TYPES OF FIRE EXTINGUISHERS

PORTABLE FIRE EXTINGUISHERS Introduction:

Portable fire extinguishers are also known as chemical fire extinguishers or First Aid Fire Fighting Appliances.

These extinguishers are highly useful to prevent a small fire from becoming a big one, provided these are used when the fire is just in its starting stage, say within first five minutes. These are light weight, small in size which can be easily carried by hand.

Larger models of certain types are also available which are known as "engines". These are mounted on trolleys, which can be moved manually or toed to motor vehicles.

WATER TYPES EXTINGUISHERS

(I) SODA ACID EXTINGUISHER:

- not used in presents .... it has been banned

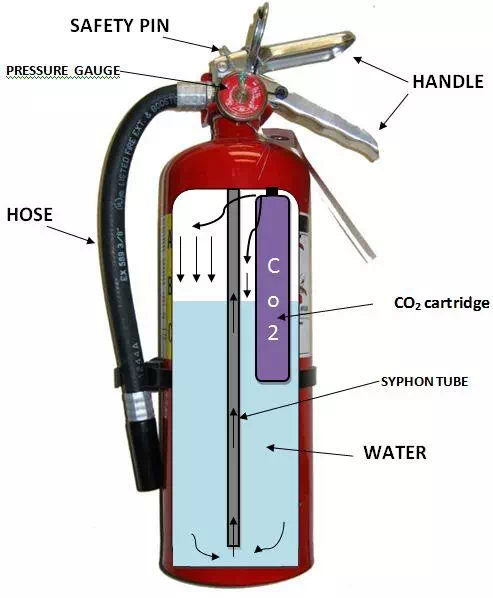

(II) WATER TYPE (C02 Gas Expelled):

(A) CONSTRUCTION

These extinguishers are identical in appearance and construction to SODA ACID type of extinguishers. The only exception is that instead of acid phial these extinguishers are provided withC02 cartridge which is screwed to the cap of the extinguisher. The C02 cartridge has a sealing disc. The plunger has a piercing type nail attached to it in such a way that it will puncture the sealing disc of CO, cartridge when pushed down.

There are two types of this extinguishers based on their position for operation.

- Upright type: These are provided with a dip pipe (siphon tube) attached to the outlet point with or without a discharge hose pipe.

- Invertible type : There is no dip pipe in this type of extinguishers and no discharge pipe is provided.

A) APPLICATION:

Class A fires involving ordinary solid carbonaceous fuels.

Capacity: Portable - 9 Litres

Mobile - 50 Litres, 150 Litres

(C) OPERATION:

(a) Remove the safety clip

(b) Remove from the wall / stand mountings by holding the top handle with the left hand.

(c) Place it on ground at 6 meters or less from the scene of fire.

(d) Hold the pipe in left hand and press the knob hard enough to puncture the C02cartridge seal disc.

(e) Direct the jet at the base of the fire by lifting the extinguisher with tight hand. Move around the fire to extinguish the last clinker. Use the entire contents of the extinguisher.

(f) Place the empty extinguisher in the horizontal position after use.

(D) PERFORMANCE:

At pressing the knob, C02 gas cartridge gets punctured. C02 gas pressurizes the extinguisher up to 6 to 7 kg/cm2 pressure. The water in the outer vessel is thrown out through the squeeze nozzle. The throw is about 20 feet for the first minute and 95% of the total water comes out in 2 minutes.

(E) RECHARGING:

- Open the cap

- Clean the extinguisher and its parts thoroughly.

- Pour clean water in Other container up to maximum filling mark.

- Replace CO cartridge with a new one.

(F) TESTS:

(i) (a) Check one in three months / Inside & Outside of container for any corrosion or erosion.

Check the weight of C02 cartridge. Replace if the loss is more than 10%. The weight is marked on neck of every cartridge.;

(b)Check all movable parts for their free movement.

(ii) Check discharge performance once every year.

(iii) Test the container hydraulically at 25 kg /cm2 pressure and the tube if fitted

once 4 years.

