Robots in Engineering and Manufacturing

From the inspiration of the miraculous robot origins of the 1960s to the far-fetched imagination portrayed in movies, we see how robots have digressed from their silver screen persona to create an impact in our day-to-day lives in a practical sense.

The mere mention of the word robot conjures images of human-like machines capable of intelligent interaction with the world around them. From the robots of odd shapes and forms in George Lucasís original "Star Wars" of 1977 to the lifelike robots shown more recently in the 2004 movie "I, Robot" adapted from Isaac Asimovís classic novel of 1950, these androids, equipped with fictitious highly advanced artificial intelligence by their makers, were able to mimic human intelligence and thrive and survive through all forms of challenges and obstacles in their environment. Another incredible example of robots that have been put to great film effect is found in the movie Transformers, an adaptation from the animated series of the 1980s. Although recent years have seen almost similar commercially-produced robots in the form of AIBO and ASIMO introduced by Sony and Honda respectively, the real practical use of robots in the engineering industry is a huge contrast to what their persona from the silver screen would suggest.

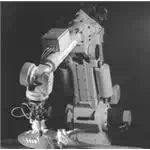

†In the real world, robots are utilised to perform repetitive tasks and job functions which are in likelihood too tedious and boring for man to perform, such as in the manufacturing line of plastics and various hardware. These practical robots often take the form of mechanical arms equipped with electromagnetic plates, grippers, or suction cups working in tandem with conveyor belts to aid in the assembly of equipment in the manufacturing industries. Although stationary in nature, these robotic arms are endowed with several degrees-of-freedom, giving them the flexibility to move in many directions through multiple angles with utmost ease and agility.

Robots can also be made to execute difficult activities and processes requiring high precision at an accuracy usually beyond human capabilities. Through proper programming, a task can be repeatedly carried out with minimal or virtually without error. With proximity and pressure sensors abound, the accuracy which can be achieved by some of these robots can be rather remarkable, and allow them to work with extremely fragile materials with great care. Even enervating jobs requiring skill and expertise such as arc welding and spray painting can seem like childís play to a robot.

Robots are also best employed in situations which may prove to be too dangerous for man to perform. In steel manufacturing mills, robots are used in materials handling and transfer, to load iron ore and coke into blast furnaces and move molten iron, a chore perhaps too life-threatening for man himself to undertake. With practical use of robots such as these, accidents and loss of life at the industrial workplace can be minimized. Also, with the capability of withstanding stress far beyond what human being can endure, these tireless machines have a proven reliability and a track record in getting the job done right without the adversities and risks commonly associated with human error and behaviour.

Robots have also assisted man in accomplishing job duties in environments which are not conducive to human life. In space exploration, the rover spacecraft robots had been successfully deployed by NASA in their Mars Exploration Rover Mission to survey and explore the surface of Mars, and to retrieve geological samples from the red planet. In marine engineering, robots known as autonomous underwater vehicles (AUVs) serve to produce detailed maps of the seabed for the oil and gas industry, as well as for research into deep underwater chemical compound composition and the presence of microorganisms without any risk to human life.

In HVAC applications, robots equipped with sensors and brushes are commonly used to effectively clean air-conditioning ducts in the engineering maintenance of commercial buildings. Camera sensors are sometimes installed on these robots to allow their human operator a glimpse of duct interiors that are mostly too narrow and tight for humans to work inside them. Similar robots have also recently found their way into residential homes, performing the same automated cleansing duties on floors and carpets.

Robotic Arm

In closing, robots have established their place as dependable servants in the daily lives of human beings, with robotic technology playing a vital role in the engineering industry. Robots have been reliable in getting their assigned responsibilities accomplished correctly and accurately with great efficiency, and keeping their human masters safe from harm in the process.