Geotechnical Factor of Safety and Risk

Factor of Safety (FoS) is a measure used in engineering design to represent how much greater the resisting capacity of a structure or component is relative to an assumed load. With respect to slope stability, FoS is the ratio of shear resistance to driving force along a potential failure plane. A FoS greater than 1.0 implies the available shear strength to resist failure is greater than the driving force to initiate failure.

There is no means of quantitatively measuring the “real” FoS of a particular slope at a given time. Therefore, FoS of a slope is estimated based on industry standard analytical methods with assumed material parameters inferred from various data sources (laboratory, drilling, empirical correlations) under various loading conditions (e.g. static, post-earthquake, construction).

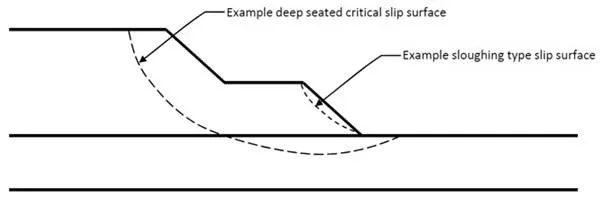

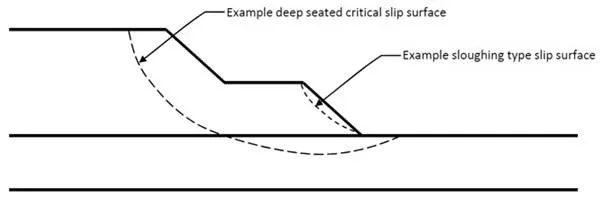

The FoS is estimated for a number of slip surfaces for a given analysis scenario ranging from deep seated (e.g. through foundation) or shallow, sloughing failures – refer to the image below.

Slip surface examples

In cases where shallow sloughing failures have the lowest FoS, they are typically ignored when selecting the critical FoS for a dam because the consequence of the slough is not significant with respect to the stability of the structure.

FoS is used by designers, dam owners and regulators to quantify dam safety, but it is not directly correlated to the risk (i.e. the likelihood and consequence) of failure. For example, a dam with a FoS of 1.4 does not necessarily have a higher probability of failure than a dam with a FoS of 1.6. In their presentation at the Australian National Committee on Large Dams (ANCOLD) 2017 conference, Herza et al. agreed that FoS and probability of failure have a weak correlation:

“Interestingly, the minimum recommended factors of safety used today do not take into account the potential consequences of dam failure or the uncertainties in input values, and are based on the loading conditions only. Yet, several authors have demonstrated that a higher factor of safety does not necessarily result in a lower probability of failure, as the analysis also depends on the quality of investigations, testing, design and construction.”

The confidence in FoS values can vary significantly, depending on the uncertainty of assumed material parameters and the engineers’ experience in defining assumptions and interpreting the results. As these factors change, the risk associated with a specific FoS value can vary between sites, dam owners, or even different segments of a single dam or slope.

A dam or slope with a lower FoS derived from analyses with a high degree of confidence and reliability may be “safer” or “lower risk” than a dam with a higher FoS derived from less reliable analyses. For this reason, it is necessary to involve experienced dam design professionals in the material characterization, analysis, sensitivity and interpretation of the results.

The application of FoS criteria by engineers in dam design has evolved over time and is being reviewed by professional associations following recent tailings dam failures. Accepted industry standards, such as Canadian Dam Association Guidelines, will continue to recommend minimum FoS values for use in design. However, the selection of appropriate FoS values, in addition to complying with accepted practice and regulations, must be supported by a comprehensive dam safety risk management system. This approach is becoming recognized across the industry and should be adopted for all active projects.

KCB engineers have worked on the design of tailings, hydro power and water dams since the company was founded in 1950. We helped to revolutionize the design of modern tailings storage facilities and our engineering approach continues to be the hallmark of international practice. Today, we provide solutions for some of the largest, most technically challenging tailings storage facilities in the world. We can help you determine the geological and geotechnical setting of your tailings facility, and design and monitor the construction of your tailings impoundment and related infrastructure.