(G) LABELING:

Every extinguisher must be clearly labeled in a permanent manner to indicate

(i) The name of the manufacturer

(ii) Capacity

(iii) year of manufacture

(iv) Method of Operation

(v) The class of Fire.

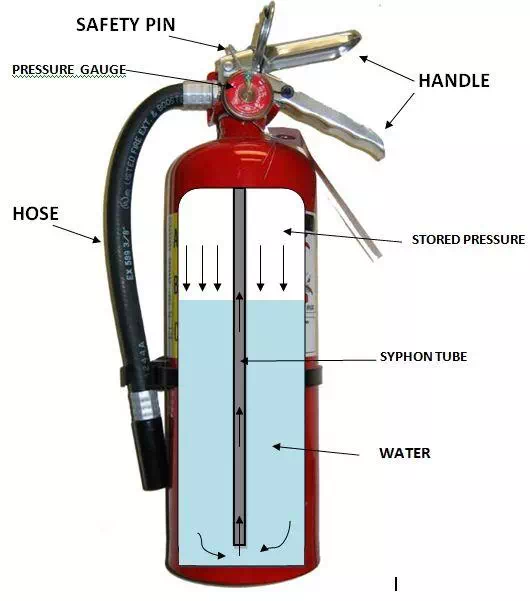

III) STORED PRESSURE TYPE OF WATER EXTINGUISHER:

the constant air pressure extinguisher shown in fig. above is filled with water. Dry air is including through airline till the desired pressure is built-up. The airline is removed and the Container is air tight sealed. While actuating, safety pin is withdrawn, and valve lever is depressed resulting in a jet of water through the hose.

Capacity: Portable - 9 Litres

Mobile - 50 Litres, 150 Litres

1 ) chemical foam extinguisher

2) mechanical foam extinguisher

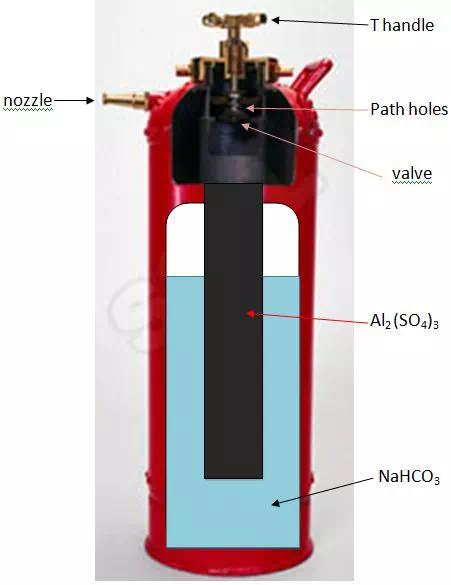

1) CHEMICAL FOAM EXTINGUISHER:

6 NaHC03 + Al2 (S04)3 = 3 Na2S04 + 2 Al(OH)3 + 6C02

[A] CONSTRUCTION:

This extinguisher has a cylindrical outer container made of best sheet of steel of 1.25 mm thickness with lead coating inside. This is tested at 25 kg/cm2 hydraulic pressure for 5 minutes. A partly channeled spindle passes through the centre of brass cap. The one end of the spindle carries a sealing disc which closes the inner container; the other end is connected to a "T" handle. When this handle is pulled up it opens the seal of the inner container.

The inner container is made of sheet of copper and its capacity is 1 liter. This container rests inside the outer container duly supported at the neck of the extinguisher. There are holes on the top of the inner vessel so that once the "T" handle is lifted up and extinguisher turned upside down the contents will readily mix with the contents of the outer vessel.

A nozzle is provided at the cap of the extinguisher. The handle is also provided at the P-The outer vessel contains 7.8 liters of 8% solution of Sodium bicarbonate while the ner vessel contains 1 liter of 13% aluminum sulphate solution.

[B] APPLICATION:

'B' Class fires involving liquid fuels such as Kerosene Oil, Benzene, Petrol etc.

