Safety Assessment Strategy for Collaborative Robot Installations

Automation and robots are expected to have a major impact on the society in the coming years, and it has been said that about 47% of USA’s current jobs will be automated within 20 years. A study from MIT argues, however, that one should not analyse what are the professions that can be automated, but instead the tasks that can be automated within each profession. The MIT authors write that a very large proportion of all professions includes elements that can be automated and assume that the automation of the society will be slower, but that a large part of all work will be carried out in close collaboration between people and machines. A study from 2015 by the Boston Consulting Group argues for a similar development.

Humans have to some extent always worked to create solutions that can enable more efficient collaboration between people, tools and machinery in order to deliver value that is increasingly cost-effective. This work is today more important than ever for several reasons:

● Industrial customers increasingly demand that maximum value will be provided, before taking industrial business decisions.

● Competition between companies that can supply industrial value is increasing more and more, which places greater demands on optimizing the utilization of all available resources, which in turn places greater demands on effective interaction between man and machine.

● The Industry 4.0 concept puts people at the centre of industrial activity and industrial development. The concept has been of great importance for a large part of the ongoing industrial development. The view of mechanization and automation as a way to increase human capacity, and not a way to replace humans, has been a major theme in industrial thinking. Methods to ensure effective collaboration between man and machine are therefore increasingly in demand.

● It is not yet possible to cost-effectively automate all production to 100%, and working methods that can take maximum advantage of humans' and robots' respective strengths are thus of greater value to the industry.

All industrial assessment strategies must be an integral part of the above trends and they must, with ever greater clarity, continuously guarantee answers to the questions: What value do I want to deliver through the coordinated use of all available resources? And, how can I take advantage of technological advances to deliver ever more value, ever more resource efficient?

One approach to increase industrial resource efficiency is to remove barriers between robots and operators, enabling them to work in direct collaboration and take full advantage of their respective strengths, such as human abilities for adaptation and robots' speed and precision, to solve a task. Technology development within several fields such as sensors, control technology and programming has also made it ever more feasible to remove barriers from an operator safety perspective. However, even though technology development continuously makes it more feasible to remove safety barriers, robot installations without these barriers still pose hazardous working conditions for operators in several ways. In addition to possible psychological distress when working in absolute proximity with robots, there are several physical hazards such as risk for crushing, impact and puncture wounds. Furthermore, one important objective with collaborative robot installations is to reduce ergonomic problems. However, methods to verify that installations also actually reduce ergonomic problems are still required. Advanced and reliable robot control is vital to avoid physical injury, and as functions for robot control are increasingly moving to the “cloud”, this means that lacking IT-security also directly results in operator safety hazards.

Collaborative robot installations can today be found in several application areas such as service robots and industrial robots, mainly deployed for assembly tasks. This chapter focuses on industrial collaborative robots in a production system. The safety assessment strategy for collaborative robots is an attempt to give a guided tour: How to identify the areas that should be considered and developed to ensure that all types of collaboration installations can be assessed from a safety and operator acceptance perspective, as well as from a cost-effectiveness perspective. And, how to make safety assessments in different phases of the development process, such as the pre-study phase, installation phase or operational phase.

Questions concerning the interaction and collaboration between people and machines affect a wide area of knowledge and include technological and methodological, as well as psychological and physical aspects. To catch all the areas that can be processed and further developed to increase the success of safe collaborative robots is in other words a challenge in itself. The method used to identify areas to be assessed is utilization of experiences from the two ongoing Swedish collaborative robot projects: The project “Team of Man and Machine” (ToMM) and the project “A Safety Model for Collaborative Robots” (SCOR) financed by the Swedish innovation agency (Vinnova) where larger collaborative robots are studied. The analysis is based on the existing safety Machinery Directive standards1, ISO102182 and the ISO/TS 150663 that support installation of collaborative robot solutions. The analysis is also based on a selection of articles that discuss collaborative robot challenges, to a large extent based on earlier documented works resulting from the ToMM project, including a safety assessment process developed for the ToMM project [4].

