Optimization of Single-Sided Lapping Kinematics Based on Statistical Analysis of Abrasive Particles Trajectories

Nowadays, products have to be manufactured with both high quality and efficiency. Finishing technologies that allow to achieve high quality surfaces with low roughness, very high accuracy of shape and dimensions are becoming increasingly important in the modern world. These results can be obtained in lapping process with the use of relatively simple means of productions. It is one of the oldest machining processes and a number of precision manufacturing applications still use the lapping process as a critical technology to achieve flatness tolerance and surface quality specification. This technology is used for machining metals and their alloys, glasses, natural materials such as marble, granite and basalt, materials used in semiconductor technology, as well as carbon, graphite, diamond and ceramics, have found use in many engineering applications. Typical parts processed by lapping are: pneumatic and hydraulic parts (valve plates, slipper plates, seals, cylinder parts, and castings), pump parts (seal faces, rotating valves, and body castings), transmission equipment (spacers, gears, shims, and clutch plates), inspection equipment (test blocks, micrometer anvils, optical flats, and surface plates), cutting tools (tool tips and slitter blades), automotive and aerospace parts (lock plates, gyro components, and seals). All of the abrasive machining are complicated and random processes with the large amount of influencing parameters and outcomes. As a result of numerous variables affecting the process quality, the main outcomes of lapping are stock removal, roughness and flatness. In order to ensure the highest quality and accuracy on worked surfaces, researches should focus on improving lapping process by studying significant process variables.

Generally, all lapping processes can be subdivided according to the active surface of the lapping tool. The lapping process where the tool axis and the workpiece surface are parallel to each other is known as peripheral lapping, and side lapping applies when the tool axis and the workpiece surface are perpendicular to each other. More specifically, the most used lapping processes can be classified as the following: according to the generated surfaces, process kinematics and tool profiles. The most well-known systems are single-sided and double-sided lapping machines. Double-side surface lapping is considered as the most accurate method in terms of parallelism and uniformity of size as two parallel even surfaces are simultaneously lapped during this process. These kinds of machine tools have a planetary system. In case of flat lapping, the standard systems with conditioning rings are mostly used.

Due to the wear, the active surface of the lapping plate has some shape errors of convexity or concavity. This has a major impact on the shape accuracy of the workpieces. If the lapping plate is out of flat, it should be re-conditioned. Kinematic method of the correction of the tool shape errors can be applied. Workpieces’ shape, size as well the lapping kinematics determine the contact between workpieces and the tool. It was observed that a trajectories distribution of abrasive particles on the lapping plate varies when the kinematic conditions are changed, e.g., by placing the workpieces at different radii, setting different rotational velocities or by introducing additional movements of conditioning ring. In this chapter, the unconventional kinematic systems were described. Carried out simulations have shown that the speed ratio k1 and the period ratio k2, which represent the relationships among the three basic motions of unconventional lapping systems, are major factors affecting trajectory distribution. The optimization of these parameters was conducted. The uniformity of tool wear was assumed as main optimization criterion.

Main factors of lapping process

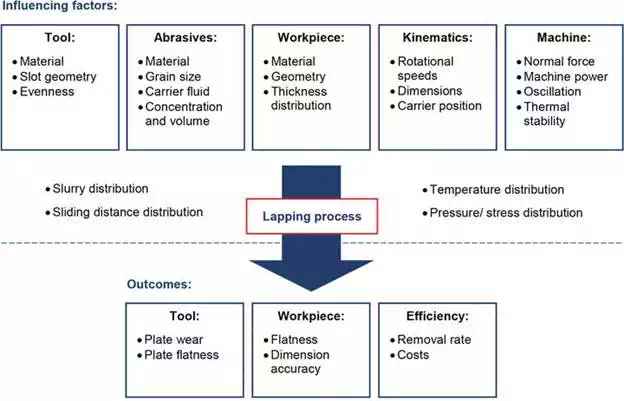

The lapping system consists of several elements: lapping plate, abrasives, lapped workpieces, kinematics and machine. They influence the lapping process which determines the product quality, tool wear and efficiency of the process. The input factors of lapping process are of two categories: controllable and non-controllable (noise) factors. The first category includes machining parameters, its working pressures and speeds, abrasive type, characteristics of the work equipment, tool, machine, duration of machining, etc. The uncontrolled input variables includes, inter alia, environmental temperature, slurry distribution, vibrations occurring in the system, internal stress, etc. An overview of main factors of lapping process is presented in Figure 1.