Capacity: Portable - 9 Litres Mobile - 50 Litres, 150 Litres

[C] OPERATION:

Step -1 : Remove the extinguisher from the wall / stand mounting and take i to scene of fire up to 6 meters away.

Step - II: Shake the extinguisher 3 - 4 times

Step - III: ' Place it on the ground. Lift the 'T handle and give half turn to the left. The lock pin on the shaft of the 'T' handle, will sit in the grove provided for the purpose.

Step - IV: Hold the top handle with right hand and the bottom one with the

Step - V: Turn the extinguisher upside down.

Step - VI: Allow the jet of foam to fall gently on the surface of the burning fuel.

Step - VII; Keep the empty extinguisher in horizontal position and writ* H with a marker pen.

[D]PERFORMANCE:

At turning the extinguisher upside down aluminum sulphate solution of the inner vessel mixes with sodium bicarbonate solution of the outer vessel. The chemical reaction takes place with the formation of multiple compounds which give foaming action. C02 gas is also generated during the reaction which pressurizes the extinguisher to 6 to 7 kg/ cm2 pressure. The contents of the extinguisher are pushed out through a nozzle where atmospheric air is entrained and converting the contents into a rich foam.

The foam is thrown out up to 20 - 30 ft during 1st minute Entire contents are pushed out in 2 minutes.

[E] RECHARGING:

Unscrew the cap. Remove the inner vessel.

Clean the extinguisher thoroughly with water both from inside and the outside.

Clean the outlet nozzle.

Take 7.8 litters of water in a bucket. Add Sodium bicarbonate powder packet supplied by the supplier. Stir well with a wooden rod till entire powder is dissolved.

Pour this solution into the outer vessel.

Clean the inner vessel.

Take one liter of water in a bucket add aluminum sulphate powder as supplied by supplier. Stir well till entire powder is dissolved.

Pour this solution into the inner vessel.

Gently lower the inner vessel into the outer vessel without spilling out any solution from it.

Clean the rubber washer and place it in position

Place T-Handle in the down position. Slightly grease the threads before screwing up the cap.

(F) TESTING:

(a) Physical Inspection: Open the extinguisher every three months to check Vent holes, nozzle, washer etc. for good condition.

(b) Each extinguisher shall be tested by discharge once every year from the date of charging.

(c) The extinguisher shall be tested hydraulically one every 4 years at 25 kg/cm2 pressure for 5minutes.

(G) LABELLING:

Every extinguisher must be dearly labeled in a permanent manner to indicate

(i) The name of the manufacturer

(ii) Capacity

(iii) Year of manufacture

(iv) Method of Operation

(v) The class of Fire.

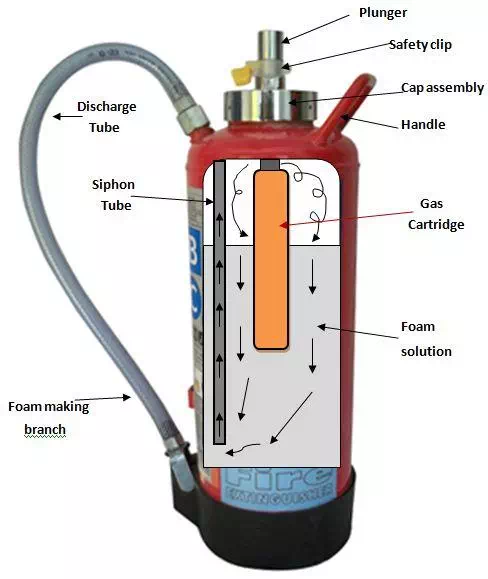

2) MECHANICAL FOAM EXTINGUISHER:

The construction of this type of extinguisher is same as that of C02 Gas expelled type of water type extinguisher. Instead of water, it contains foam compound mixed in water in the ratio mentioned by the supplier.

The operation recharging, maintenance testing & labeling procedures are same as for water type (C02 Gas Expelled) Extinguisher.

