Kinematic Model for Project Scheduling with Constrained Resources Under Uncertainties

Project scheduling problems have been well studied in the literature since the 1950s. According to Ref., project scheduling is an important process in project management. The project scheduling literature largely concentrates on the generation of a precedence-feasible and resource-feasible schedule that optimizes scheduling objective(s) (most often the project duration) and that serves as a baseline schedule for executing the project. Baseline schedules serve as a basis on which to allocate resources to different activities in order to optimize some measure of performance and for planning external activities such as material procurement, preventive maintenance and delivery of orders to external or internal customers.

However, project scheduling is a difficult process due to scarce resources as well as precedence relations between activities. Admissible schedules must obey constraints such as precedence relations (a task cannot start unless some other tasks have been completed) and resource restrictions (labour and machines are examples of scarce resources with limited capacities). Thus, the resource-constrained project scheduling problem (RCPSP) consists of project activities subject to many kinds of uncertainties that must be scheduled in accordance with precedence and resource (renewable, non-renewable and doubly constrained) availabilities such that the total duration or makespan of a project is minimized.

Most of the variants and extensions of the RCPSP may be summarized and classified within multiple modes, generalized time lags and objective functions, resulting in highly complex optimization problems. The RCPSP has become a well-known standard problem in the context of project scheduling, and numerous researchers have developed both exact and heuristic scheduling procedures. Due to the complex nature of the problem, only a small number of exact algorithms have been presented in the literature, and many heuristic solution algorithms have been presented in the literature.

Therefore, this chapter presents the development and implementation of the kinematic model named as Coupled Estimate Technique for project scheduling with constrained resources under uncertainties. In the Coupled Estimate Technique, the modelled duration depends on the planned duration and on the resource variability (aleatory uncertainty), and the modelled resource depends on the planned resource and on the duration variability (aleatory uncertainty).

TAILORING OF THE ROBOTIC MANIPULATOR KINEMATIC CONCEPTS TO THE COUPLED ESTIMATE TECHNIQUE

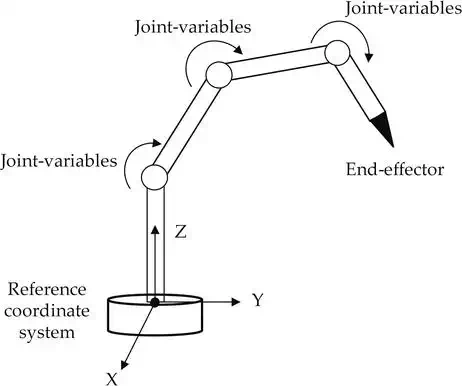

The development of the Coupled Estimate Technique was based on robotic manipulator kinematic concepts. Kinematics is the science of motion that treats motion without regard to the forces/moments that cause the motion. Robotic manipulator or industrial robot consists of several rigid links connected in series (open kinematic chain) by revolute or prismatic joints; one end of the chain is attached to a supporting base, while the other end is free and equipped with a tool (end-effector) to manipulate objects or perform assembly tasks; and the end-effector could be a gripper, a welding torch, an electromagnet or another device.

Robotic manipulator kinematics deals with the analytical description of the spatial displacement of the end-effector with respect to a fixed reference coordinate system, in particular the relations between the joint variables and the position and orientation of the end-effector. There are two (direct and inverse) fundamental problems in robotic manipulator kinematics. Given a set of joint variables, the direct kinematic problem is performed to find the position and orientation of the end-effector relative to the fixed reference coordinate system. Given the position and orientation of the end-effector relative to the fixed reference coordinate system, the inverse kinematic problem is performed to find all possible sets of joint variables that could be used to attain this given position and orientation. Figure 1 illustrates a robotic manipulator or industrial robot.

FIGURE 1.

Robotic manipulator or industrial robot.

