Introduction to Robotics

Introduction

Many definitions have been suggested for what we call a robot. The word may conjure up various levels of technological sophistication, ranging from a simple material handling device to a humanoid. The image of robots varies widely with researchers, engineers, and robot manufacturers. However, it is widely accepted that today’s robots used in industries originated in the invention of a programmed material handling device by George C. Devol. In 1954, Devol filed a U.S. patent for a new machine for part transfer, and he claimed the basic concept of teachin/playback to control the device. This scheme is now extensively used in most of today's industrial robots.

Era of Industrial Robots

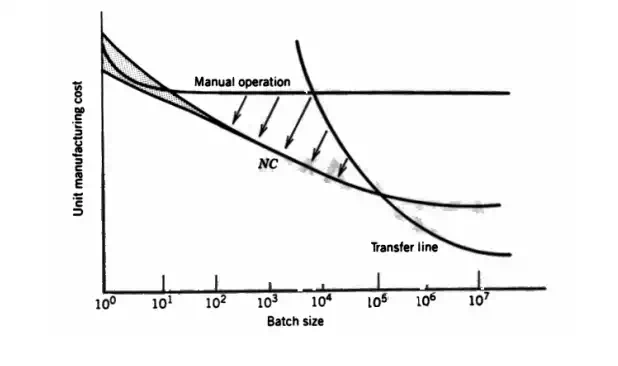

Devol's industrial robots have their origins in two preceding technologies: numerical control for machine tools, and remote manipulation. Numerical control is a scheme to generate control actions based on stored data. Stored data may include coordinate data of points to which the machine is to be moved, clock signals to start and stop operations, and logical statements for branching control sequences. The whole sequence of operations and its variations are prescribed and stored in a form of memory, so that different tasks can be performed without requiring major hardware changes. Modern manufacturing systems must produce a variety of products in small batches, rather than a large number of the same products for an extended period of time, and frequent changes of product models and production schedules require flexibility in the manufacturing system. The transfer line approach, which is most effective for mass production, is not appropriate when such flexibility is needed (Figure 1-1). When a major product change is required, a special-purpose production line becomes useless and often ends up being abandoned, despite the large capital investment it originally involved. Flexible automation has been a central issue in manufacturing innovation for a few decades, and numerical control has played a central role in increasing system flexibility. Contemporary industrial robots are programmable machines that can perform different operations by simply modifying stored data, a feature that has evolved from the application of numerical control.

General trend of manufacturing cost vs. batch size

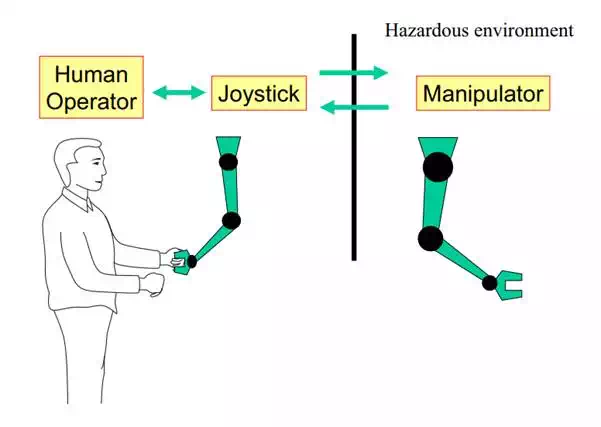

Another origin of today's industrial robot, can be found in remote manipulators. A remote manipulator is a device that performs a task at a distance. It can be used in environments that human workers cannot easily or safely access, e.g. for handling radio-active materials, or in some deep sea and space applications. The first master-slave manipulator system was developed by 1948. The concept involves an electrically powered mechanical arm installed at the operation site, and a control joystick of geometry similar to that of the mechanical arm (Figure 1-2). The joystick has position transducers at individual joints that measure the motion of the human operator as he moves the tip of the joystick. Thus, the operator's motion is transformed into electrical signals, which are transmitted to the mechanical arm and cause the same motion as the one that the human operator performed. The joystick that the operator handles is called the master manipulator, while the mechanical arm is called the slave manipulator, since its motion is ideally the replica of the operator's commanded motion. A master-slave manipulator has typically six degrees of freedom to allow the gripper to locate an object at an arbitrary position and orientation. Most joints are revolute, and the whole mechanical construction is similar to that of the human arm. This analogy with the human arm results from the need of replicating human motions. Further, this structure allows dexterous motions in a wide range of workspaces, which is desirable for operations in modern manufacturing systems.