Capacity: Portable - 9 Litres

Mobile - 50 Litres, 150 Litres

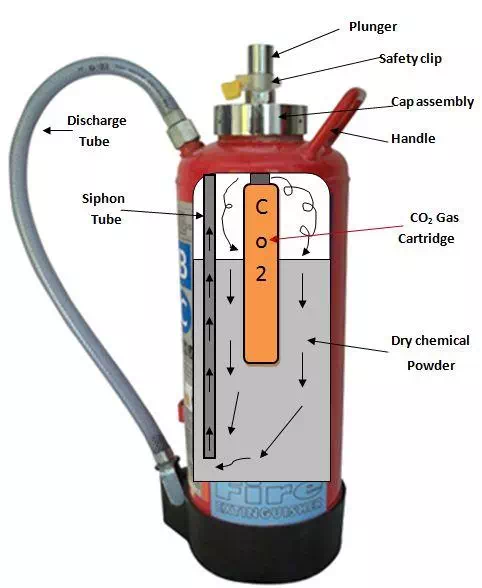

DRY CHEMICAL POWDER EXTINGUISHER (Gas Cartridge Type)

(A) CONSTRUCTION:

- The extinguisher is cylindrical in shape, made of solid drawn steel cylinder.

- -It has a removable internal shell having gas pores and is protected with thin rubber rings and rubber washer at its neck.

- The extinguisher is fitted with a siphon tube connected to the body with a small length of high pressure flexible hose terminating into a squeeze grip type nozzle attached to its end.

- The nozzle is protected with a rubber cap against entry of moisture.

- The expellant is C02 gas in a cartridge which is sealed.

- The C02 gas cartrigde is screwed to the operating head which is' fixed with a piercing mechanism.

- Dry chemical powder is filled in the body in quantitie's as per capacity.

(B) APPLICATION:

All classes of fire except D class which require special composition of powders

Capacity : Portable 1 kg, 2 kg, 5 kg, 10 kg

Mobile : 22.5/25 kg, 50 kg, 75 kg, 150 kg, 200 kg, 250 kg, 300 kg, 500 kg

(C) OPERATION:

Step -1 : Remove the safety clip.

Step - II: Withdraw rubber cap from the nozzle.

Step - III: Hold the squeeze (the lever of) nozzle valve in open position.

Step - IV: Press the plunger and direct the powder into the flame with a fast sweeping motion.

(D)PERFORMANCE:

At the press of the plunger, the C02 cartridge gets punctured. C02 gas is released to pressurize the extinguisher up to 7 Kg/cm2 pressure. The powder in the outer body is pushed out through the nozzle.

(E) RECHARGING:

· Recharging should be done on a sunny day with least humidity in the air.

· Clean the extinguisher body and other parts thoroughly.

· Make the body as dry as possible before filling after unscrewing the cap.

· Fill the outer vessel with recharge powder as supplied by the supplier in quantities according to the size of the extinguisher.

· Place the inner vessel with CO cartridge in the outer vessel.

· Screw back the cap after applying a litde grease on the threading’s. The charge composition varies as follows:

(F) TESTING:

· Gas Cartridge should be weighed once in 3 months

· The extinguisher should be opened and checked against plugging of nozzles, siphon tube, washers, went holes etc. periodically.

· Check all moveable parts for their free movement periodically.

· Body should be hydraulically tested at 25 kg/cm2 once in every four years.

CHARGE COMPOSITION:

(a) Normal DCP Extinguisher

Sodium Bicarbonate - 97%

Magnesium Stearate - 1%

Magnesium Carbonate - 1.5%

Calcium Phosphate v-i - ½ %

(b) Special Powders (For 'D' Class Fires)

(i) Bitumen 45%

Sewage Powder 45%

Aluminum Sulphate 10%

(ii) Sodium Chloride 20%

Potassium Chloride 29%

Barium Chloride 51%

(G) LABELING:

Every extinguisher must be clearly labeled in a permanent manner to indicate

(i) The name of the manufacturer

(ii) Capacity

(iii) Year of manufacture

(iv) Method of Operation

(v) The class of Fire.