FIGURE 1.

Main factors of lapping process.

First of the most important input parameters, which influence the surface formation and material removal in lapping process is the lapping plate, its geometry, hardness, etc. Generally, it could be established that workpieces are machined to a mirror image of the tool with respect to the flatness. During lapping process, abrasives play an important role on material removal based on size, shape, and hardness. It has been shown that material removal rate increases with increasing abrasive size up to a critical size at which it begins to stabilize and even decrease. Moreover, multiple studies have also shown that surface roughness improves with decreasing grain size. The properties of the abrasive vehicle, which is the medium which transports the abrasive across the workpiece, are important to how effective the abrasives are in material removal. In addition, the flatness, geometric and arrangement of workpieces have also effect on lapping results. The material hardness of workpieces has a crucial influence on a removal mechanism in abrasive processes, as well on efficient of lapping. Surface formation of fragile workpieces, e.g., ceramics, occurs as a result of cracking propagation or by plastic deformation, when depth of cut is smaller than critical.

There has been a great amount of research conducted on the kinematics of lapping. The lapping pressure and lapping speed can be seen as the main variables in the lapping process. They are closely interdependent with kinematic system and machine parameters.

Abrasive wear in single-sided lapping process

One of the most important mechanisms of the lapping process is abrasive wear. The process describes the separation of material from surfaces in relative motions caused by protrusions and particles between two surfaces or fixed in one of them. In lapping process, abrasive grains are guided across the surface to be lapped and backed up by a lapping plate or conditioning rings. It is crucial to minimize friction and wear of the abrasive and to maximize abrasive wear of the workpiece.

Abrasive wear is commonly classified into two types: two- and three-body abrasion. In two-body abrasion, particles are rigidly attached to the second body. When abrasive particles are loose and free to move, then we deal with three-body abrasion. Therefore, in a two-body abrasion, the abrasive grains can cut deeply into the workpiece due to the sliding motions and in the three-body abrasion, the particles spend part of time in cutting and part of time in rolling.

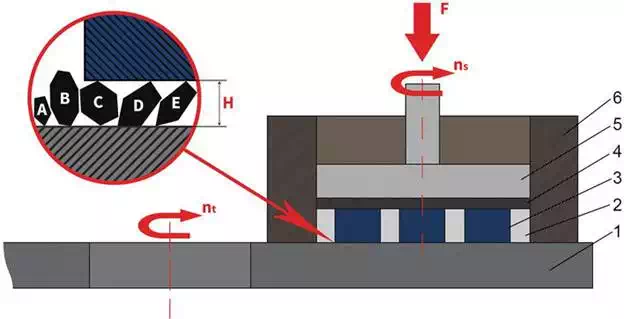

Also in the case of lapping process, several abrasives move into active positions and other grains leave the working gap. Only a specified part of all particles is able to enter the working gap with height H, which is appropriate to the lapping pressure F. Figure 2 presents abrasive wear in single-sided lapping process and different types of lapping grains being in the working gap between tool and workpieces. As can be seen in Figure 2, abrasives play a crucial role on material removal based on size, shape, and hardness. For example, it can be noticed that grain A is too small and grain B is too big. It means that only some of the abrasives are active and they roll like grain C or slide like grain D. The example of passive grain is grain E, which does not stick to the affecting partner.

FIGURE 2.

Single-sided lapping process: (1) lapping plate, (2) separator, (3) workpiece, (4) felt pad, (5) weight system, (6) conditioning ring.

Moreover, regular sliding grains in and out of the working gap cause the changes in the initial structure of the lapping plate. First, strongest loaded grains disintegrate into smaller and their particles are able to take part in the lapping process depending on the size and shape. Hence, the number of bigger grains is reduced, while the number of smaller grains is increased and the structure of the lapping tool is changed. The changing trajectories and velocity of abrasives cause some grains crash with each other or with grain fragments. It can be established that after crashes, grains are accumulating and can disintegrate at any time. The chain between a workpiece and lapping plate is fulfilled by active grains, which under their impact and edge transfer the normal forces into the surface of the affecting partner. Acting forces are proportional to the material volume. To reach a stationary working gap height, the amount of all normal forces transferred by active grains must be equal to the pressing force F [3].