Contemporary industrial robots retain some similarity in geometry with both the human arm and remote manipulators. Further, their basic concepts have evolved from those of numerical control and remote manipulation. Thus a widely accepted definition of today’s industrial robot is that of a numerically controlled manipulator, where the human operator and the master manipulator in the figure are replaced by a numerical controller.

Creation of Robotics

The merge of numerical control and remote manipulation created a new field of engineering, and with it a number of scientific issues in design and control which are substantially different from those of the original technologies have emerged.

Robots are required to have much higher mobility and dexterity than traditional machine tools. They must be able to work in a large reachable range, access crowded places, handle a variety of workpieces, and perform flexible tasks. The high mobility and dexterity requirements result in the unique mechanical structure of robots, which parallels the human arm structure. This structure, however, significantly departs from traditional machine design. A robot mechanical structure is basically composed of cantilevered beams, forming a sequence of arm links connected by hinged joints. Such a structure has inherently poor mechanical stiffness and accuracy, hence is not appropriate for the heavy-duty, high-precision applications required of machine tools. Further, it also implies a serial sequence of servoed joints, whose errors accumulate along the linkage. In order to exploit the high mobility and dexterity uniquely featured by the serial linkage, these difficulties must be overcome by advanced design and control techniques.

The serial linkage geometry of manipulator arms is described by complex nonlinear equations. Effective analytical tools are necessary to understand the geometric and kinematic behavior of the manipulator, globally referred to as the manipulator kinematics. This represents an important and unique area of robotics research, since research in kinematics and design has traditionally focused upon single-input mechanisms with single actuators moving at constant speeds, while robots are multi-input spatial mechanisms which require more sophisticated analytical tools.

The dynamic behavior of robot manipulators is also complex, since the dynamics of multi-input spatial linkages are highly coupled and nonlinear. The motion of each joint is significantly affected by the motions of all the other joints. The inertial load imposed at each joint varies widely depending on the configuration of the manipulator arm. Coriolis and centrifugal effects are prominent when the manipulator arm moves at high speeds. The kinematic and dynamic complexities create unique control problems that are not adequately handled by standard linear control techniques, and thus make effective control system design a critical issue in robotics.

Finally, robots are required to interact much more heavily with peripheral devices than traditional numerically-controlled machine tools. Machine tools are essentially self-contained systems that handle workpieces in well-defined locations. By contrast, the environment in which robots are used is often poorly structured, and effective means must be developed to identify the locations of the workpieces as well as to communicate to peripheral devices and other machines in a coordinated fashion. Robots are also critically different from master-slave manipulators, in that they are autonomous systems. Master-slave manipulators are essentially manually controlled systems, where the human operator takes the decisions and applies control actions. The operator interprets a given task, finds an appropriate strategy to accomplish the task, and plans the procedure of operations. He/she devises an effective way of achieving the goal on the basis of his/her experience and knowledge about the task. His/her decisions are then transferred to the slave manipulator through the joystick. The resultant motion of the slave manipulator is monitored by the operator, and necessary adjustments or modifications of control actions are provided when the resultant motion is not adequate, or when unexpected events occur during the operation. The human operator is, therefore, an essential part of the control loop. When the operator is eliminated from the control system, all the planning and control commands must be generated by the machine itself. The detailed procedure of operations must be set up in advance,

and each step of motion command must be generated and coded in an appropriate form so that the robot can interpret it and execute it accurately. Effective means to store the commands and manage the data file are also needed . Thus, programming and command generation are critical issues in robotics. In addition, the robot must be able to fully monitor its own motion. In order to adapt to disturbances and unpredictable changes in the work environment, the robot needs a variety of sensors, so as to obtain information both about the environment (using external sensors, such as cameras or touch sensors) and about itself (using internal sensors, such as joint encoders or joint torque sensors). Effective sensor-based strategies that incorporate this information require advanced control algorithms. But they also imply a detailed understanding of the task.