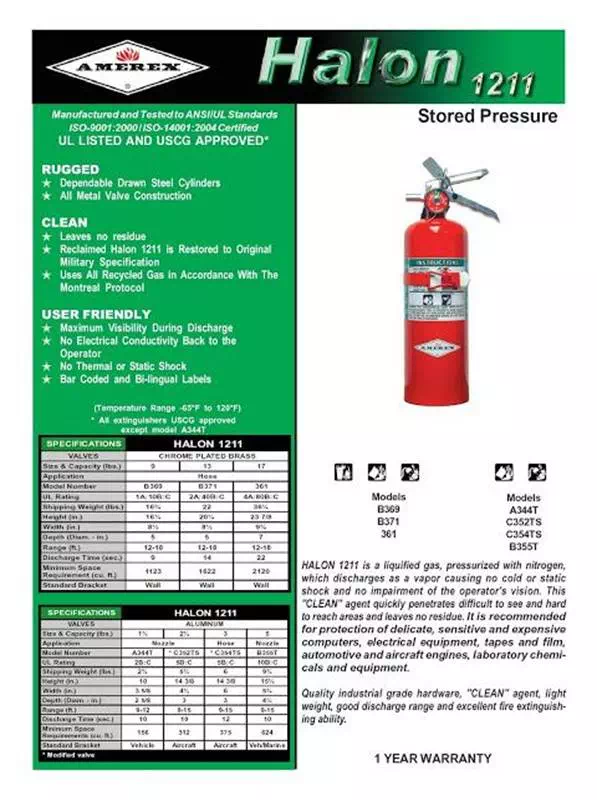

HALON EXTINGUISHER:

- Halon 1211 (BCF) pressurized extinguishers are used for fires on electrical / electronic equipment.

- These extinguishers can be used on Class A, B and C fires.

- It is virtually non-corrosive and non-abrasive.

- It is at least twice as effective on Class B fires as carbon-dioxide, compared on weight of agent basis.

- The extinguishing media contained in these extinguishers is hydrocarbons in which one or more hydrogen atoms have been replaced by atoms from halogen series; Florine, chlorine, bromine or iodine.

- The substitution confers not only non-flammability but also flame extinguishing properties to any of the resulting compounds.

METHOD OF OPERATION:

The extinguishing must be operated and applied to fire in the same way as C02 extinguisher.

APPLICATION: It is suitable for Class K / Class B / Class C fire. Here 1% AFFFF solution is added.

STORAGE EXTINGUISHERS IN OPEN AREA:

- fire extinguisher should be placed in fiber glass or metal cabinets in such a way that bottom is 750mm above the ground level.

- It may be necessary to construct suitable shades or covers to protect the extinguishers in the open from rigors of weather unless these are housed in fiber glass or metal cabinets designed for the purpose.

- where cabinets or shades are used to house the extinguisher in the open, these should be

so designed that removal of these extinguishers are not hampered in an emergency.

STORGAE OF EXTINGUISHERS INSIDE AND UNDER COVER:

Fire extinguishers, whether hung on brackets or kept on shelves, their bottom should be

about 750 mm above the floor level. In no case a fire extinguisher should be placed in a

position where it is likely to gain heat from the surrounding equipment or the process.

MAINTENANCE, INSPECTION AND TESTING :

Routine maintenance, inspection and testing of all fire extinguishers in respect of mechanical parts, extinguishing media and expelling means could be carried out by properly trained personnel at frequent intervals at least once in a month to make sure that these are in their proper working condition and have not been accidentally dischatged or lost pressure or damaged.

Following procedure should be followed for monthly maintenance, inspection and testing.

- clean the exterior of the extinguisher, polish the painted position with wax, polish the brass parts with metal polish, chromium plated parts with silver polish.

- Check the nozzle outlet and vent holes and the threaded portion of the cap for clogging and ensure that the plunger is in fully extended position and is clean.

- Check the cap washer, grease the threads of cap plunger rod and wipe clean.