Kinematic analysis of standard single-side lapping system

SINGLE-SIDED LAPPING MACHINE OVERVIEW

Nowadays, there are many manufacturers that offer surface planarization technology with lapping kinematics. The most well-known are Peter Wolters, Lapmaster, Stähli, Engis, Hamai, Kemet, Mitsunaga and LamPlan. After a careful analysis of numerous researches and offers of many lapping machines producers, it has been emerged that most of lapping machines have standard kinematic system. Single-sided lapping machines differ in tool size, diameter of lapping plate, size and number of conditioning rings, type of pressure system (weighting or pneumatic system). More complex machines are equipped with forced drive option of conditioning rings. Such a system maintains a constant speed of workpieces.

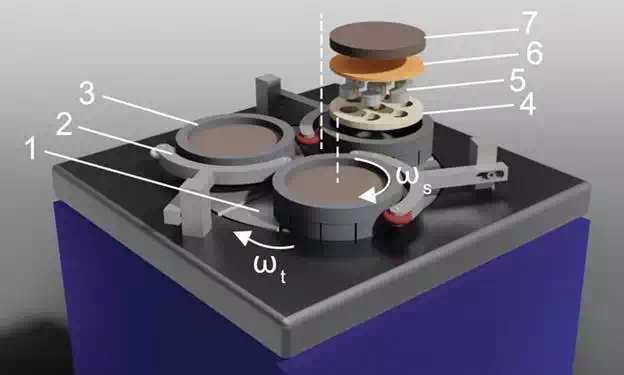

Conventional single-sided lapping machine is shown in Figure 3. The key component of the machine is the tool, i.e., the annular-shaped lapping plate (1), on which the workpieces (3) are applied to. One machine usually has three to four conditioning rings (5). However, laboratory lapping machines that have one ring are also popular. The lapping plate (1) rotates with angular velocity ωt and it drives conditioning rings, where separators (4) are placed allowing additional move of workpieces (3). Due to the frictional force, conditioning rings (5) rotate on the working surface of lapping plate (1) with angular velocity ωs. This force depends on a radial position, velocity of conditioning rings, and friction conditions. The radial position (R) of conditioning rings can be controlled with roller forks (2). During the lapping process, a certain load is provided through felt pad (6) by weight disk (7) or pneumatic system. In this way, the parts are pressed against a film of abrasive slurry that is continuously supplied to the rotating lapping plate.

FIGURE 3.

Single-sided lapping machine: (1) lapping plate, (2) roller forks, (3) conditioning ring, (4) separator, (5) workpieces, (6) pad, (7) weight.

KINEMATICAL FUNDAMENTALS

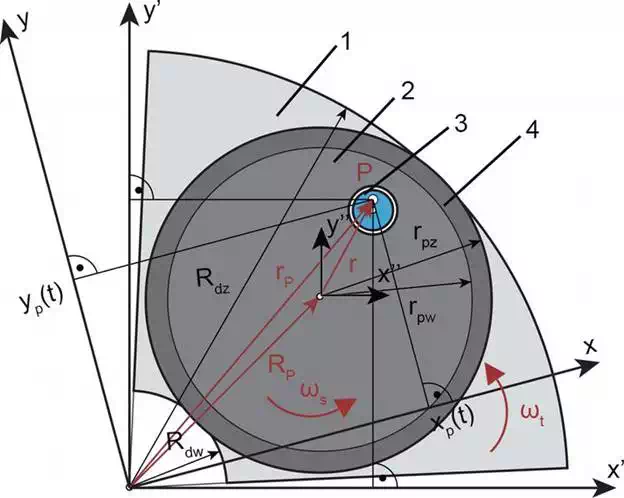

Due to the fact that the kinematics of the lapping is affected by a number of factors related to the influence and properties of the workpiece—abrasive slurry—lapping plate system, in the following model considerations, it is assumed that the angular velocities of conditioning rings, separator and workpieces are identical. Moreover, conditioning rings role is to even the lapping plate (Figure 4).

FIGURE 4.