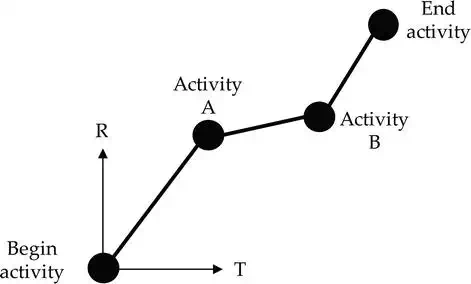

In analogous way, the Coupled Estimate Technique deals with the analytical study of the geometry of project activities of a precedence diagram with respect to a fixed reference two-dimensional coordinate system (0, T, R) where the abscissa is the duration axis (T) and the ordinate is the resource axis (R). Thus, the precedence diagram may be considered as a kinematic chain (open, closed and/or hybrid), where one end of the chain is attached to a fixed reference two-dimensional coordinate system and represents the begin project activity, while the other end is free and represents the end project activity, as well as the rigid links represent the precedences between project activities and joints are represented by the project activities. Figure 2 presents a precedence diagram analogous to a robotic manipulator in open kinematic chain.

FIGURE 2.

Precedence diagram in open kinematic chain.

THE MAIN EFFECTS OF THE UNCERTAINTIES IN PROJECT SCHEDULING

The majority of research efforts related to RCPSP assume complete information about the scheduling problem to be solved and a static and deterministic environment within which the precomputed baseline schedule is executed. However, in the real world, project activities are subject to considerable uncertainties, stemming from various sources, which are gradually resolved during project execution.

The presence of uncertainties in project management is recognized by practitioners and researchers as an important cause underlying the high project failure rate. Project-related uncertainties can lead to numerous schedule disruptions. These uncertainties may stem from the following sources: activities may take more or less time than originally estimated; resources may become unavailable; material may arrive behind schedule; ready times and due dates may have to be changed; new activities may have to be incorporated; activities may have to be dropped due to changes in the project scope; and weather conditions may cause severe delays.

This chapter makes a distinction between uncertainty and risk, assuming that there are degrees of knowledge about the estimations of project duration and resources; the uncertainty may be quantifiable but without probability of occurrence, while the risk is quantifiable and with probability of occurrence. Uncertainty may be aleatory due to the intrinsic variability of projects or epistemic due to the lack of relevant knowledge related to carrying out the project. Thus, quantifying uncertainty is relevant to project scheduling because it sheds light on the knowledge gaps and ambiguities that affect the ability to understand the consequences of uncertainties in project objectives.

COMMON APPROACHES FOR RCPSP UNDER UNCERTAINTIES

From a modelling viewpoint, there are four approaches for dealing with uncertainty quantification in a scheduling environment where the evolution structure of the precedence network is deterministic: reactive scheduling, stochastic scheduling, scheduling under fuzziness and proactive (robust) scheduling.

The reactive (predictive) scheduling models do not try to cope with uncertainty quantification when creating the baseline schedule. Basically, efforts are largely concentrated on repairing, revising or re-optimizing the baseline schedule when an unexpected event occurs.

The reactive effort may be based on very simple techniques aimed at a quick schedule restoration; a typical example is the well-known right-shift rule. This rule will move forward in time all the activities that are affected by the delays; often, the precedence diagram must be tailored in order to rearrange the changed activities. The reactive effort also may be based on as full rescheduling of the precedence diagram.

Most of the literature on the RCPSP assumes that activity durations are deterministic; however, activity durations are often uncertain. These uncertainties may be due to different sources, such as estimation errors, late delivery of resources, unforeseen weather conditions, unpredictable incidents (machine or worker) and others.

The stochastic RCPSP acknowledges that activity durations are not deterministic, i.e. the activity durations are modelled as stochastic variables. Therefore, the stochastic RCPSP aims to schedule project activities with uncertainty quantification of durations in order to minimize the expected project duration subject to precedence and constrained resources. The stochastic project scheduling models view the project scheduling problem as a multistage decision process; the complete schedule (containing all activities) is constructed gradually as time progresses by means of a scheduling policy, exploiting the available information about the uncertainty of activity durations.