DEFINITION OF A COLLABORATIVE ROBOT

The standard ISO10218 defines four types of collaborative robots:

● Safety-rated monitored stop.

● Hand-guided.

● Speed and separation monitoring.

● Power- and force-limited.

These four definitions illustrate methods to manage safety issues and potential conflicts between different types of passive and active control instructions. However, they provide limited guidance on how to divide definitions of collaborative robots into segments that can make the assessment strategy development simpler to manage. A split into different conceptual layouts, small and large collaborative robots and standard and custom-designed robots may provide better guidance.

Three main types of conceptual layouts for collaborative robot installations have been suggested [5]:

1. The robot placed inside safety fences with the workpiece placed between the robot and the operator. The collaboration is performed with the workpiece acting as a safety fence, making it possible for the operator and the robot working together on the same task.

2. The operator and the robot share the same workspace on the same side of a workpiece. Here, the ISO/TS 15066 guides on how to solve the safety issues through regulation of robot arm speed. This layout can be arranged in several ways, and sensors are demanded to control the robot arm speed.

3. The operator and the robot are working side by side, but do not work on the same workpiece at the same time. Here, the operator can either prepare for the robotic operation or vice versa. The workflow will have a character similar to a line flow instead of a collaborative task.

Large robots could be defined as the robot size required to lift and manipulate components that would otherwise require a lifting tool, or that have greater reach than humans. To optimize installations of large robots with regard to safety and productivity, it requires more analysis than to optimize installations of small robots, as the installations of the larger robots affect the need for lifting tools, the need to analyse component logistics solutions, layout design and level of automation of the installation.

Small robots could be defined as the size of the robots which is required when components are not large enough to require a lifting tool that otherwise would be needed as an alternative, and that has a range similar to a human. The boundaries as robots move from being “small” to becoming “large” are of course not distinct.

Another division can be made between standard robots and robots that have been custom-designed for collaboration. The probable difference is that the custom-designed robots have “guaranteed” technological abilities to provide adequate response to various physical control instructions from operators. Examples can be hand-guided programming capacity, sensors in the moving parts, power steering, safety design and so on. As with the boundaries for large and small robots, the boundaries of where a robot moves from being a standard robot to be custom-designed are indistinct.

ADJACENT TECHNOLOGY FIELDS

There are several technologies that are adjacent to the area of collaborative robots. Consideration of these can illustrate issues that could be seen as peripheral but which may also be of great importance for the development of safe collaborative robots, and should be mentioned.

Automatic vehicles carrying people can come in situations where they are faced with the choice whether to protect the passenger or the people that appear in front of the vehicle. It is not impossible to imagine situations where industrial installations need to be programmed to make similar choices on whom to guarantee safety.

Challenges when developing exoskeletons, telerobotics solutions, for example for medical surgeries, and some computer games have several questions in common with the development of collaborative robot installations. Such is the question of what power response should come from the machine as a response to human force.

With such divisions it may be possible to section the analyses of collaborative robots with respect to general and specific safety issues.

COLLABORATIVE ROBOTS MEAN NEW CHALLENGES

As enhanced and safe collaboration between people, tools and machines always have been sought after, it is relevant to ask what challenges are really new for collaborative robots.

Two main methods are currently used to manage safe and effective interaction between man and machine with moving parts:

● Ensuring a clear separation of different types of control instructions (such as programmed instructions to a robot or physical control instructions to, e.g., a chainsaw) so that the machines do not receive conflicting instructions.

● Ensuring clear, often physical, barriers between man and machine, such as fencing around a robot or protective equipment for chainsaw operators, supplemented by regulations and user manuals.

The need to have these barriers and distinctions of control instructions is, however, ever more reduced as technology is developing:

● Cheaper and better sensors and control technology make it increasingly possible for robots to become aware of their surroundings.