Kinematic diagram of single-sided lapping machine: (1) lapping plate, (2) separator, (3) workpiece, (4) conditioning ring.

The input parameters for analysis are: angular velocity of lapping plate ωt and of conditioning rings ωs, inner Rdw and outer Rdz diameter of lapping plate, radial position of conditioning ring Rp.

In order to model a lapping plate, the position of any point P belonging to a workpiece must be determined. It is possible to do this by a radius vector in two coordinate systems: absolute and relative, which is related with rotating tool. The position of any point P(r,ϕp) belonging to a workpiece in single-sided lapping system are determined in x″y″ coordinate system, which is related to conditioning ring as:

The coordinates of point P in x′y′ coordinate system are:

![]()

![]()

![]()

![]()

After transforming it to coordinate system related to rotating lapping plate:

![]()

![]()

![]()

The relative velocity v of point P is defined as the derivative of the position with respect to time:

![]()

SINGLE ABRASIVE TRAJECTORIES ANALYSIS

Equations of any point belonging to a workpiece position in standard single-sided lapping system were implemented in MATLAB program. This program allows to analyze single-side lapping system and can be used to mark out cycloids paths, which can be treated as areas where the lapping plate wears by the grain placed in a specific location of a conditioning ring or workpiece.

In order to analyze single abrasive trajectories, an additional parameter must be defined, which is rotational speed ratio of the conditioning ring to the lapping plate:

![]()

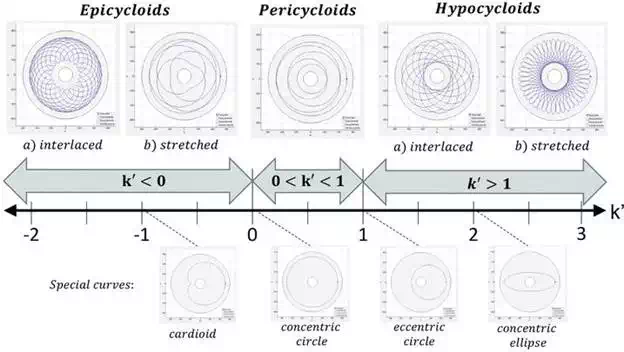

Analysis of multiple simulations leads to conclusions that the k1 parameter determines the type of cycloid path. Results are shown in Figure 5. It can be observed that epicycloid trajectories are marked out when the value k1 is less than 0. When the value k1 is close to 0, stretched epicycloid then interlaced epicycloid are received. Pericycloids appear when the value k1 is between 0 and 1. At k1 bigger than 1, hypocycloids can be obtained. Initially, they are stretched hypocycloids; then, they transform to interlaced hypocycloids. Attention needs to be paid to the following trajectories: cardioid (k1 = −1), concentric circle (k1 = 0), eccentric circle (k1 = 1) and concentric ellipse (k1 = 2). Moreover, the cycloid curvature radius RP(t) is a periodic function of time t and its cycle equals:

![]()

FIGURE 5.

Path types depending on the rotational speed ratio k1.

Unconventional lapping kinematics systems

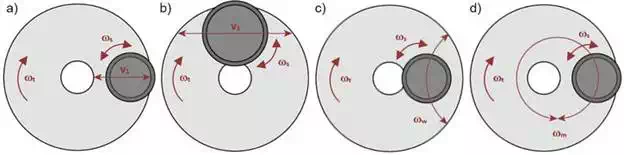

Analysis of numerous researches and offers of many lapping machines producers leads to conclusion that most of lapping machines have the standard kinematic system. Unconventional lapping systems, where the conditioning ring performs an additional move such as radial, secant, swinging or off-center are presented in Figure 6. Simulations have shown that changing the kinematic system in single-sided lapping process causes a wide density variation of single abrasive trajectories.

FIGURE 6.

Examples of approach to kinematics system lapping plate—conditioning ring: (a) radial, (b) secant, (c) swinging, and (d) off-set.

The simulations allowed state that the most desirable system is that system, which allows to smoothly control the position of the conditioning ring on the lapping plate. It was pointed out that some systems are not very different from the standard kinematic system. Generated trajectories were almost identical. This is due to the fact that with such systems, the deflection of conditioning ring along the radius was much smaller, than in the case, for example, of the radial lapping system. In order to correct the flatness of lapping plate, the ring must be shifted toward or out of the center of the tool.