- Make sure that the extinguisher is in proper condition and is not accidentally discharged. In case of stored pressure extinguisher, pressure gauge is to be checked for correct pressure.

- Check all mechanical parts thoroughly.

ANNUAL INSPECTION (Other than Performance Test)

At longer interval, at least once in a year, a more thorough inspection and maintenance of extinguisher, including chemical charge inside and expellant should be carried out by trained personnel. Any extinguisher showing corrosion or damage to the body internally or externally should be replaced. Faulty, damaged and corroded parts shall be replaced by correct component. Illegible labels should be replaced.

(A) CONSTRUCTION:

The extinguisher consists of two principal parts.

A drawn steel cylinder containing the liquefied CO2 gas charged at the pressure of 744lbs per square inch at 600 F

A control valve which by turning on and off the extinguisher is operated and closed

In addition to this it is also provided with a high-pressure tube and a horn. The horn is designed to stop the entrainment of air with CO and to reduce the velocity. If the horn is not provided, the jet of CO will canny air along with it and act like a blow torch and will increase the intensity of fire.

(B) APPLICATION:

B/C classes of fire involving liquid & gaseous fuels and electrical equipment’s.

(C) OPERATION:

- Take the extinguisher as close as possible to the fire.

- Hold the horn with left hand.

- Open the control valve.

- Direct the jet at the base of the fire with sweeping action from as close as possible to the fire.

Caution

CO2 is an asphyxiating gas and heavy concentration can cause unconsciousness even death.

Not suitable for metallic fires,

The effective range is \Vi to 2Yi meters only. ,

(D) RECHARGING:

Send to manufacturer for recharging

(F) TESTING:

The extinguisher should be tested by weighing six monthly. The weight should be compared with that stamped on the extinguisher. If the loss of weight exceeds 10% it should be sent for recharging.

(G) LABELLING:

Every extinguisher must be clearly labeled in a permanent manner to indicate

(i) The name of the manufacturer

(ii) Capacity

(iii) Year of manufacture

(iv) Method of Operation

(v) The class of Fire.

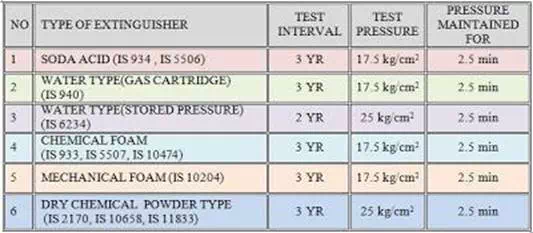

REFILLING SCHEDULE FOR FIRE EXTINGUISHERS AND SCHEDULE FOR OPERATIONAL TEST AS PER IS 2190 - 1992

EXTINGUISHERS TO BE REFILLED/OPERATED OF PERFORMANCE TEST ONCE IN TWO YEARS.

- Portable chemical fire extinguisher foam type.

- Portable chemical fire extinguisher, soda acid type.

- Portable fire extinguisher, water type stored pressure.

- Portable fire extinguisher, mechanical foam type.

ONCE IN FIVE YEARS

- fire extinguisher, water type (gas cartridge)

- Portable fire extinguisher, dry powder (cartridge type)

- Fire extinguisher carbon dioxide type (portable and trolley mounted)

- Higher capacity dry powder fire extinguisher (trolley mounted)

- Dry powder fire extinguishers for metal fires.

NOTES

In corrosive environments, it is desirable to have the discharge test carried out at half the frequency mentioned.

SCHEDULE FOR HYDRAULIC PRESSURE TESTING OF FIRE EXTINGUISHERS AS PER IS 2190 - 1992

E-1 : Every extinguisher installed in premises shall be hydraulically pressure tested as per the schedule given below. There shall not be any leakage or visible distortion. Extinguishers which fails in this requirement shall be replaced.

E-2 : the carbon dioxide type and halon 1211 type fire extinguisher shall be pressure tested every time the cylinder is sent for recharging to the pressure specified in the relevant standers specifications.

FIRE HOSE - types & fitting there of fire service hose