● Improved human-machine interfaces make it easier both for the operators to predict robot movements and for the robots to take on physical operator instructions.

● Better sensors and interfaces also allow for several methods of control, such as power steering and hand-guiding, voice instructions or sign instructions, combined with programmed instructions.

Taking these developments together, the need for older types of powerful barriers, for example in the form of cages for equipment with moving parts, is continuously decreasing. The possibilities to take advantage of several different types of control instructions that can be given simultaneously are increasing.

The technical challenges that can be considered new for collaborative robots can thus be said to be mainly how to design safety and control systems where there are several parallel-operating sources of control instructions and where the last safety barrier consists of the surface of the moving robot arm.

Analysis of a collaborative solution: value and optimization

In a world of increasing competition, it is becoming increasingly inadequate to focus on improving individual parameters, such as reduced need for manual hours, and use these parameters as the basis for business decisions, for example automation decisions. Demands are increasing instead of carrying out a more comprehensive overall assessment of all parameters that are affected by a business decision. This is especially important in analyses aimed at identifying whether collaboration solutions are conceivable alternative production measures, given the large number of parameters that affect/are affected by such a technical solution and the complex relationships that exist between these parameters. This makes it relevant to highlight the need for advanced means of value analysis and optimization of the layout and operation as a success factor for this type of production, where safety is an integral part of “success”. Such an approach should include a number of elements:

● The desired overarching value of an installation must be described, for example a total reduction of production costs, over an appropriate time frame, where all production costs are included, such as the cost of changing production settings, manual labour, service, upgrades and so on.

● Identification of internal connections between the changes in certain parameters, such as selection of “humane” colour and surface layer of the robot, and the impact these selections have on other parameters, such as increased acceptance by operators working in the vicinity of the robot.

● The relationship between all the inputs that affect the productivity and safety of a collaborative robot installation and the desired overall value of the installation must be identified.

● An optimization routine to find the combination of input parameters that provide the best ratio output/input must be developed.

The analysis also needs to allow for an evaluation of a collaboration solution in relation to alternative production measures. It requires both an account of all the parameters that should be considered when evaluating a standard automation decision and new/more complex influencing parameters that are relevant for collaborative installations.

Some first steps have been made in the development of such a model in the Vinnova project “Lean Automation Development” (LEAD) and the results are reported in the “Lean Automation Handbook”.

General model for safety assessment

A fundamental challenge for collaborative robot success is indeed how adequate safety can be guaranteed in a cost-effective manner. As mentioned, safety is a major challenge for several reasons: powerful barriers between man and machine cannot be utilized, the different types of injuries that can occur to various parts of the body have different pain thresholds, and safety is dependent both on the technology and on operator actions. In addition, the safety handling needs to be in accordance with existing regulations and, not the least, be cost-effective enough to enable a commercial deployment of collaborative robots as a solution to industry’s productivity challenges.

A general assessment model for dealing with safety issues for collaborative robots must therefore fulfil four conditions:

● It needs to comply with laws and industrial regulations.

● It needs to consider all safety-influencing factors and ensure the right safety for people, property and the environment.

● It needs to ensure sufficient operator acceptance.

● And, it must be sufficiently cost-effective to make interacting robots commercially interesting.

