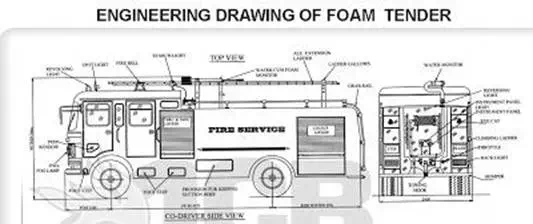

FIRE TENDER

INTRODUCTION:

Major fires major appliances for achieving extinguishment. Rate of application of the firefighting media has got to be proportionate to the size of fire. Major appliances are designed to such capacities as to cater to the needs of firefighting operations. They are mounted on the vehicles, so that, they can reach the site of the fire without loss of much time.

Depending upon the class of fire major appliance has been designed suitably. Water type appliances are common. Specialized appliances are also available to fire fight B, C, D, & E class of Fires.

CRASH FIRE TENDER (CFT):

· Certain vital areas require very prompt attention such as Air Crash Firefighting, I Petroleum fires, where a slight delay in commencement of firefighting operations, results in loss of precious lives and heavy materials losses.

· Keeping this in view Crash Fire Tender was developed. This meets the standards laid down by National Fire Protection Association of USA.

· This appliance finds maximum use at Air Force. & Navy establishments besides some petrochemical units.

· Mounted on Ashok Lay land chassis, CFT has water tank capacity of 6500 liters with a foam tank of 800 liters. It carries 2 BCF extinguishers of 50 kg capacity each connected with a Hose Reel.

· Foam Expansion Ratio is 1: 8 with a standard Foam Making Branch Pump Capacity is 4000 1pm at 8.5 kg/cm2 with exhaust ejector primer.

· Monitor capacity is 30,000 1pm at 10.5 kg/cm2 with throw of 50 meters.

· Besides it carries adequate accessories kept in spacious lockers and can carry 5 persons.

OPERATION:

Placement:

· Take the Fire Tender, to the scene of fire and place it in the direction of the wind, after reversing it i.e., keeping the pump side facing the scene of fire.

· Power Take Off:

· Change the position of the lever provided at the back of driver seat to take power off the vehicle engine and to divert the same to the pump.

Priming:

· Open the suction valve of the pump. In case water is available in the water tank, simply open the priming valve and allow all air present in the pump casing to come out of the waste pipe followed by continuous stream of water. Then close the priming valve.

· In case no water is available in the water tank, connect the suction hose and immerse the other end fitted with a foot valve, in the source of water. Divert exhaust gases to the "primer" open the priming valve. Allow all air to come out of the waste pipe till steam starts coming out of it.

Line Out:

· Connect fire hoses and other required fitting as per drill procedure.

· Raise the throttle to get the required pressure.

· Open water for engine cooling. Step V:

Knock off and Make up:

· After the fire fitting is complete disconnect the fire hoses and fittings.

· take off power from pump and give it to vehicle engine

· keep all components in their respective places