Servo Motor Design

Introduction

Servo motor is the main prime mover of the robot. This section will cover the most important of servo motor types which concerns mainly robot, servo motor behaviour in respect to torque, speed, current and voltage, and how to control the speed, type of application and how to choose the right servo motor with a suitable gearbox.

Servo motor main types

Dc servo motors are compact and light. They are two main modules permanent magnet motor (PM motors) and permanent rare earth magnets.

Servo motor

The principle is similar if we talk about DC or AC motor. A conventional motor has stator magnets, rotor wound commutator and brushes. The negative side of these models is the brushes that cause electrical sparks that creates noise and electric disturbance for other surrounding electrical devices. Then by the arrival of brushless servo motor which is faster, up to 50,000 rpm. In these modules magnets are in the rotor, coil in the stator or around it, electronic circuits features the magnetic fields and the rotor motion is sensed by hall effect sensor. These models became the most usable system because it gives more reliable operation, but they are slightly more costly.

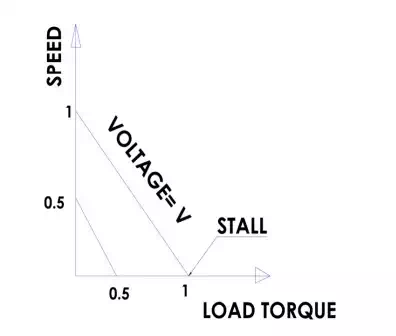

Performance characteristic of motor drive based on figure 4.2:

According to the figure 4.2 there is a stall torque point, no load speed point, there is also specific voltage, which drives the motor to no load speed and stall torque. We notice that if we heavily load the motor then the speed is zero

Behaviour of a servo motor with different speed and torque

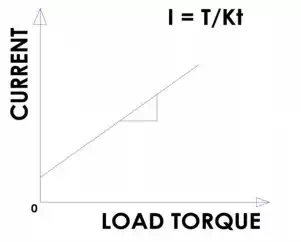

We notice from the following figure 4.3:

There is no load current Kt is the motor constant value

Load torque and current

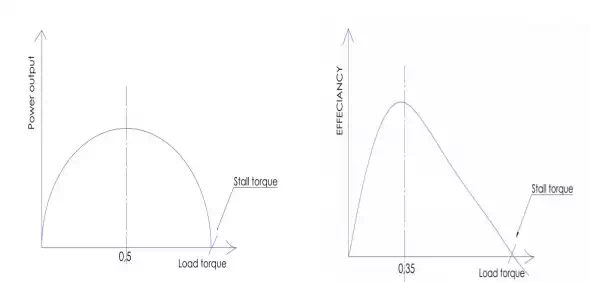

Power control of the motor: this is how the system behaves during operation.

Load torques and power output diagram Load torque and efficiency

How to select a motor in a given task:

We need to check if the motor can supply a particular torque and speed from the manufacturer user manual catalog, if electronic amplifier is able to carry the required current, if we have enough voltage to carry the load, we need to be sure that a motor does not heat up during operation time. It is easy to predict how a motor behaves beforehand because there are several formulas and curves provided by motor manufacturers, helping us to choose a suitable motor drive.

Application types in servo motor

A. Application – continues duty operation

When we drive a certain load in a particular speed or variable speed during a period of time, we need to take into consideration the load torque, speed and if electronic circuit is able to supply the required current and voltage.

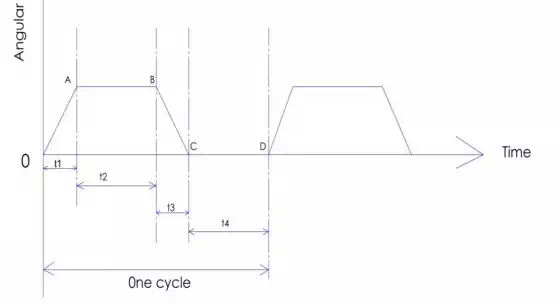

B. Application -Intermittent operation (Intermittent motion):

that has variable speed and variable periods of time, this drawing describes the motion.

Angular velocity with relative of time

We notice from the curve figure up that we have several different periods of time. From 0 to A which lasts during t1 is acceleration. From A to B which lasts during t2 is a uniform speed with 0 acceleration. From B to C which lasts during t3 is deceleration. From C to D which lasts during t4 is dwell where acceleration and velocity speed is 0.