EXISTING LEGAL STANDARDS AND SAFETY ROUTINES

ISO 10218:2011 is a two-part document. Part 1, entitled “Safety of Robots”, is intended to be fully compliant with the European Machinery Directive. Part 2 on “Safety of Robot Integration” is intended to address workplace safety requirements and is directed more to the end-user than the manufacturer. In addition, new modes of operation are allowed: “synchronized” robot control, “mobile” robots mounted on automated guided vehicles (AGVs) and “assisting” robots working in a “collaborative workspace” with robot users. ISO 10218 is developed based on ANSI RIA R15.06-1999 and is a revised safety standard for industrial robots. One of the updates is on safety-rated soft axis and space-limiting, which is the enabling technology for the other collaborative robot operation. The safety-rated soft axis and space-limiting allow positive control of the robot location and thus the safety for the robot users. The case when robots and humans have to share an immersive operational space, however, is not clearly discussed in ISO 10218:2011. It suggests human-robot segregation in the workplace as the way to obtain safety. ANSI RIA R15.06-2012 is a revised version of R15.06-1999, harmonized with ISO 10218:2011. Technical Specification TS 15066 (Robots and Robotic Devices–Collaborative Robots)4specifies safety requirements for collaborative industrial robot systems and the work environment, and supplements the requirements and guidance on collaborative industrial robot operation given in ISO 10218 -1 and ISO 10218-2.

Existing robotic safety systems comprise only fixed detection zones and do not facilitate direct human-robot interaction at close distance and in immersive environment. Additional safety practices when operators are working in direct contact with robots must therefore be developed. TC 299 “Robots and robotic devices”, which was formed in June 2016, is an initiative that in the future will bundle all standardization related to industrial and service robots. Work group 3 within the TC 299 is currently working on a technical report on the safety of manual load stations, that is stations where a worker hands over a part directly to a robot end effector (e.g. a gripper)5. This will take the regulatory safety framework closer to covering all situations where operators work in direct contact with robots.

SAFETY WHEN OPERATORS WORK IN DIRECT ROBOT CONTACT

Utilization of insights from several different research areas can contribute in various ways to achieve sufficient and cost-effective safety when operators are working in direct contact with robots. Below is a list of such identified areas, to some extent recollected from an earlier work [8] including the already mentioned issues of communication through several parallel communication channels. The list includes considerations and measures that can be taken in order to make the safety assessment reasonably comprehensive, covering several types of robots, applications and the conditions that are relatively unique for collaborative robot installations.

● A picture must be created of what appropriate safety means when the operator is working in direct contact with a robot, which should include all kinds of safety issues and damages that may arise: pinching, impact, cutting and so on. Different thresholds of injury/pain/force to various parts of the body means, as mentioned, challenges for cost-effective risk assessment.

● The safety analysis should also take into account musculoskeletal disorders and ergonomics from different perspectives: the design of individual workplaces, the tasks to be performed, holistic perspective on production flow (system level) and the organization of work. If working environment conditions are not taken into account when companies are taking production effciency measures, employees can be adversely affected. Ergonomic risk factors and assessments of working conditions need to be considered. This includes focus areas such as physical exposure/load variation (physical), demands, control, communication and work organizational aspects.

● The system level that machine suppliers use when giving guarantees must be identified. Safety issues related to interfaces to supplementary technical systems that integrators use to create effective collaborative production cells must be considered.

● It must be taken into account that different robots have different technological capability to respond to operator instructions and sensor information.

● One has to deal with the fact that robots in collaborative installations must comply with at least two different, potentially conflicting sets of instructions; programmed instructions and physical, passive or active, instructions from the operator.

● One must also deal with the fact that delivery of the physical instructions from operators to robots may take place through multiple communication channels as force, voice, signs and so on. All these instructions can be conflicting and pose a potential risk factor.

● The division of roles between the robot and the operator who determines what an actor needs and must do must be designed in a way that supports safe operations. Game theory and optimization have been mentioned as ways to approach the problem.

● Models to utilize existing and future technologies to detect the position of humans and their body parts must be developed. This includes systems that give the operator an indication of a robot’s intentions and vice versa.

● Safety assessments must take into account a wide range of different applications and components to be handled by robots and operators, where some components are sharp while others may be soft.

● As more and more IT-related operations are transferred to the “cloud”, operator safety increasingly also means the same thing as IT security.

● Regardless of the theoretical high-safety level, a collaborative installation must be designed so that operators feel it is acceptable to work in the immediate vicinity of a robot.