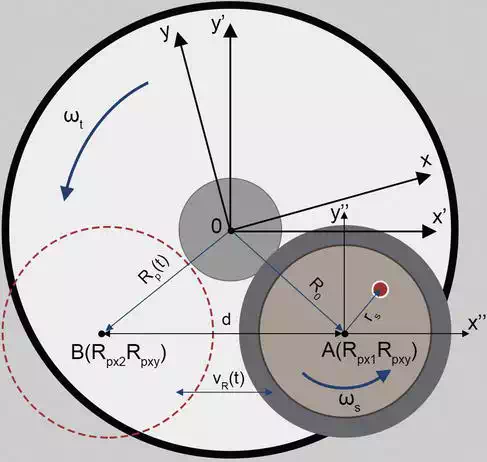

The detailed kinematic diagram of single-sided lapping system with the additional movement of conditioning ring along a chord is presented in Figure 7. It can be observed that in this idea, there is only one conditioning ring, which in addition to rotary motion performs a reciprocating motion between point A and B. The position of the conditioning ring is not constant as in conventional system, parameter RPx(t) changes the value in time. The distance from the center of the lapping plate to the chord equals RPy.

FIGURE 7.

Diagram of single-sided lapping machine with reciprocating movement of conditioning ring.

The principle of kinematics calculation is identical as in case of standard single-sided lapping system. Due to additional motion of the conditioning ring, only Eq. (3) must be changed:

![]()

Considering the reciprocating motion of the conditioning ring, RPx is a function of time and it can be expressed as:

![]()

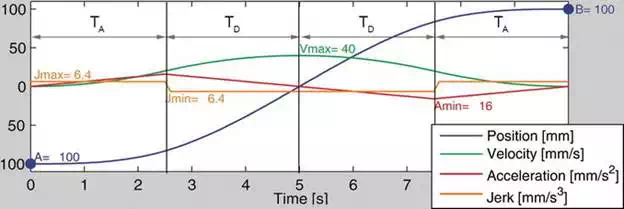

There are many ways in positioning control applications to move from one point to another. The most common are trapezoidal and S-curve motions. In trapezoidal move profile, velocity is changed linearly and acceleration makes abrupt changes [14]. This can be quantified in an S-curve motion profile by “jerk,” which is the time derivative of acceleration. S-curve motion helps to smoothen the motion and reduce the possibility of exciting a vibration or oscillation [15]. A single stroke of reciprocating motion with S-curve profile is shown in Figure 8. The conditioning ring moves between two points, where TRis the reciprocating period, TA is the acceleration time of the uniformly accelerated motion and TD is the deceleration time of the uniformly decelerated motion. The conditioning ring has a maximum velocity vRmax at the central range of the reciprocating stroke and uniformly accelerated and decelerated motions at the two ends of the stroke.

FIGURE 8.

Single stroke of reciprocating motion with S-curve profile.

For the simplicity, the velocity expressions of another non-dimensional parameter was introduced and defined by Eq. (12). Parameter k2 is the ratio of the reciprocating period to the lapping plate rotary motion period:

![]()

where d is the reciprocating stroke, TR and TT are the periods of the reciprocating motion of the conditioning ring and rotary motion of the lapping plate.

Kinematic optimization

Kinematic analysis showed that the basic kinematic parameters significantly affect the trajectory and velocity distributions. To improve the quality and flatness of the machined surfaces, the selection of parameter values, which are optimal was carried out. It was assumed that, the main optimization criterion is the uniformity of tool wear. In this section, the material removal rate and the lapping plate wear model are described in detail. Based on the lapping plate wear, its uniformity is calculated and the maximum value is sought.

MATERIAL REMOVAL RATE

The volume of material removed by lapping process at a local position during every unit of time is an important part of study about lapping process. There are many models which describe material removal rate (MRR) during lapping, grinding or polishing. Several researchers worked on experiment and analytical models. They show that the lapping process can be improved by optimizing both the machining efficiencies, and the consideration of the process parameter influences with surface lap height. Considerations about MRR are important because it is the only solution to provide the maintenance of reliability and lifetime of the produced workpieces.