Generally, the uncertainty of activity duration in project scheduling was handled by stochastic approaches using a probabilistic-based method. This kind of uncertainty in project duration is associated with randomness. However, for projects never be carried out previously, it is infeasible to determine the probability distribution of activity duration.

Therefore, the fuzzy project scheduling approach is used when the probability distributions for the activity durations are unknown due to a lack of historical data and, thus, the activity durations have to be estimated by human experts. In the situations involving the imprecision instead of uncertainty, the project scheduling literature recommends the use of fuzzy numbers for modelling activity durations. Instead of probability distributions, these quantities make use of membership functions, based on possibility theory.

Traditionally, the robust schedule may absorb some level of unexpected events (machine breakdowns, staffing problems, unexpected arrival of new orders, early or late arrival of raw material and uncertainties in the duration of processing times). Thus, in order to minimize the impacts of uncertainties and the need of new scheduling or rescheduling, proactive scheduling approach aims at the generation of a robust baseline schedule that incorporates a certain degree of anticipation of potential variability or of potential disruptions according to the objective values (makespan).

The proactive (robust) project scheduling model has prospered widely in the field of machine scheduling. Redundancy-based techniques related to durations and resources have already found their way to the field of project scheduling. The critical chain project management (CCPM) and Success Driven Project Management (SDPM) methods are becoming increasingly popular among project management practitioners.

MAIN DIFFERENCES BETWEEN THE COUPLED ESTIMATE TECHNIQUE AND THE COMMON APPROACHES FOR RCPSP UNDER UNCERTAINTIES

This chapter presents a kinematic model named as Coupled Estimate Technique for project scheduling with constrained resources under uncertainties. This technique considers precedence, duration, resources and uncertainties related to project activities in order to analytically model the outcomes of project-related events or conditions (uncertainty) with the potential of favourable but mainly adverse consequences on project objectives (duration and resources). This approach can be used to quantify uncertainties; thus, it can help to solve project scheduling problems related to the following limitations and disadvantages identified in the literature review:

● The literature on project scheduling under risk and uncertainty was clearly conceived in a machine scheduling environment, whereas this work presents a project scheduling model from the viewpoint of project management.

● Projects are often subject to considerable uncertainty during their execution, but most of the research on project scheduling deals with only one source of uncertainty most often the duration of activities. With the kinematic model detailed herein, the project activities have a set of attributes represented by the duration and resources as well as the uncertainties related to duration and resources.

● Traditional project scheduling is represented mainly by an activity-on-node network. However, this representation is insufficient and inadequate when the activities of a project have a set of attributes. In the kinematic model, project scheduling is represented by IDEF0 (Integrated Computer-Aided Manufacturing Definition for Functional Modelling).

● Project scheduling methods are focused mainly on the basic RCPSP model. In the kinematic model presented here, project scheduling is considered as a kinematic chain (open (serial), closed (parallel) and/or hybrid) formed by a set of rigid links (precedence of activities) that are connected by joints (project activities) with one fixed extremity (activity that represents the beginning of the project) and one free extremity (activity that represents the end of the project), which are represented by a homogeneous transformation matrix.

● The literature on project scheduling states that the generation of proactive (robust) multi-resource baseline schedules in combination with efficient and effective reactive schedule repair mechanisms constitutes a viable area of future research. The kinematic model presented in this chapter provides this combination through the direct and inverse kinematic models. It provides evidence of the influences stemming from uncertainties in project activities, enabling the balancing of durations and resources between project activities and between projects.

Kinematic fundamentals for the robotic manipulators and for the model proposed by this chapter

This topic aims to present the main fundamentals related to the kinematic problems for the robotic manipulators or industrial robots, as well as to present the main fundamentals related to the kinematic model proposed by this chapter for project scheduling with constrained resources under uncertainties.