● As the robot’s moving parts are the last safety barrier, there must be damage-minimizing solutions to handle a situation where a robot arm hits an operator, for example in the form of soft surfaces or airbags.

● Ethical considerations where the priority of the welfare of different human actors may be necessary.

FURTHER NOTES ON COST-EFFECTIVENESS

For a commercial operation, solutions for operator safety are of limited value unless this can be achieved in a cost-effective manner, that is to operate the installation in an economically competitive way. One measure to ensure this is to identify the cost-effective distribution of resources when considering a wide range of parameters that affect safety, mentioned earlier. Another measure to ensure cost-effectiveness is to integrate the safety assessment into the activities a company already is carrying out and allow the assessment to be an integral part of decision-making that must always be present before business decisions. Achieving such integral solutions should answer a number of questions to cover all steps companies commonly take before and after business decisions. How can:

● Existing overall company safety assessment strategies be supplemented so that these include assessment of collaborative robot solutions?

● The assessment be integrated in pilot studies to get a first indication of whether a collaborative installation can be a competitive solution?

● The assessment be integrated when developing requirement specifications, where the interface between the operator and collaborative robot is included?

● The assessment strategy benefit a machine supplier/Integrator need for safety assessment tools?

● The strategy take advantage of existing experience on how to ensure operator acceptance of working with powerful machines?

● The strategy be used during the installation and reconfiguration phases?

● The strategy be used during operation?

An important step when developing an assessment strategy is thus to identify how a company’s current safety practices look like and what limitations they have to also ensure effective safety assessment considerations for collaborative installations.

Empirical insights and questions in focus

The following is a deeper discussion on some selected specific challenges for collaborative robots where the solutions may be particularly important for cost-effective safety.

MAN-MACHINE COMMUNICATION

Developing effective methods for the communication between operators and robots will be critical for productivity as well as safety. One important goal for a communication solution should be to arrive at a shared understanding between operator and robot. This indicates that using the simplified definition of communication, an act to convey intended meaning from one individual or entity to another, will lead to unsatisfying results, as it does not have the perspective of shared understanding. Instead, communication should be defined as an act or process that involves several modalities, to maximize possibilities for a shared understanding.

The physical control and communication must be intuitive and easy. In the long run, this means that communication models should be developed which are able to utilize the full range of communication channels people use, which includes detection, voice, sign language, force and touch.

The human-machine voice communication field is rapidly progressing. But it has not reached such a level that it is used to any significant extent for robot communication.

Detection can be viewed as a type of communication, where the robot’s operation is affected (being stopped or slowed down) depending on detection of potentially hazardous positions of operators. Several detection systems are available. 3D vision systems, such as SafetyEye6 from Pilz, that monitor the Cartesian space around robots and stop operations in case of danger via external sensors are promising. Pilz stereovision system has been accepted for worker detection in the robotics safety area based on human-robot segregation in different zones. 3D-camera technology based on time-of-flight (TOF) measurement, such as Microsoft Kinect7 sensors, has also been tested with promising results for safety in human interaction with robots. Ultrasound detection of humans is another method that has shown promising results.

Some writers highlight sign communication as a desirable method of physical communication. As gestures are culturally bound it could be assumed that methods to compensate for this must be developed to make this communication method universally effective.