One of the most common wear models in abrasives process is the tribological model developed by Preston, who related relative velocity and pressure to material removal rate (MRR) which is known as Preston’s equation:

![]()

where H is a height of removed material in any point on the lapping plate, k is a constant relating to the process parameters, p is the applied pressure, and v is the relative velocity of the workpiece. The parameter k varies based on any modifications to the material removal process such as abrasive and slurry type, feed rate, and other process parameters.

However, some of the experiments have shown that in the case of relatively high or low velocities and pressure, linear relationship in Preston’s equation does not hold true. Therefore, many modifications to the Preston’s equation were proposed. Moreover, there are many formulations in literatures, which are based on the Preston’s equation. Using the Preston’s equation, Runnels and Eyman proved that the MRR in the chemical-mechanical polishing process is related to the normal and shear stresses. Tseng and Wang modified the Preston’s equation to express the MRR as a function of the normal stress of the wafer, the relative velocity of the polishing and the elastic deformation of the abrasive grains. Nanz provided new MRR equation considers the bending of pad and flow of slurry.

LAPPING PLATE WEAR MODEL

Intensity of lapping plate wear can be assumed as a contact intensity of the tool with the workpieces through the lapping abrasive grains. There are different methods for calculating contact intensity. This section assumes the method of calculating particles density of interpolated trajectories. Therefore, in order to simulate the trajectories and to count their distribution, Matlab program was designed.

An example of trajectories density determination steps is shown in Figure 9. Initially, location of random particles is generated within the conditioning ring. Then, the trajectories of the particles are calculated with a use of kinematic equations. A set of points, which are equally spaced from each other, are generated with interpolation function. The lapping plate surface is divided into small squares with the same area. Finally, a statistics function is used to count the total number of points within each square of the lapping plate surface. The contact intensity can be developed for a profile of the tool. It allows to determine if the wear causes a concavity or the convexity. The area of the lapping plate must be divided into equal rings. A measure of points in an appropriate area is determined by equation:

![]()

where n is a points number in area Ai and r is rings width.

FIGURE 9.

Trajectories density determination: (a) random generated particles, (b, c) trajectories generating, (d) trajectories interpolation, (e) density of trajectories, (f) profile density of trajectories.

To calculate the standard deviation SD of all the values of Di, which is given by:

where D¯ represents the average of all the values and N is the total number of the divided rings or squares.

PARAMETERS OPTIMIZATION

Trajectories distribution of particles in single-sided lapping process is significantly affected by rotational speed ratio of the conditioning ring to the lapping plate k1 (Eq. (9)) in standard single-sided lapping system and in addition by period ratio of the reciprocating motion of the conditioning ring to rotary motion of the lapping plate k2 (Eq. (13)) in system with additional movement of conditioning ring. To obtain a better uniformity base on trajectory simulations and consequently even lapping plate wear, it is important to optimize both parameters. The uniformity of tool wear was assumed as main optimization criterion. In order to describe the evenness of the lapping wear, the trajectories distribution uniformity is defined:

![]()

where SD is the standard deviation of trajectories density and D¯ is the average value of the trajectories distribution.

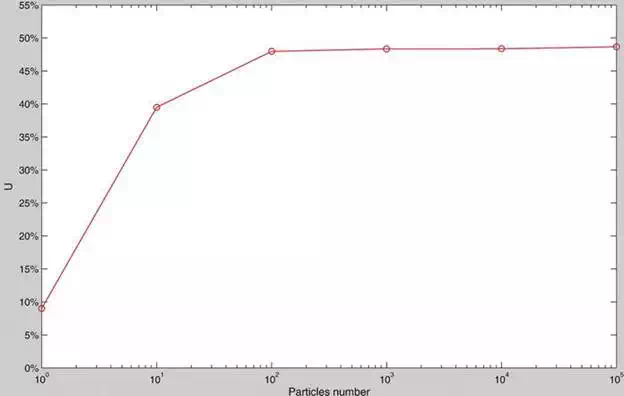

It can be predicted that during the lapping process, there are more than 1 million active particles in the slurry and on the lapping plate. However, because of the calculation time, an appropriate particle number which can reflect the same regularity as the real number has to be determined. Figure 10 shows the influence of the amount of abrasive grains to the uniformity. Results are presented for standard single-sided lapping system, when k1 = 0.45 and RP = 125 mm. It can be observed that for 1000 randomly distributed particles, uniformity is stable and constant.

