Technologies Of A Robot

Introduction

In this chapter I will introduce robot sub systems and some parts that are used in robot structure. This section will give a brief introduction to actuators, sensors, motor drive, electronics, power supplies, algorithms and software, mechanical parts and combining methods between these parts.

Sub systems

Actuators and transmission systems they are solenoid, motor drive, pneumatic and hydraulic system which allows the robot to move. Mechanics parts are motors usually rotate and a mechanism to transfer motion to all the necessary parts of a robot to create the motion that is required. Usually robots require a power supply, this kind of supply depends on what a robot is required to do, and if it is a mobile robot then you need to decide the size of battery beside the efficiency since power supply will be in the board of robot, but if it is not mobile robot then electricity can be fed through a supply cable. Power storage system is battery or some other electronic devices. Sensors are two types Internal and external, there are many sensors in a robot which considered as the senses in a robot. Micro- controller and processors are the brain that controls the whole system. Algorithms and software are two models higher level and low level, programmer need to create software and algorithms to run the robot in a desired way.

Actuators:

Actuators are essentially the prime movers providing linear force and motion. Conventional: Pneumatics, hydraulics.

Pneumatic valve system Pneumatic Cylinder

Pneumatic and hydraulic design consideration:

With this kind of system there is input and output in the cylinder, through these input and output we pump air for pneumatic system and clean filtered oil for hydraulic system to make the piston move outside and inside to provide us with linear force and motion. You need to know in robot system how far the piston should go outside or go inside, in pneumatic system we cannot control how far the piston can go outside or inside unless you put ring in the piston rod, but in hydraulic system we can control the extension of piston by controlling the oil flow through flow control valves. Pneumatic system is used when we do not need a large force to push, but hydraulics is used when a system demands a large force, especially with big machines. The problem with hydraulic system is leakage on the other hand is not a big problem in pneumatic system since it uses air

Permanent magnet motors and stepper motors are the joint space in a robot that creates rotational motion

Servo motor

Design consideration for servo motor:

When we design a robot, we take into consideration the torque, speed and the gearbox size which should not be so heavy to the motor drive capacity. We should pay attention to the weight of motor drives and gearboxes because the base motor drive needs to carry all the motor drives and gearboxes which require quite big torque and stronger motor in the base. The selection should be harmonic, and motor should match the load. When motor rotates in a certain degree it should send feedback to the controller and to take feedback from the controller when it needs to stop rotating, this happens through an encoder which can read the degree of rotation. Nowadays these controllers are mounted in the back of the motor drive. Controller manipulates voltage and ampere to control the motor drive speed.

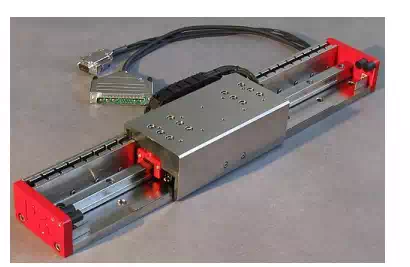

Linear motors actuators

Are used in positioning applications where high speed and accuracy are required. Main job is to produce a linear force along its length whether up and down or left and right. It has almost the same idea as hydraulics and pneumatics cylinder but the only difference that these does not use oil or air to generate force but it uses electricity .

Linear motor drive actuator

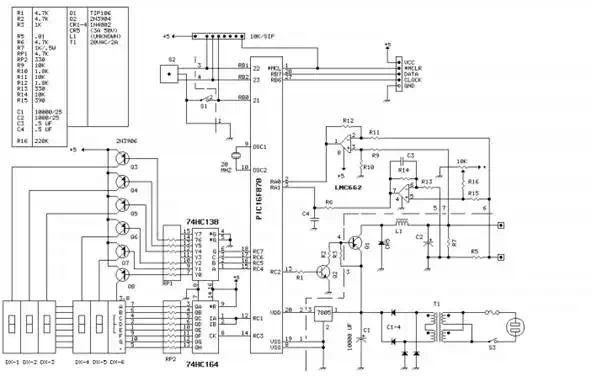

Power supplies (PWM amplifiers): is a device for increasing or decreasing the electrical power voltage and ampere. To be able to increase the velocity of the motor drive you need to increase the voltage and ampere through chart meter power supply amplifiers. It is very important to notice that the motor does not heat up because of high voltage or ampere.

Power supply circuit

Power supply circuit