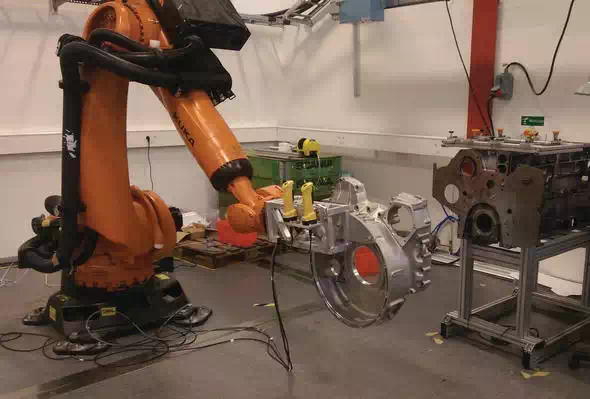

Of the physical control methods, using physical force when hand-guiding, and as a stop signal when the robot comes in contact with a human, is the most common. Hand-guiding of small robots works effectively as a programming method. But the hand-guiding of larger robots in which they are used to lift heavier components involves an element of risk, for example pinching, when the heavy component is to be mounted. The ToMM project has solved this by using an “enabling device” (handles on the gripper in the middle of Figure 1). This solution, however, reduces productivity as the operators cannot, with their hands, hold or manipulate the component the robot is holding in its grippers, and other solutions would benefit productivity. During physical collaboration where there is a direct contact between cooperating people, an important part of communication is carried out through a combination of touch and physical force. Blue Danube Robotics’ AirSkin solution is a safety sensor solution that covers the entire surface of the robot with a soft, tactile skin9. This points towards a future where efficient control and communication solutions is based on the use of smart textiles, on the robot as well as on the operator, as a communication and control tool between the operator and the robot. Smart textiles also have the potential to add more “senses” than people have, such as magnetic “senses”, gyros and ability to automatically document events. Smart textile gloves and clothing have the potential to act in several parallel tool roles simultaneously, such as sensors, actuators, safety barrier and registrars.

FIGURE 1.

Enabling device for hand-guiding, the ToMM project (handles on the gripper).

Advanced prosthetics also points towards a future of highly intuitive and flexible collaboration, where robots may be considered an “extension” of a human operator. Thought control of prosthetics has not only proved possible, but also has advanced to the level where individual fingers can be moved using thoughts only. There is limited reason to believe that this trend will not continue towards a future where all machines that require human instruction, not only prostheses, will be the subject of studies of mind control. One study from MIT and one from Brown University have already shown that an operator can give feedback to correct collaborative robot mistakes, using thoughts only.

ACCEPTANCE AND PERCEPTION

Technical system development could either be driven by technology or by human/user needs, and user-driven technical system development needs to take psychological aspects into consideration.

Technical system capacity is essential for safety as well as productivity of collaborative robot installations, but is not sufficient. If operators' perception of the robot system does not lead them to feel safe in the workplace, the adoption rate of these types of installations will be slower compared to a situation where operators feel comfortable or even enjoy being in the presence of robots. Perception and solutions for general acceptance also have wider implications as autonomous and robotic solutions reach ever more areas in the society. As mentioned, it has for example been shown that if it comes to situations where safety for a group of people only can be guaranteed for some of the people in the group, it will be challenging to decide which part to protect, as different groups of people have strong, and differing opinions regarding this decision [6].

Perception is also interlinked with cognition and culture, and how robots are perceived goes hand in hand with the understanding of robots in the society. Even though many share a fascination for robots, it is not uncommon that there is also a reluctance to accept robots. Possible job losses due to robotization and fear of possible “robot take over” as a consequence of advanced Artificial Intelligence may be reasons for low robot acceptance. In order to overcome this possible reluctance, inspiration could be found from technical solutions within the rapidly progressing social robotics field. The solutions deployed to increase the use of robotics in healthcare may also be used to influence and change the attitude to robots as something threatening.

Perception can itself be considered a form of communication, where operators' perception of the robot and the robot’s ability to interpret body language and intentions are likely to have significant relevance for productivity. For example, gaze cues have been discussed as a form of communication. A collaboration solution that has not been balanced, where the operator does not feel to be in control but is forced to wait for or is startled by the robot, will also reduce the acceptability.

There is a close relation between how individuals experience and interpret objects and what names these individuals use for the same objects. One way to increase acceptance is not using the word “robot”, but instead other words such as “assistant” or “tool”. Another is to work on the robot appearance, and use developed tools to measure the acceptability. The actual operation of the robot also affects the acceptability and it has been shown that the correlation between for example false alarms and acceptance and methods to measure the level of trust has also been developed. Further development of methods to create greater acceptance can, however, be assumed to be an important future research objective.