FIGURE 10.

Uniformity of trajectories distribution produced by different number of random particles.

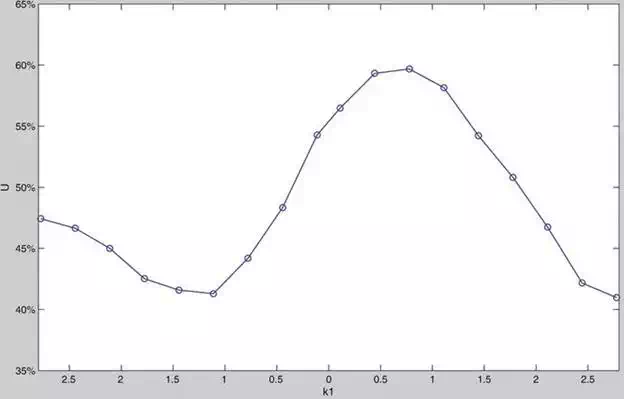

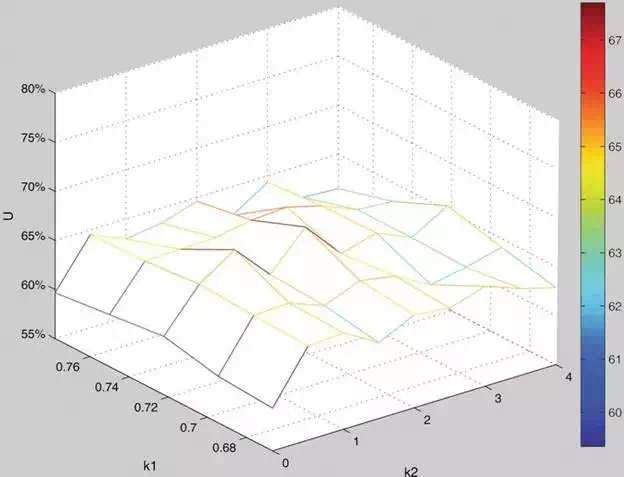

Trajectory density uniformity for standard single-sided lapping system and for single-sided lapping system with reciprocating motion of conditioning ring is presented in Figures 11 and 12. Trajectories were generated during 60 s on lapping plate with internal diameter of 88 mm and outer diameter of 350 mm. The maximum uniformity was obtained in conventional system, when k1 = 0.6–0.9, and in non-standard lapping system, when k1 = 0.65–0.75 and k2 = 1–2. For single-sided lapping system with reciprocating motion of conditioning ring, the uniformity was about 10% higher.

FIGURE 11.

Trajectory density uniformity versus k1 for standard single-sided lapping system, 1000 random particles, radial position of conditioning R = 125 mm, simulation time t = 60 s.

FIGURE 12.

Trajectory density uniformity versus k1 and k2 for single-sided lapping system with reciprocating motion of conditioning ring, 1000 random particles, simulation time t = 60 s.