KINEMATIC PROBLEMS FOR ROBOTIC MANIPULATORS

In order to describe and represent the spatial geometry of the links of a robotic manipulator with to a fixed reference coordinate system, Denavit and Hartenberg (D-H) proposed a systematic approach utilizing matrix algebra. This systematic approach reduces the direct kinematic problem to finding an equivalent 4x4 homogenous transformation matrix that describes the spatial relationship between two adjacent rigid links with respect to a fixed reference coordinate system.

In the inverse kinematic problem, given the position and orientation of the end-effector, we would wish to find the corresponding joint variables of the robotic manipulator. The inverse kinematic problem is not as simple as the direct kinematic problem, because the kinematic equations are nonlinear and their solution is not easy (or even possible) in a close form. The inverse kinematic problem may be solved by various methods, such as inverse transform of Paul, screw algebra of Kohli and Soni, dual matrices of Denavit, dual quaternion of Yang and Freudenstein, iterative of Uicker, geometric approaches of Lee and Ziegler and others. Figure 3 represents a synthesis to the direct and inverse kinematic problem.

FIGURE 3.

Synthesis to the direct and inverse kinematic problem for robotic manipulators.

KINEMATIC MODELS FOR COUPLED ESTIMATE TECHNIQUE

Basically, the project consists of a set of activities that must be performed in order to complete the project. The kinematic model technique for project scheduling with constrained resources under uncertainties named as Coupled Estimate Technique deals with the movements in the scheduled activities without consideration of the causes of the movements. Each project activity has a set of attributes represented by activity estimates (duration, resource and precedence), activity uncertainties (duration, resources and critical factor) and activity variables (duration and resource).

The outcomes of activities depend of their attributes, and the analytical kinematic model provides a metaschedule to the project. To model a project activity with kinematic model, it is assumed that the activity estimates are the constants, the kinematic equations are the orientation, and the modelled outcomes depend of the uncertainties and variables. Thus, the kinematic model may be direct or inverse type according to Figure 4.

FIGURE 4.

Kinematic model for Coupled Estimate Technique.

Therefore, given the activity uncertainties determined by the project team, the direct kinematic model or the CET may be used to model the activity variables. Moreover, given the activity variables determined by the project team, using the inverse kinematics or the CET, the activity uncertainties may be modelled. It is important to emphasize that the estimates of the activity attributes must be part of organizational policy used by the team during the project planning. Figure 5 illustrates the kinematic model or the CET with the IDEF0 language.

FIGURE 5.

(a) Direct kinematic model and (b) inverse kinematic model.

Coupled Estimate Technique concepts

Coupled Estimative Technique (CET) is a project scheduling artefact to model the project activity with constrained resources under uncertainties. This section presents the main aspects of the CET that provide the mathematical formulation involving the activity estimates (duration, resource and precedence), activity uncertainties (duration, resources and critical factor) and activity variables (duration and resource).

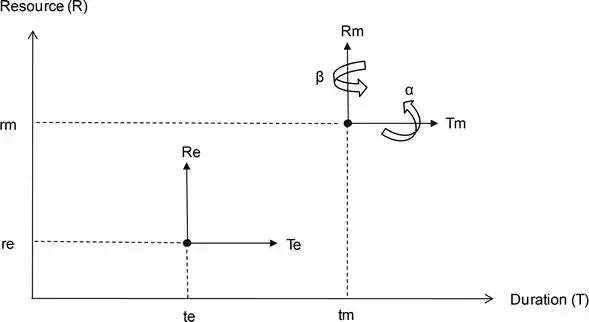

Let each project activity be represented in the two-dimensional Cartesian coordinate system (0, T, R) where the abscissa is the duration axis (T) and the ordinate is the resource axis (R). The value set of the duration and resource for project activity lies between the estimated ordered pair (estimated duration (te) and estimated resource (re)) and the modelled ordered pair (modelled duration (tm) and modelled resource (rm)).

