What is Safety Sampling?

Safety Sampling is a systematic sampling of particular dangerous activities, the process of the area. It’s a method of measuring hazard or accident potential by random sampling and by counting safety defects while touring (Safety Tour) specified location by a prescribed tour of 15 minutes at the weekly intervals.

The quantum of defects noticed is used to portray trends in a safety situation. The point on safety sampling sheet includes items such as non-use of personal protection, obstructed fire exit, environmental factors, lighting, ventilation, temperature, faulty hand tools, guarding position, Housekeeping machinery condition, etc.

The results are collected by the safety officer and presented in graph form to monitor the effectiveness of the safety program.

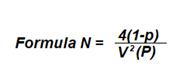

Gives the number of observation N,

When the percentage of unsafe operations P and value of accuracy V (normal value = 10%) are known. For example, if during the preliminary survey of 60 observations, 20 were found unsafe then

This means 812 sample observations would be required to ascertain various unsafe practices with an accuracy of 10%. If 200 observations are possible in one tour, four tours (three tours of 200 and last tour of 212 0bservation) will be required for satisfactory results.

This technique was first employed by American chemical plants and then by ICC’s Dyestuffs Division in UK. It is based on Heinrich’s ratio 1:29:300 opportunities must be observed before one lost-time accident. It is based on samples and not on detailed surveys.