LAYOUT FOR PRODUCTION CELLS AND PRODUCTION LINES

Designing an efficient layout is important for all production cells. For small collaborative robots, the choice of layout is, relatively speaking, a minor challenge. An important reason for this is that small collaborative robots often can be inserted into an existing production flow for unloading of simpler assembly work.

However, experience from the ToMM project shows that optimization of the production cell layout is a significant challenge when working with large collaborative robots. There are several reasons for this. Choice of automation level and location of the transfer point between the autonomous and collaborative/hand-guided robot operation must be made. Several methods on how to carry out the transfer can also be used. Solutions that take advantage of the opportunities for effective component logistics must be developed. And, all the various alternative designs must always be evaluated with respect to safety. In the long run, safety solutions for installations with multiple interacting robots and operators in the same cell must also be developed.

Design solutions for assembly lines that is in continuous motion will mean additional challenges, which is about to be studied in an upcoming sub-project of ToMM.

An important tool is here solutions for simulation of assembly cells and assembly lines where the machines as well as human behaviour can be simulated.

SET-UP, FLEXIBILITY, PROGRAMMING AND LEARNING

Set-up time has in some cases been shown to be reduced to as little as 1 hour when small collaborative robots have been installed in existing production flows. Experience from for example the ToMM project has shown that the set-up times for large collaborative robots can be much longer, though.

Choosing an optimized and safe layout can indeed be resource demanding. Programming also requires significant resources, if the hand-guiding programming method cannot be used. This part of the installation can be even more resource-intensive than the programming for fully automated assembly cells. The reason for this is that it requires a programming block with “standard programming” for the workspace in which the robot operates autonomously, plus a programming block for the workspace in which the collaboration is carried out. Finding solutions for optimized, safe and rapid set-up is an important objective for large collaborative robot developers.

Ensuring that more productive technology is utilized in actual production when such technology is available is always important. Efficient work models for this are particularly important for collaborative robots as productivity improvements can result from at least two types of technology utilization.

One type of utilization of new technology is the introduction of more productive technology systems, for example human detection, communication, control and so on, as this new technology becomes available for practical use.

Another type of technology utilization for continuous improvement of productivity is to use learning tools. One important reason to use collaborative robot installations is that humans are better at certain things. However, recognizing this leads to the question whether robots can learn from humans working in existing collaborative installations. This is also indeed “a very active area of research”, according to Ken Goldberg, professor at the University of California, Berkeley, specializing in machine learning and robotics. It has been reported that “a Canadian start-up called Kindred AI is teaching robots how to perform difficult dexterous tasks at superhuman speeds by pairing them with human “pilots”. When a robot struggles, it asks for human help and is then controlled via VR—but the robot keeps close watch, making use of reinforcement learning to ensure that it can perform a similar task in the future”. The result of this is that robots can be taught to finish jobs using only half the time humans need for the same job. Goldberg says that “It’s at the core of what I believe is a big opportunity in robotics. There’s a huge benefit to having human demonstration”.

“Deep learning” is another learning strategy, which also has shown to improve productivity of collaborative robots.

Long-term safety vision

The foregoing sections have reasoned around different areas that are important for the commercial success of safe collaborative robots, practical experience from such installations, the future development steps that are needed and those that are to be expected. The following is a brief discussion of the possible end of the road for safety assessment strategy development. This can be relevant as a guide for long-term focus of developmental resources.