Estimated ordered pair is represented in the estimated coordinate system (0, Te, Re), and the modelled ordered pair is represented in the modelled coordinate system (0, Tm, Rm). The rotation alpha expresses the uncertainty in the estimation of the activity duration, and the rotation beta expresses the uncertainty in the estimation of activity resource. Figure 6 shows the graphical representation of one project activity.

FIGURE 6.

Graphical representation of one project activity.

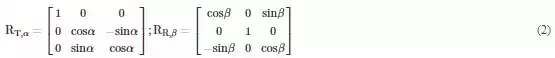

The mathematical formulation of the CET used to model the project activities is obtained by algebraic operations with homogeneous transformation matrices (4 × 4). They map a project activity from estimated coordinate system (estimated ordered pair) to modelled coordinate system (modelled ordered pair) using the homogeneous coordinate notation. The homogeneous transformation matrix (H) consists of four submatrices, according to Eq. (1):

![]()

The rotation submatrix (R3 × 3) transforms one project activity expressed in the estimated coordinate system to the modelled coordinate system. For project scheduling, the rotation submatrices are used to produce the effect of the uncertainty in the estimation of the activity duration by rotation alpha at the duration axis and the effect of the uncertainty in the estimation of activity resource by rotation beta at the resource axis. According to, the basic rotation matrices are shown in Eq. (2), rotation alpha at the duration axis and rotation beta at the resource axis:

As the duration and resource of the project activity vary between estimated and modelled values, the position submatrix (P3 × 1) represents the coordinates of the estimated ordered pair. Therefore, the first element of the position submatrix is the duration translation or the estimated duration (te), the second element of the position submatrix is the resource translation or the estimated resource (re), and as the project activity is represented in a geometric plane, the third element is null. The position submatrix (P3 × 1) is shown in Eq. (3):

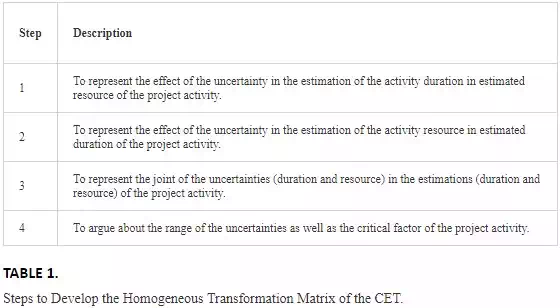

The perspective transformation submatrix (1 × 3) is useful for computer vision and the calibration of camera models. For the mathematical formulation of the CET, the elements of this submatrix are set to zero to indicate null perspective transformation. The fourth diagonal element is the global scaling factor (1 × 1), which is set to 1 in this work. Values different from 1 are commonly used in computer graphics as a universal scale factor taking on any positive values. The project activity is mathematically represented through homogeneous transformation matrices (4 × 4) which are arranged in four steps to obtain the continuous duration and cost functions as described in Table 1.

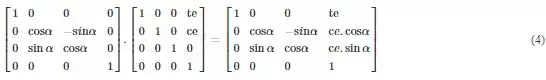

The first step is performed through the product between the homogeneous matrices (HT, α) and (Hte; re), where (HT, α) means a rotation alpha on the duration axis and (Hte; re) means a translation in the duration and resource axes. The algebraic operation of Eq. (4) corresponds to the effect of the uncertainty in the estimation of the activity duration in estimated resource of the project activity:

The first element of the position submatrix (P3 × 1) in Eq. (4) represents the activity duration; the second represents the estimated resource varying according to the uncertainty in the estimation of the activity duration. As the position submatrix (P3 × 1) is a spatial geometric representation (abscissa, ordinate and cote), the third element may be disregarded because the project activity is a plane geometric representation (abscissa and ordinate).

