How to define a suitable servo motor speed

We need first to calculate the speed of load, reduction ratio value by gearbox and the horse power or KW of the motor drive capacity.

Servo motor gearbox

Every motor drive has a certain load and the motor speed is quite high for example 3000 rpm or more. We need to make reduction for the speed through choosing suitable size for the gear box since the gear box has contributed for the carried load speed. If the speed is not continued at the same level, but it is variable during variable time, we need to figure out how to solve this problem.

Servo motor gearbox

Every motor drive has a certain load and the motor speed is quite high for example 3000 rpm or more. We need to make reduction for the speed through choosing suitable size for the gear box since the gear box has contributed for the carried load speed.

If the speed is not continues in the same level, but it is variable during variable time, we need to figure out how to solve this problem.

Choosing a suitable gearbox

Reduction: most of the cases we face are reductions but there are little cases of increases. We need to know the maximum speed of load (rpm) of motor drive from the guide manual which has been provided by a motor drive manufacturer.

For example maximum allowable speed for a motor is 3000 rpm and transmission ratio is 0.1.

How to calculate maximum speed of load?

(Max speed of load)*2= (3000*0,1)

Maximum speed of load = 150

Conclusion:

If we know the maximum speed of load, we can base our choosing the motor drive and gear box size or vice versa on it.

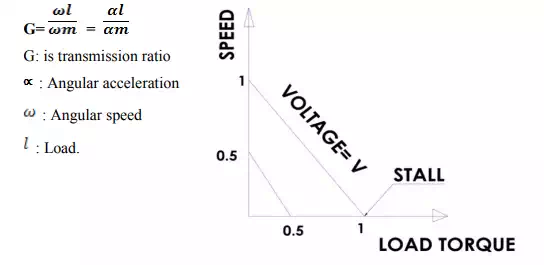

Speed and load torque diagram

Notice: The more speed, the more available torque drops, the more voltage the more speed.

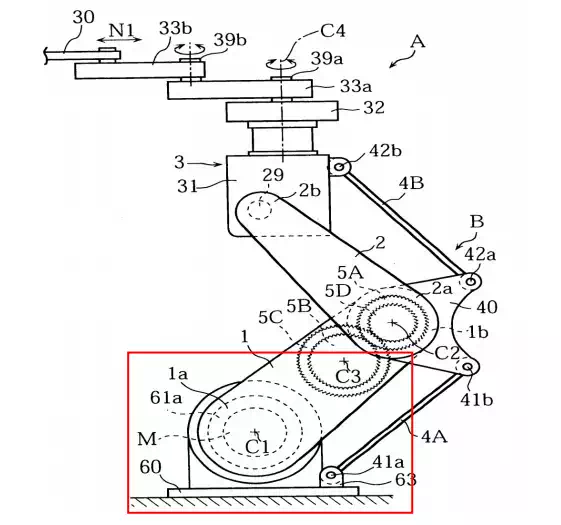

A Base servo motor example in a robot

In the below picture an arm operation mechanism for an industrial robot includes a support, a first arm, a second arm, a link base, a parallel link and a conversion mechanism. The first arm has a base end pivotally connected to the support for rotation relative to the support. The second arm has a base end pivotally connected to a tip end of the first arm for rotation relative to the first arm. The link base is pivotally connected to the first arm for rotation relative to the first arm. The parallel link keeps a constant posture of the link based upon the rotation of the first arm. The conversion mechanism converts the rotation of the link base relative to the first arm into the rotation of the second arm relative to the link base

This example shows some servo motor linkages through gears and cables