benefits and barriers associated with taking protective action (Green and Kreuter 1991).

While credible educational messages may alter some of these perceptions, sometimes the best way to alter these perceptions is to change the physical and social environment. A potentially effective approach to behaviour modification is to redesign equipment and the physical environment to make safe behaviour easier, quicker, and more comfortable or socially desirable than unsafe behaviour. If the layout of machine shop equipment is designed to make walking through hazardous zones difficult and unnecessary, then this unsafe behaviour will be reduced. Similarly, if hard hats are designed to be comfortable and to enhance the social image of the construction worker, they may be used more often.

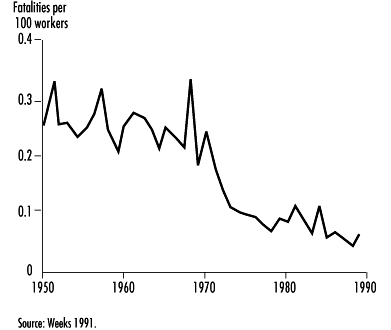

The social environment can also be modified to change behaviour. For example, legislation and enforcement is another far-reaching strategy in injury prevention that changes behaviour and extends beyond education alone. Seat-belt laws and laws requiring the use of infant safety seats, for example, have dramatically reduced motor vehicle fatalities in the United States. The effect of legislation and enforcement on occupational safety, however, is less well-described. One notable exception is the documented clear, dramatic decline in US mine fatalities that followed the implementation of the Federal Coal Mine Health and Safety Act of 1969 . The resources and administrative authority devoted to mine safety enforcement is, however, much greater than that available to most other agencies (Weeks 1991).

The effects of coal mining regulations on underground coal mining mortality rates, United States 1950-1990

Well-designed occupational safety training often involves modifying the social environment by including a role modelling process, incentives, and feedback on safety performance (Johnston, Cattledge and Collins 1994). Another form of training, labour education, represents an altered social environment (Wallerstein and Baker 1994). It empowers workers to recognize hazards and to modify the behaviour of their employers so as to reduce those hazards. While education alone is not usually sufficient, it is usually a necessary component of any injury prevention programme (Gielen 1992). Educating employers and employees is a necessary part of the implementation of a specific injury prevention programme. Educating legislators, policy makers, health care providers and others is also important to initiating and sustaining community-wide injury prevention efforts. Indeed, interventions most likely to succeed in the field use a multifaceted approach which combines environmental modifications with policy changes and education (National Committee for Injury Prevention and Control 1989).

(4) Systematic consideration of all available options, including those that reduce not only injury occurrence but the severity and long-term consequences of injuries. The fourth principle is that the process of choosing interventions should systematically consider a wide range of options. The choice of countermeasures should not be determined by the relative importance of the causal factors or by their earliness in the sequence of events; rather priority must be given to those which most effectively reduce injury. A useful scheme for systematically considering injury control options was proposed by Haddon (1972). The Haddon Matrix reveals that interventions targeted at humans, the vehicles which can transfer damaging energy (e.g., cars, machinery), or the physical or psychosocial environment may operate to control injury in the pre-event, event or post-event phases. the application of the Haddon Matrix to the problem of preventing motor vehicle injuries, which are the leading cause of occupational injury fatalities in many countries.

The Haddon Matrix applied to motor vehicle injuries

|

Phases |

Factors |

||

|

|

Human |

Vehicles and equipment |

Environment |

|

Pre-event |

Educate public in the use of seat-belts and child restraints |

Safe brakes and tires |

Improved road design; restrict alcohol advertising and availability at gas stations |

|

Event |

Prevention of osteoporosis to decrease likelihood of fracture |

Air bags and a crashworthy vehicle design |

Breakaway utility poles and crash barriers |

|

Post-event |

Treatment of haemophilia and other conditions that result in impaired healing |

Safe design of fuel tank to prevent rupture and fire |

Adequate emergency medical care and rehabilitation |

Source: National Committee for Injury Prevention and Control 1989.

Traditional occupational safety interventions most often operate in the pre-event phase to prevent the initiation of an incident with potential to cause injury (i.e., an accident). Event phase interventions such as building cars to be more crashworthy or using safety lanyards while working at elevations, do not prevent accidents, but minimize the probability and severity of injury. After the event is over—the cars in a crash have stopped moving or the worker has stopped falling—post-event interventions such as first aid and prompt transport to appropriate surgical care seek to minimize the health consequences of injury (i.e., the probability of death or long-term disability).