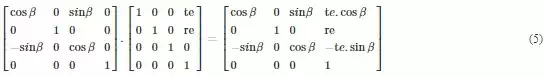

The second step listed in Table 1 performs the product between the homogeneous matrices (HT, β) and (Hte; re). The former is the homogeneous matrix composed by a rotation beta on the resource axis, and (Hte; re) means a translation in the duration and resource axes. The algebraic operation of Eq. (5)corresponds to the effect of the uncertainty in the estimation of the activity resource in estimated duration of the project activity:

The first element of the submatrix (P3 × 1) in Eq. (5) represents the activity duration varying according to the uncertainty in the estimation of the activity resource; the second, the activity resource. The third element of the submatrix (P3 × 1) in Eq. (5) may be discarded because the project activity is mapped at the geometric plane. The negative signal arises because the projection of the duration translation is at the negative semi axis of the cote coordinate.

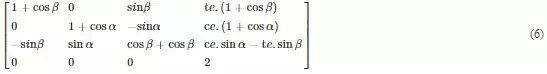

The third step prescribed in Table 1 performs the sum between Eqs. (4) and (5). The summation shown in Eq. (6) represents the Coupled Estimate Technique (CET) overall homogeneous matrix that provides the joint effect of the uncertainties (duration and resource) in the estimations (duration and resource) of the project activity:

The first element of the position submatrix (P3 × 1) in Eq. (6) represents the modelled duration in function of the estimated duration and uncertainty in the estimation of the activity resource. The second element represents the modelled resource in function of the estimated resource and uncertainty in the estimation of the activity duration. As the project activity is mapped at the geometric plane, the third element may be disregarded. However, it might be used to represent other project goals, e.g. the quantification of the activity performance or quality.

And finally, the fourth step in Table 1 performs some orientations about the range of the uncertainties (duration and resource) and the critical factor of the project activity:

● The uncertainties must range between 0° (highest degree of uncertainty) and 89° (lowest degree of uncertainty). When alpha and beta equal to 0°, the modelled duration equals to the double of estimated duration (2te), and the modelled resource equals to the double of estimated resource (2re).

● When alpha and beta equal to 90°, there are no uncertainties or certainties. Therefore, the modelled duration equals to the estimated duration (te), and the modelled resource equals to the estimated resource (re).

● The certainties must range between 91° (lowest degree of certainty) and 180° (highest degree of certainty). When alpha and beta equal to 180°, the duration and resource modelled are null; this means a dummy activity, i.e. a project activity without duration and resource.

● The critical factor (theta) of the project activity must be unitary for cases where the modelled value is less than or equal to double of the estimated value, and the critical factor (theta) must be greater than one for cases where the modelled value is greater than double what was estimated value.

Table 2 shows the mathematical formulations for one project activity of the Coupled Estimate Technique.

|

Modelled variables |

Equations |

|

Duration |

tm = θ. te. (1 + cos β) |

|

Resource |

rm = θ. re. (1 + cos α) |

TABLE 2.

Mathematical formulation of the CET.

Implementation of the direct kinematic model with CET

To demonstrate how the direct kinematic model is implemented, this section presents a didactic example with scheduling of duration in days, one type of resource (financial in dollar) and the critical factor unitary for all activities present in the critical path, according to the four sequential tasks. The main objective is to obtain the modelled schedule or project duration modelled (pdm) and modelled budget or project resource modelled (prm) with the effects of uncertainties of the estimates in the planned schedule or project duration estimated (pde) and planned budget or project resource estimated (pre) of the project. Assuming a critical path with the activities in the project precedence diagram which have the attributes:

● A0: Project beginning

● A1: Duration estimation equal to 30 days with uncertainty equal to 45°; resource estimation equal to $100 with uncertainty equal to 45°

● A2: Duration estimation equal to 20 days with uncertainty equal to 45°; resource estimation equal to $50 with uncertainty equal to 45°

● A3: End of project

As task 1 for implementation of the direct kinematic model with CET, the planned schedule and budget without the uncertainties must be determined; thus, the planned schedule or project duration estimated (pde) is equal to 50 days, and the planned budget or project resource estimated (pre) is equal to $150.

