CHARECTRISTICS, REPAIR AND HANDLING

CHARACTERISTICS OF HOSE:

The main characteristics essential for a good fire fighting hose are:

(i) Flexibility:

Hose must be sufficiently flexible to

● Enable it to be handled with ease.

● Enable it to be made up into a smooth and tight role. The crease at the edges should be uniform and regular so that the hose does not bulge on one side after wobbling repeatedly.

(ii) Durability:

● Hose must be a strong enough for it to be reliable during the use.

● The materials used in its construction must have high resistance to abrasion and should be able to withstand the rough usage.

● A tough plastic outer cover will provide additional protection to the jacket and prolong its life.

(iii) Resistance to rot:

● Hoses made of natural fibres are prone to be affected by rot or fungi. These must be treated with rot proofing agents such as zinc chloride, penta chloro phenyl laurate, 1.5% by mass or penta chloro phenyl 1- hydroxyl isopropyl, etha (Max 2% by mass)

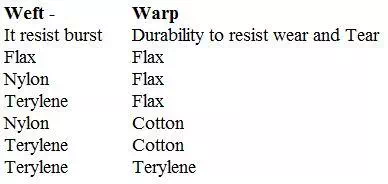

MATERIAL USED

CARE AND MAINTENANCE OF HOSE

(i) Store in a cool dry and well-ventilated place.

(ii) Hoses should be cleaned & dried periodically

(iii) Rubber lined hoses should be cleaned by passing water through them and dried

on towers, periodically. These should not be exposed to hot dry air or sun rays

for long periods.

(iv) Hoses should be stored in long folds or in figure eight position.

(v) The folds should be changed periodically.

(vi) Hoses contaminated with acids / alkalies or oils should be cleaned and dried before Storing.

(vii) Hoses should be drained by under running and not be walking over them.

CLEANING PROCEDURE

(i) Normally the cleaning is done with water alone.

(ii) If the hose is contaminated with grease / oil add a little soda in water and clean.

(iii) If the hose is contaminated with thick grease / acid / oil, use saw dust and fine

sand to rub off the sticky substances.

DRYING PROCEDURE

● Natural: In sheds constructed in such a way as to permit the entry of air as much as possible. But no rain should enter it. The hoses are hung from towers / or hooks at the roof of the shed with the help of pulleys.

● Mechanical: In chambers of brick construction. Provision is made to accommodate 20 lengths of hoses. All the hoses are coupled to manifold through which warm air is blown.

● An exhaust fan is fitted to the chamber so that constant air is circulated.

REPAIRS

After use the hose should be inspected carefully to detect any damage and to repair the same for future use. Every damage such as pin holes should be marked, and the defective hoses should be rolled with male coupling inside for the sake of identification.

Generally, the following repairs are carried out.

● Hose coverings & Bandages: Leather gaiters and canvas bandages are applied

● where the hose appears to be weakened.

● Darning: Pin holes are generally repaired by darning some strands of flex. A

● patch should be placed on the same.

● Patching: Leaks in the hose are satisfactorily repaired by patching.