In the public health approach, it is important to avoid getting locked into one phase of the matrix. Just as injury is multifactorial in causation, prevention strategies should address as many phases and aspects of injury as possible (but not necessarily all). The Haddon Matrix, for example, emphasizes that injury control is not limited to preventing accidents. In fact, many of our most effective control strategies do not prevent accidents or even injuries, but can considerably reduce their severity. Seat-belts and air bags in cars, safety helmets, fall protection in construction, rollover protective structures in agriculture, and emergency eyewash fountains in the laboratory are but a few examples of event-phase strategies that do nothing to prevent an accident from occurring. Instead, they reduce the severity of injury after the accident has been initiated. Even after the anatomical damage has been done, much can be done to reduce the risk of death and long-term disability. In the United States, it has been estimated that many major trauma deaths could be prevented by systems that minimize the time delay between injury and definitive surgical care. This broader framework is called injury control and goes far beyond traditional accident prevention. A commonly used phrase to illustrate this point is “Injuries are not an accident”. They can be predicted and their impact on society controlled.

Another useful scheme often used for systematically considering injury control options is Haddon’s Ten Countermeasure Strategies (Haddon 1973). how these strategies can be applied to controlling injury from falls in construction. As shown, not all strategies will be applicable for specific problems.

Haddon’s Ten Countermeasure Strategies applied to injuries due to falls in construction

|

Countermeasure |

Intervention (and relevant notes) |

|

Prevent the creation of the hazard. |

Do not construct buildings—generally not a practical option, to be sure. |

|

Reduce the amount of the hazard brought into being. |

Lower the height of construction project to below fatal levels—usually not practical, but may be possible in some work zones. |

|

Prevent the release of the hazard. |

Install non-slip walking surfaces on roofs and other heights. |

|

Modify the rate of release of the hazard from its sources. |

Use safety lanyards. Use safety nets. |

|

Separate the hazard from the worker by time and space. |

Do not schedule unnecessary foot traffic near fall hazards until the hazards are abated. |

|

Separate the hazard from the worker by physical barriers. |

Install guardrails on elevated surfaces. |

|

Modify basic qualities of the hazard. |

Remove sharp or protruding projections on the ground surface where workers can fall—practical only for very low heights. |

|

Make worker as injury resistant as possible. |

Require, e.g., safety helmets. |

|

Begin to counter damage done by the hazard. |

Apply first aid. |

|

Stabilize, treat and rehabilitate worker. |

Develop a regionalized trauma system; provide for effective rehabilitation and retraining. |

Evaluation in both applied social sciences and epidemiology is “a process that attempts to determine as systematically and objectively as possible the relevance, effectiveness and impact of activities in light of their objectives” (Last 1988). Evaluation is an essential component of public health practice. It occurs at two levels. The first level relies on surveillance systems to determine whether or not entire communities have met their disease and injury reduction objectives, without attempting to determine what caused the observed changes. Federal, state and local government agencies in the United States, for example, have set objectives for the year 2000. One of these objectives is to reduce work-related injures resulting in medical treatment, lost time from work, or restricted work activity to no more than 6 cases per 100 full-time workers per year. Progress in meeting these objectives will be monitored with the national surveillance systems in place.

The second level of evaluation focuses on determining the effectiveness of policies, programmes and specific interventions. Ideally, this requires the application of controlled experimental or quasi-experimental study designs. Mohr and Clemmer (1989), for example, conducted a time series study of injury rates in those mobile off-shore oil rigs that opted to implement a new technology to assist workers in connecting drill pipes, compared with rates in those rigs that did not have the new technology. Although injury rates were going down over the period of the installation of the new equipment, the authors were able to attribute a decrease of 6 injuries per 100 workers per year to the new safety equipment and to demonstrate that the savings from injury prevention resulted in a full recovery of the initial capital and installation costs within 5.7 years. Unfortunately, this type of scientific evaluation of programmes and interventions in occupational health and safety is rare and often methodologically flawed (Goldenhar and Schulte 1994).

Summary

The above-mentioned programme demonstrates well the various components in the public health approach to reducing injuries in the workplace. Assessing the injury problem and establishing an ongoing surveillance system was an essential part of this and earlier studies of injuries on oil rigs that were conducted by these authors. The subsequent development of a simple engineering prevention strategy was then followed by a rigorous evaluation strategy which included an evaluation of cost savings. Such studies have been the mainstay of the public health approach to the prevention of other occupational diseases. In the future, the integration of occupational injury prevention into the assessment, intervention and evaluation phases of public health practice has the potential to be an important step toward more effective protection and promotion of health in communities.