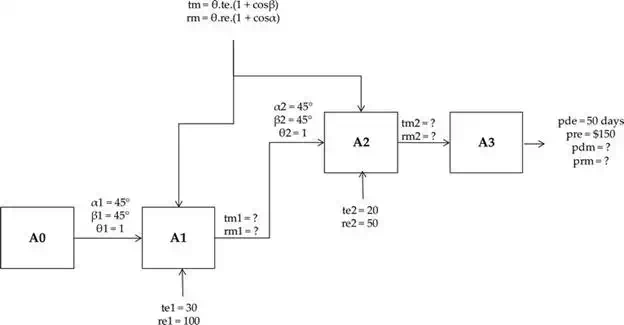

In task 2, the project precedence diagram is modelled with IDEF0 from the attributes of the project activities. Figure 7 presents the IDEF0 with:

● Activities estimates (te1, re1; te2, re2)

● Activity uncertainties (α1, β1, θ1; α2, β2, θ2)

● Activity variables to be modelled (tm1, rm1; tm2, rm2)

● Project duration estimated (pde) and project resource estimated (pre)

● Project duration modelled (pdm) and project resource modelled (prm) to be modelled

FIGURE 7.

Project precedence diagram with IDEF0 for direct kinematic model with CET.

During the third task, the modelled variables are calculated according to the kinematic equations of the CET presented in Table 2 and Figure 4. From the estimates and uncertainties of the activities, the modelled variables of project activities are presented in Table 3.

|

Activities |

Estimates |

Uncertainties |

Modelled variables |

|

A1 |

te1 = 30 days |

α1 = 45° |

51 days |

|

re1 = $100 |

β1 = 45° |

$170 |

|

|

A2 |

te2 = 20 days |

α2 = 45° |

34 days |

|

re2 = $50 |

β2 = 45° |

$85 |

TABLE 3.

Modelled variables of the project activities.

And finally, the fourth task describes that the project duration modelled (pdm) is equal to the sum of the modelled durations, and project resource modelled (prm) is equal to the sum of the modelled resources. Table 4 presents the project scheduling modelled according to the direct kinematic model with CET.

|

Project |

Estimates |

Modelled |

Effects |

|

Duration |

pde = 50 days |

pdm = 85 days |

35 days besides of planned |

|

Resource |

pre = $150 |

prm = $255 |

$85 besides of planned |

TABLE 4.

Project scheduling modelled according to the direct kinematic model with CET.

Analyzing the information in Table 4, due to the uncertainties in the estimation of the project duration, the schedule should be increased in 35 days that represent 70% besides of the project duration estimated. In the same manner, due to the uncertainties in the estimation of the project resource, the budget should be increased in $85 that represents 70% besides of the project resource estimated.

Implementation of the inverse kinematic model with CET

To demonstrate how the inverse kinematic model is implemented, this section presents a didactic example with scheduling of duration in days, one type of resource (financial in dollar) and the critical factor unitary for all activities present in the critical path, according to the four sequential tasks. The main objective is to obtain the modelled uncertainties in the estimation of the project durations and resources from estimated and performed values of the project activities. Assuming a critical path with the activities in the project precedence diagram which have the attributes:

● A0: Project beginning

● A1: Duration estimation equal to 30 days and duration performed equal to 51 days; resource estimation equal to $100 and resource performed equal to $170

● A2: Duration estimation equal to 20 days and duration performed equal to 34 days; resource estimation equal to $50 and resource performed equal to $85

● A3: End of project

As task 1 for implementation of the inverse kinematic model with CET, the planned schedule and budget as well as the performed schedule and budget with the effects of the uncertainties must be determined; thus, the planned schedule or project duration estimated (pde) is equal to 50 days, the planned budget or project resource estimated (pre) is equal to $150, the performed schedule or project duration performed (pdp) is equal to 85 days and the performed budget or project resource performed (prp) is equal to $255.

