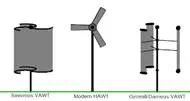

Types of Wind

Turbine

A wind turbine is

a device that converts kinetic energy from the wind into mechanical energy. If

the mechanical energy is used to produce electricity, the device may be called

a wind generator orwind charger. If the mechanical

energy is used to drive machinery, such as for grinding grain or pumping water,

the device is called a windmill or wind pump.

Wind turbines can rotate about

either a horizontal or a vertical axis, the former being both older and more

common.

Horizontal axis

Horizontal-axis wind turbines

(HAWT) have the main rotor shaft and electrical generator at the top of a

tower, and must be pointed into the wind. Small turbines are pointed by a

simple wind vane, while large turbines generally use a wind sensor coupled with

a servo motor. Most have a gearbox, which turns the slow rotation of the blades

into a quicker rotation that is more suitable to drive an electrical generator.

Since a tower produces turbulence behind it, the turbine is

usually positioned upwind of its supporting tower. Turbine blades are made

stiff to prevent the blades from being pushed into the tower by high winds.

Additionally, the blades are placed a considerable distance in front of the

tower and are sometimes tilted forward into the wind a small amount.

Downwind machines have been built, despite the problem of

turbulence (mast wake), because they don't need an additional mechanism for

keeping them in line with the wind, and because in high winds the blades can be

allowed to bend which reduces their swept area and thus their wind resistance.

Since cyclical (that is repetitive) turbulence may lead to fatigue failures,

most HAWTs are of upwind design.

Modern wind turbines

Turbines used in wind farms for commercial production of

electric power are usually three-bladed and pointed into the wind by

computer-controlled motors. These have high tip speeds of over 320 kilometres

per hour (200 mph), high efficiency, and low torque ripple, which contribute to

good reliability. The blades are usually colored light gray to blend in with

the clouds and range in length from 20 to 40 metres (66 to 130 ft) or more. The

tubular steel towers range from 60 to 90 metres (200 to 300 ft) tall. The

blades rotate at 10-22 revolutions per minute. At 22 rotations per minute the

tip speed exceeds 300 feet per second (91 m/s). A gear box is commonly used for

stepping up the speed of the generator, although designs may also use direct

drive of an annular generator. Some models operate at constant speed, but more

energy can be collected by variable-speed turbines which use a solid-state

power converter to interface to the transmission system. All turbines are

equipped with protective features to avoid damage at high wind speeds, by

feathering the blades into the wind which ceases their rotation, supplemented

by brakes.

Vertical axis design

Vertical-axis wind

turbines (or

VAWTs) have the main rotor shaft arranged vertically. Key advantages of this

arrangement are that the turbine does not need to be pointed into the wind to

be effective. This is an advantage on sites where the wind direction is highly

variable.

With a vertical axis, the generator and gearbox can be placed

near the ground, so the tower doesn't need to support it, and it is more

accessible for maintenance. Drawbacks are that some designs produce pulsating

torque.

It is difficult to mount vertical-axis turbines on towers,

meaning they are often installed nearer to the base on which they rest, such as

the ground or a building rooftop. The wind speed is slower at a lower altitude,

so less wind energy is available for a given size turbine. Air flow near the

ground and other objects can create turbulent flow, which can introduce issues

of vibration, including noise and bearing wear which may increase the

maintenance or shorten the service life. However, when a turbine is mounted on

a rooftop, the building generally redirects wind over the roof and this can double

the wind speed at the turbine. If the height of the rooftop mounted turbine

tower is approximately 50% of the building height, this is near the optimum for

maximum wind energy and minimum wind turbulence.

Subtypes

Darrieus wind turbine

"Eggbeater"

turbines, or Darrieus turbines, were named after the French inventor, Georges

Darrieus. They have good efficiency, but produce large torque ripple and

cyclical stress on the tower, which contributes to poor reliability. They also

generally require some external power source, or an additional Savonius rotor

to start turning, because the starting torque is very low. The torque ripple is

reduced by using three or more blades which results in a higher solidity for

the rotor. Solidity is measured by blade area divided by the rotor area. Newer

Darrieus type turbines are not held up by guy-wires but have an external

superstructure connected to the top bearing.

Giromill

A subtype of Darrieus turbine

with straight, as opposed to curved, blades. The cycloturbine variety has

variable pitch to reduce the torque pulsation and is self-starting.[18] The

advantages of variable pitch are: high starting torque; a wide, relatively flat

torque curve; a lower blade speed ratio; a higher coefficient of performance;

more efficient operation in turbulent winds; and a lower blade speed ratio

which lowers blade bending stresses. Straight, V, or curved blades may be used.

Savonius wind turbine

These are drag-type devices

with two (or more) scoops that are used in anemometers, Flettner vents

(commonly seen on bus and van roofs), and in some high-reliability

low-efficiency power turbines. They are always self-starting if there are at

least three scoops. They sometimes have long helical scoops to give a smooth

torque.