Wind Turbine

Aerodynamics Design

The wind turbine

aerodynamics of a horizontal-axis wind turbine (HAWT) are not

straightforward. The air flow at the blades is not the same as the airflow

further away from the turbine. The very nature of the way in which energy is

extracted from the air also causes air to be deflected by the turbine. In

addition the aerodynamics of a wind turbine at the rotor surface exhibit

phenomena that are rarely seen in other aerodynamic fields.

Axial momentum and the Betz limit

Energy in fluid is contained

in four different forms: gravitational potential energy, thermodynamic

pressure, kinetic energy from the velocity and finally thermal energy.

Gravitational and thermal energy have a negligible effect on the energy

extraction process. From a macroscopic point of view, the air flow about the

wind turbine is at atmospheric pressure. If pressure is constant then only

kinetic energy is extracted. However up close near the rotor itself the air

velocity is constant as it passes through the rotor plane. This is because of

conservation of mass. The air that passes through the rotor cannot slow down

because it needs to stay out of the way of the air behind it. So at the rotor

the energy is extracted by a pressure drop. The air directly behind the wind

turbine is at sub-atmospheric pressure; the air in front is under greater than

atmospheric pressure. It is this high pressure in front of the wind turbine

that deflects some of the upstream air around the turbine.

Albert Betz and Frederick W. Lanchester were the first to

study this phenomenon. Betz notably determined the maximum limit to wind

turbine performance. The limit is now referred to as the Betz limit. This is

derived by looking at the axial momentum of the air passing through the wind

turbine. As stated above some of the air is deflected away from the turbine.

This causes the air passing through the rotor plane to have a smaller velocity

than the free stream velocity. The ratio of this reduction to that of the air

velocity far away from the wind turbine is called the axial induction factor.

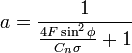

It is defined as below:

![]()

where: a is

the axial induction factor, U1 is the wind speed far away

upstream from the rotor, and U2 is the wind speed at the rotor.

The first step to deriving the Betz limit is applying

conservation of axial momentum. As stated above the wind loses speed after the

wind turbine compared to the speed far away from the turbine. This would

violate the conservation of momentum if the wind turbine was not applying a

thrust force on the flow. This thrust force manifests itself through the

pressure drop across the rotor. The front operates at high pressure while the

back operates at low pressure. The pressure difference from the front to back

causes the thrust force. The momentum lost in the turbine is balanced by the

thrust force.

Another equation is needed to relate the pressure difference

to the velocity of the flow near the turbine. Here the Bernoulli equation is

used between the field flow and the flow near the wind turbine. There is one

limitation to the Bernoulli equation: the equation cannot be applied to fluid

passing through the wind turbine. Instead conservation of mass is used to

relate the incoming air to the outlet air. Betz used these equations and

managed to solve the velocities of the flow in the far wake and near the wind

turbine in terms of the far field flow and the axial induction factor. The

velocities are given below as:

U2 = U1(1 − a)

U4 = U1(1 − 2a)

U4 is

introduced here as the wind velocity in the far wake. This is important because

the power extracted from the turbine is defined by the following equation.

However the Betz limit is given in terms of the coefficient of power. The

coefficient of power is similar to efficiency but not the same. The formula for

the coefficient of power is given beneath the formula for power:

![]()

![]()

Betz was able to develop an expression for Cp in

terms of the induction factors. This is done by the velocity relations being

substituted into power and power is substituted into the coefficient of power

definition. The relationship Betz developed is given below:

Cp = 4a(1 − a)2

The Betz limit is defined by the maximum value that can be

given by the above formula. This is found by taking the derivative with respect

to the axial induction factor, setting it to zero and solving for the axial

induction factor. Betz was able to show that the optimum axial induction factor

is one third. The optimum axial induction factor was then used to find the

maximum coefficient of power. This maximum coefficient is the Betz limit. Betz

was able to show that the maximum coefficient of power of a wind turbine is

16/27. Airflow operating at higher thrust will cause the axial induction factor

to rise above the optimum value. Higher thrust cause more air to be deflected

away from the turbine. When the axial induction factor falls below the optimum

value the wind turbine is not extracting all the energy it can. This reduces

pressure around the turbine and allows more air to pass through the turbine,

but not enough to account for lack of energy being extracted.