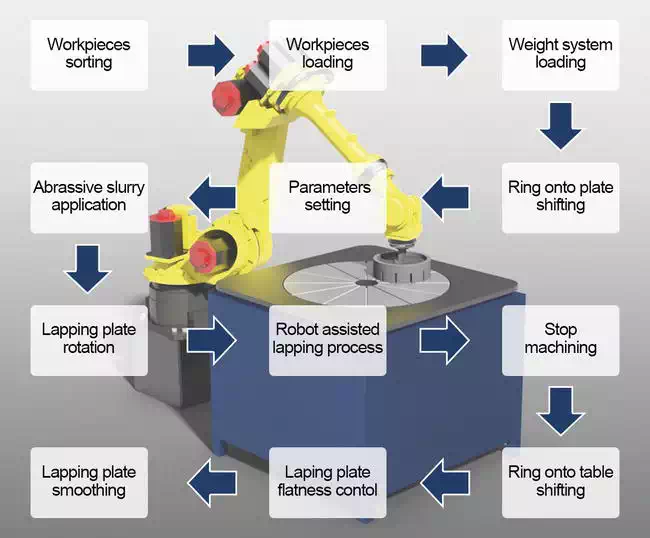

Automated lapping system

The above considerations regarding complex kinematics of lapping process were the starting point to develop automated lapping system. Nowadays, machine tools are more efficient than in the past. Lapping machine manufacturers also improve their machines and supply their basic constructions with additional components. As a result of automation, some of the supporting operations can be eliminated. Lapping machines are supplied with feeding tables, loading and unloading systems of conditioning rings, which form mini-production lines. However, it was emerged that the system where the ring is led by the manipulator during the machining is novel. In order to create universal mechanism that moves the conditioning ring at any path is complicated and in some cases impossible. Thanks to the robot that moves an effector from point to point, it is possible to change the ring trajectory at any moment and different conditions. Owing to this solution, it is possible to apply any lapping kinematics and use robot for supporting operations.

One of a number of challenges in designing automated manufacturing systems is the selection of a suitable robot. This problem has become more demanding due to increasing specifications and complexity of the robots. However, it was decided that the robot should perform material handling tasks and also lapping process. In initial selection, the articulated robots, which have four to five degrees of freedom and are powered by an electrical drive should be chosen for further evaluation. Furthermore, a continuous path or Point-to-Point control system is required.

The idea of how single-sided lapping machine and the robot working together presents Figure 13. The robot situated next to the lapping machine handle primarily sorted workpieces from the table to the separator, located in conditioning ring. Then robot grips the conditioning ring and shifts it onto the lapping plate, which starts to rotate. The machining is executed by the robot. It shifts the ring with workpieces in such a way to keep the flatness of the plate along the radius. After lapping process, robot shifts the conditioning ring onto collecting table and workpieces fall into the box with finished parts. Finally, the flatness of the lapping plate is controlled and is fixed in case when an error occurs.

FIGURE 13.

Idea of robotic single-sided lapping system.

Conclusions

The aim of this chapter was to present the influence of selected factors on the geometrical results of the single-sided lapping process. One of the most crucial factors is kinematics of the executive system. Since flatness of an active surface of the lapping plate has an essential influence on the shape accuracy of lapped surfaces, the key is to maintain the flatness of the tool. It can be established that lapping plate flatness deviation can be caused by its uneven wear.

A desired distribution of the contact density, which determines a wear and allows to correct the flatness error of the lapping plate, can be obtained by choosing appropriate kinematic parameters. Therefore, the kinematic model of single-sided system was in detail analyzed and modeled in Matlab program. Based on the simulations, it was observed that a trajectories distribution of abrasive particles on the lapping plate varies when the kinematic conditions are changed, e.g., by placing the workpieces at different radii, setting different rotational velocities or by introducing additional movements of conditioning ring. Hence, the influence of additional guiding movements of the conditioning ring has been verified. Major factors affecting trajectory distribution are the speed ratio k1 and the period ratio k2, which represent the relationships among the three basic motions of unconventional lapping systems. The optimization of these parameters was aimed at improving the quality and flatness of the machined surfaces. Main optimization criterion was the uniformity of tool wear. The maximum uniformity was obtained in conventional system, when k1 = 0.6–0.9, and in non-standard lapping system, when k1 = 0.65–0.75 and k2 = 1–2. For single-sided lapping system with reciprocating motion of conditioning ring, the uniformity was about 10% higher than in conventional system.

|

ωt |

angular velocity of the lapping plate |

|

ωs |

angular velocity of the conditioning rings |

|

Rdw |

inner diameter of lapping plate |

|

Rdz |

outer diameter of lapping plate |

|

Rp |

radial position of conditioning ring |

|

rP, rS |

radial position of examined points |

|

t |

machining time |

|

H |

wear removal rate |

|

k |

Preston’s coefficient |

|

p |

force per unit area |

|

v |

lapping relative velocity |

|

Di |

trajectories density |

|

d |

distance of reciprocating motion |

|

vR |

linear velocity of reciprocating motion |

|

TR |

reciprocating period |

|

TA |

acceleration time |

|

TD |

deceleration time |

|

JA |

acceleration jerk |

|

JD |

deceleration jerk |

|

k1 |

rotational speed ratio of the conditioning ring to the lapping plate |

|

k2 |

period ratio of the reciprocating motion of the conditioning ring to rotary motion of the lapping plate |

|

SD |

standard deviation |

|

U |

uniformity of lapping plate wear

|