The work in today’s industrial production and other corporate activities takes place on a scale from 100% manually by human operators, to 100% automated. In all cases where operators interact with any kind of machine with moving parts, there must be some form of communication between man and machine, and some form of barrier between man and machine to minimize the risk of injury, should all communication methods fail. The vision for how this communication method and barrier should function can be said to include four main areas:

● It must enable an intuitive and frictionless interaction between robots and humans. This interaction should at least function in a similar way as when people help each other to lift and manipulate objects, and in those situations use all of the communication methods available to make the joint manipulation efficient. If one takes this to its logical conclusion, the vision is also that people should be able to communicate with robots directly from their thoughts, which earlier research in advanced prosthetics, and now also research on collaborative robots, have shown is fully possible.

● The above should also support a method for intuitive and safe distribution of roles between man and machine, including a regulatory framework for the initiatives robots can and must take, and how they should respond to human initiatives and commands.

● The solution should be able to take full advantage of opportunities to record, document and act on positions and events, for example through a well-developed regulatory framework that governs the registration, documentation and action.

● The safety shall be fully integrated into the machine to enable direct use of collaborative robots both in production and in development, without the requirement of safety assessments.

In addition, it should not be resource-demanding to identify when a collaborative robot installation is the most cost-effective solution to an industrial problem. This is of fundamental importance as technological developments make both collaborative robotic solutions and technological alternatives increasingly competitive, at the same time. Beyond the fact that the front of what can be cost-effectively automated to 100% quickly moves forward, new production techniques such as 3D printing reduce the need for bonding, assembly and so on. As shown in the European Union roadmap for precision assembly , miniaturization and increased complexity of components and equipment make manual assembly possibilities ever more difficult. This increasingly requires 100% automation. The process where more and more hardware is converted to software also reduces assembly needs.

A safety assessment strategy for collaborative robots must therefore be seen in the light of both trends that increase the possibilities to realize and utilize collaborative robots efficiently, and trends that make industrial collaborative robots less relevant. Such a strategy for collaborative robots thus must be used as a dynamic tool that continuously needs to be checked against all influencing developments. It is reasonable to assume that there are different time windows for different applications where it is relevant to focus on competitive solutions for physical interaction with the robots, which justifies a development of a safety assessment strategy. When these windows shut, it can be assumed that robot installations, or other new technology, with a 100% degree of automation become the most competitive robot solution. At the same time, one can assume that the IT development continually will open new time windows for intimate interaction between man and machine at increasingly higher cognitive levels. Possibly, or maybe hopefully, the time window for the highest cognitive level never closes.

Conclusion

Installations of collaborative robots require analysis of a wide range of issues, including the human experience perspective, to ensure safe and cost-effective operation. Below is a brief recollection of questions that could be asked when attempting to develop a comprehensive safety assessment strategy.

● How is the desired overarching production value specified and measured, and how are parameters such as installation time, product quality, work space requirements, changeover time, manual hours and so on correlated to this desired value?

● How is sufficient safety defined and measured for situations where operators and robots work in direct contact?

● How is sufficient experience of safety defined and measured for human-robot collaboration?

● To what degree is sufficient safety achieved if existing standards and regulations, applicable for collaborative robots, are followed?

● How is the full range of methods for position detection of humans and human body parts, utilized?

● How is it ensured that the full range of methods for communication between operator and robot, including potential for thought control, is utilized in an effective way?

● How are possibilities to ensure operator acceptance utilized?

● How is role setting between operator and robot handled?

● How is assembly cell layout, including automation level, component logistic and point of transfer between autonomous robot operation mode and collaborative operation mode, handled?

● Is the strategy covering all different types of injuries, applications and types of robots?

● How is it ensured that a collaborative robot safety assessment strategy is integrated in existing company safety assessment strategies?

● How is it made sure that the strategy can be used for all business-decision phases: pre-studies, installations and operation?

● How are learning strategies such as reinforcement learning and deep learning utilized for rapid improvement of safety, productivity and automation level of collaborative robot installations?

Last but not least, ongoing technology development trends simultaneously increase the opportunities for collaborative robot solutions and reduce the need for these solutions as the front line of what can be 100% automated quickly moves forward.