The derivation of the Betz limit shows a simple analysis of

wind turbine aerodynamics. In reality there is a lot more. A more rigorous

analysis would include wake rotation, the effect of variable geometry. The

effect of air foils on the flow is a major component of wind turbine

aerodynamics. Within airfoils alone, the wind turbine aerodynamicist has to

consider the effect of surface roughness, dynamic stall tip losses, solidity,

among other problems.

Angular momentum and wake rotation

The wind turbine described by Betz does not actually exist.

It is merely an idealized wind turbine described as an actuator disk. It's a

disk in space where fluid energy is simply extracted from the air. In the Betz

turbine the energy extraction manifests itself through thrust. The equivalent

turbine described by Betz would be a horizontal propeller type operating with

infinite blades at infinite tip speed ratios and no losses. The tip speed ratio

is ratio of the speed of the tip relative to the free stream flow. This turbine

is not too far from actual wind turbines. Actual turbines are rotating blades.

They typically operate at high tip speed ratios. At high tip speed ratios three

blades are sufficient to interact with all the air passing through the rotor plane.

Actual turbines still produce considerable thrust forces.

One key difference between actual turbines and the actuator

disk, is that the energy is extracted through torque. The wind imparts a torque

on the wind turbine, thrust is a necessary by-product of torque. Newtonian

physics dictates that for every action there is an equal and opposite reaction.

If the wind imparts a torque on the blades then the blades must be imparting a

torque on the wind. This torque would then cause the flow to rotate. Thus the

flow in the wake has two components, axial and tangential. This tangential flow

is referred to as wake rotation.

Torque is necessary for energy extraction. However wake

rotation is considered a loss. Accelerating the flow in the tangential

direction increases the absolute velocity. This in turn increases the amount of

kinetic energy in the near wake. This rotational energy is not dissipated in

any form that would allow for a greater pressure drop (Energy extraction). Thus

any rotational energy in the wake is energy that is lost and unavailable.

This loss is minimized by allowing the rotor to rotate very

quickly. To the observer it may seem like the rotor is not moving fast;

however, it is common for the tips to be moving through the air at 6 times the

speed of the free stream. Newtonian mechanics defines power as torque

multiplied by the rotational speed. The same amount of power can be extracted

by allowing the rotor to rotate faster and produce less torque. Less torque

means that there is less wake rotation. Less wake rotation means there is more

energy available to extract.

Blade Element and Momentum Theory

The simplest model for horizontal axis wind turbine (HAWT)

aerodynamics is Blade Element Momentum (BEM) theory. The theory is based on the

assumption that the flow at a given annulus does not affect the flow at

adjacent annuli. This allows the rotor blade to be analyzed in sections, where

the resulting forces are summed over all sections to get the overall forces of

the rotor. The theory uses both axial and angular momentum balances to

determine the flow and the resulting forces at the blade.

The momentum equations for the far field flow dictate that

the thrust and torque will induce a secondary flow in the approaching wind.

This in turn affects the flow geometry at the blade. The blade itself is the

source of these thrust and torque forces. The force response of the blades is

governed by the geometry of the flow, or better known as the angle of attack.

Refer to the Airfoil article for more information on how airfoils create lift

and drag forces at various angles of attack. This interplay between the far

field momentum balances and the local blade forces requires one to solve the

momentum equations and the airfoil equations simultaneously. Typically computers

and numerical methods are employed to solve these models.

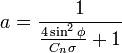

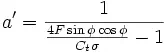

There is a lot of variation between different version of BEM

theory. First, one can consider the effect of wake rotation or not. Second, one

can go further and consider the pressure drop induced in wake rotation. Third,

the tangential induction factors can be solved with a momentum equation, an

energy balance or orthognal geometric constraint; the latter a result of

Biot-Savart law in vortex methods. These all lead to different set of equations

that need to be solved. The simplest and most widely used equations are those

that consider wake rotation with the momentum equation but ignore the pressure

drop from wake rotation. Those equations are given below. a is the axial

component of the induced flow, a' is the tangential component of the induced

flow. σ is the solidity of the rotor, φ is the local inflow

angle. Cn and Ct are

the coefficient of normal force and the coefficient of tangential force

respectively. Both these coefficients are defined with the resulting lift and

drag coefficients of the airfoil:

