PRIMERS

INTRODUCTION:

The devices used to exhaust air from the suction and the casing is known as priming devices. After the pump is primed the atmospheric pressure is able to force the water to reach the pump entry.

Various types of the primers are discussed here.

RECIPROCATING PRIMERS:

These are reciprocating pumps which develop higher pressure by the direct action of plunger on the fluid (liquid or gas) confined in a cylinder and forcing the fluid out from the discharge.

Working:

The piston is driven from the main pump drive shaft by its engagement with the help of a, crankshaft & a lever. The priming pump inlet is connected to the delivery side of the main pump with a priming valve (air valve). The priming value is normally kept closed by means of spring, thus isolating the priming pump from the main pump.

During down stroke the air moves above the piston though the valve in the piston. Again in the up stroke; the air above the piston is forced out though the outlet drain pipe. By the up & down movement of the piston in the cylinder entire amount of air is first pushed out followed by water.

These primers find the maximum usage in fire service pumps mounted on vehicles like Fire Tenders.

Principle:

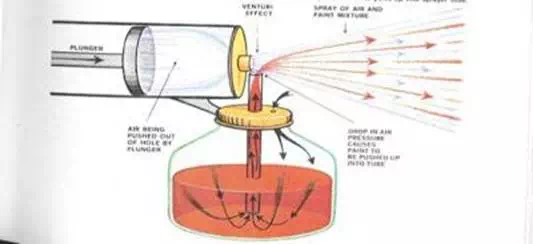

When a fluid (liquid or gas) under high velocity passes through a throat into a chamber of larger diameter a negative pressure is created around the throat.

Construction:

The essential parts of a jet pump are

● The nozzle

● The diffuser

The purpose of nozzle is to convert pressure energy to velocity energy. The purpose of diffuser, a mixing chamber of motive gases and the entrained fluid, is to convert the velocity energy back to pressure energy.

Jet pumps have no moving parts and thus practically no maintenance is required. But they do need high pressure motive fluid which is usually expensive to supply.

Working:

● When the pump is to be primed the priming value is opened and the exhaust valve closed.

● The purpose of closing the exhaust valve is to divert the exhaust gases from their normal passage down the exhaust pipe to the silencer and conduct them to the nozzle of the jet pump which is connected to the casing of the pump as shown in the figure.

● The exhaust gases discharge from this nozzle into a throat pipe.

● On the principle of the jet pump, the air from suction and pump casings through the priming value, is drawn out When all air from suction side is drawn out, water follows which can be seen in the form of steam coming out of the diffuser pipe.

● At this point the priming valve should be closed and exhaust value opened back.

● Both these actions take place simultaneously by a lever mechanism.

● In Case of Fire Tender Exhaust Gas of Engine (From Silencer) Is Used to Draw Water from Reservoir to The Main Pump

● When Steam Starts Coming from Injection Primer (Due to Hot Engine Exhaust) We Can Conclude That the Main Pump Is Now Primed with Water.

● So, Close the Prime Valve, Start Main Pump of Fire Tender and Open Delivery Valve.

A water ring primer may be automatic in action being driven directly from the main pump shaft. This is the primer widely used in the fire service as this can be arranged for either automatic or hand operated.

Principle:

The rotating parts move in relation to the casing so as to create a space which first enlarges, drawing in the fluid in the suction line is sealed and then reduces in volume, forcing the fluid through the discharge ports at a higher pressure.

Construction:

- Mounted on the casing of the main pump it is constructed with the following parts.

- A rotor or impellor with radial vanes. This has two suctions and two

- discharge ports.

- Oval shaped casing

- Stationary boss having two suctions and two discharge ports.

- A waste pipe connected with discharge pipes of two outlet ports.

Working:

● As the rotor revolves, a small quantity of water which is kept in the casing is thrown by centrifugal force thus leaving a vacuum between the boss of the rotor and the water.

● When the inlet ports in the casing and those in the rotor coincide, air is drawn in by the vacuum and carried around until the outlet ports are reached.

● Here as the casing narrows, the fluid is forced out, thus driving out the air through these outlet ports.

● The inlet and outlet ports being duplicated, extremely rapid, and effective priming is achieved.

● Since the impeller is located centrally in the oval shaped casing there are two pumping actions in one revolution.

Advantages:

● It has large exhausting capacity

● It gives extremely large rapid and effective priming

● It is suitable for low water levels

● No skills is required in operating