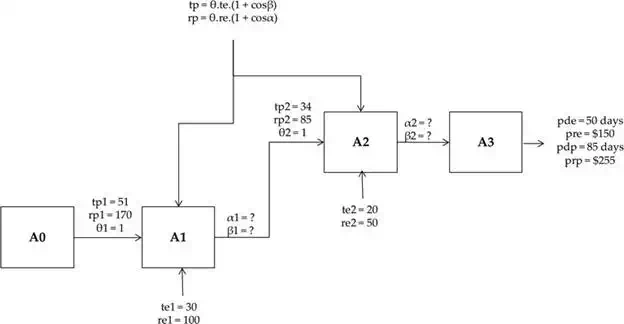

In task 2, the project precedence diagram is modelled with IDEF0 from the attributes of the project activities. Figure 8 presents the IDEF0 with:

● Activity estimates (te1, re1; te2, re2)

● Activity uncertainties (α1, β1, θ1; α2, β2, θ2) to be modelled

● Activity variables, which for inverse kinematic model, the performed duration and resource (tp1, rp1; tp2, rp2)

● Project duration estimated (pde) and project resource estimated (pre)

● Project duration performed (pdp) and project resource performed (pre)

FIGURE 8.

Project precedence diagram with IDEF0 for inverse kinematic model with CET.

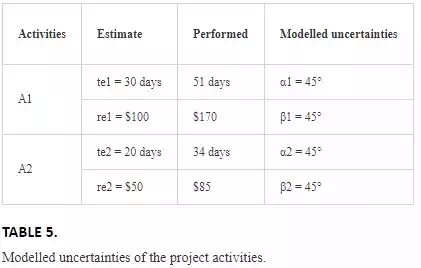

For the third task, the kinematic equations of the CET presented in Table 2 must be tailored where the modelled variables are substituted by the performed variables according to Figure 5. From the estimated and performed values, the modelled uncertainties of project activities are presented in Table 5.

In task 4, the uncertainty of the project must be analyzed. There are some ways to determine the project uncertainty; frequently, this choice is realized by the project team taking account the nature and challenges of the project. The following are some suggestions:

● The project uncertainty may be determined by the average between the uncertainties of the activities, where for the case studied in this section, the project uncertainty for the duration and resource are equal to 45°.

● The project uncertainty may be determined by the greater or lower uncertainty of the activities.

● The project uncertainty may be determined by the sum with the weight of uncertainties of the activities.

Comments and conclusions

This chapter represented one interesting example of cross-fertilization between different areas, where the manipulator kinematic concepts (direct and inverse) were tailored and implemented in order to provide an innovative solution for project scheduling with constrained resources under uncertainties. Basically, the homogeneous transformation matrices (4 × 4) were used to model the schedule (time) and budget (resource) of the projects taking account the uncertainties in the estimates.

In the perspective of the project management, the direct kinematic model may be used to the project scheduling in order to model the schedule and budget when the duration and resource estimations are not known completely; therefore, there are degrees of uncertainties related to duration and resource estimation. And, the inverse kinematic model may be used to the implemented projects in order to model or quantify the degrees of uncertainties related to duration and resource estimation. These modelled uncertainties of the implemented project may be used during the project scheduling of similar projects.

The modelled outcomes provide information that can enhance the processes for schedule and budget of the project management, helping to achieve project scheduling of a project. They also provide information about project risk management processes, helping to identify, analyze and respond to uncertainties that are not definitely known but pose the potential for favourable or, more likely, adverse consequences on project objectives (duration and resources).

However, the model represents a conjecture of a phenomenon and, therefore, an approximation of the behaviour of that phenomenon. Thus, the modelled outcomes of the kinematic model for project scheduling with constrained resources under uncertainties must be critically analyzed by a project team.