Corrections to Blade Element Momentum theory

Blade Element Momentum (BEM) theory alone fails to accurately

represent the true physics of real wind turbines. Two major shortcomings are

the effect of discrete number of blades and far field effects when the turbine

is heavily loaded. Secondary short-comings come from dealing with transient

effects like dynamic stall, rotational effects like coriolis and centrifugal

pumping, finally geometric effects that arise from coned and yawed rotors. The

current state of the art in BEM uses corrections to deal with the major

shortcoming. These corrections are discussed below. There is as yet no accepted

treatment for the secondary shortcomings. These areas remain a highly active

area of research in wind turbine aerodynamics.

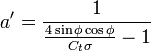

The effect of the discrete number of blades is dealt with by

applying the Prandtl tip loss factor. The most common form of this factor is

given below where B is the number of blades, R is the outer radius and r is the

local radius. The definition of F is based on actuator disk models and not

directly applicable to BEM. However the most common application multiplies

induced velocity term by F in the momentum equations. As in the momentum

equation there are many variations for applying F, some argue that the mass

flow should be corrected in either the axial equation, or both axial and

tangential equations. Others have suggested a second tip loss term to account

for the reduced blade forces at the tip. Shown below are the above momentum

equations with the most common application of 'F':

![]()

The typical momentum theory applied in BEM is only effective

for axial induction factors up to 0.4 (thrust coefficientof 0.96). Beyond this

point the wake collapses and turbulent mixing occurs. This state is highly

transient and largely unpredictable by theoretical means. Accordingly, several

empirical relations have been developed. As the usual case there are several

version, however a simple one that is commonly used is a linear curve fit given

below, with ac = 0.2. The turbulent wake function

given excludes the tip loss function, however the tip loss is applied simply by

multiplying the resulting axial induction by the tip loss function.

![]() when a > ac

when a > ac

Please note the following: do not confuse CT and Ct,

the first one is the thrust coefficient of the rotor, which is the one which

should be corrected for high rotor loading (i.e. for high values of a),

whilst the second one (ct) is the tangential aerodynamic

coefficient of an individual blade element, which is given by the aerodynamic

lift and drag coefficients.

Other Methods of Aerodynamic Modeling

BEM is widely used due to its simplicity and overall

accuracy, but its originating assumptions limit its use when the rotor disk is

yawed, or when other non-axisymmetric effects (like the rotor wake) influence

the flow. Limited success at improving predictive accuracy has been made using

computational fluid dynamics (CFD) solvers based on Reynolds Averaged Navier

Stokes (RANS) and other similar three-dimensional models such as free vortex

methods. These are very computationally-intensive simulations to perform for

several reasons. First, the solver must accurately model the far-field flow

conditions, which can extend several rotor diameters up- and down-stream and

include atmospheric boundary layer turbulence, while at the same time resolving

the small-scale boundary-layer flow conditions at the blades' surface

(necessary to capture blade stall). In addition, many CFD solvers have

difficulty meshing parts that move and deform, such as the rotor blades.

Finally, there are many dynamic flow phenomena that are not easily modelled by

RANS, such as dynamic stall and tower shadow. Due to the computational

complexity, it is not currently practical to use these advanced methods for

wind turbine design, though research continues in these and other areas related

to helicopter and wind turbine aerodynamics.

Free vortex models (FVM) and Lagrangian particle vortex

methods (LPVM) are both active areas of research that seek to increase

modelling accuracy by accounting for more of the three-dimensional and unsteady

flow effects than either BEM or RANS. FVM is similar to lifting line theory in

that it assumes that the wind turbine rotor is shedding either a continuous

vortex filament from the blade tips (and often the root), or a continuous

vortex sheet from the blades' trailing edges. LPVM can use a variety of methods

to introduce vorticity into the wake. Biot-Savartsummation is used to determine

the induced flow field of these wake vorticies' circulations, allowing for

better approximations of the local flow over the rotor blades. These methods

have largely confirmed much of the applicability of BEM and shed insight into

the structure of wind turbine wakes. FVM has limitations due to its origin in

potential flow theory, such as not explicitly modelling model viscous behavior,

though LPVM is a fully viscous method. LPVM is more computationally intensive

than either FVM or RANS, and FVM still relies on blade element theory for the

blade forces.