Figure 1: Jänschwalde power plant

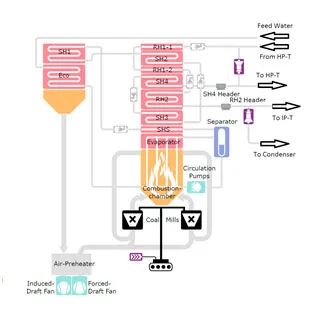

Figure 2: Schematics of boiler, economizer, reheaters and superheaters

As intermittent power production such as solar and wind power is increasing, the required flexibility of thermal power plants is also increasing. It is expected that the thermal power plants will experience more startups and stops, depending on electricity price and intermittent power production.

Today’s power plants are not designed for such frequent start-ups, and the thermal stress in certain components resulting from starts can be problematic. If the thermal stress is too high, the life-span of the plant is reduced.

One way to reduce the impact is to perform model-based optimized starts, which also could reduce the fuel consumption and environmental impact. This methodology requires a good model of the plant as well as a framework that can perform computations and optimizations. The main objectives of this collaboration were to create such a framework consisting of:

· A state estimator for the plant, that is an algorithm that updates the states of a plant model based on plant measurements.

· A non-linear model prediction controller (NMPC) that can, based on the result of the state estimator, optimize the control signals of the plant, to drive it towards a predefined operating condition while minimizing fuel costs and not violating thermal stress constraints.

As a starting point, the team had a very detailed Modelica model of a steam cycle in the plant from a collaboration between Vattenfall and Rostock University [5] and a simplified but uncalibrated model derived in [3], suitable for optimization. Both models were developed using Dymola.

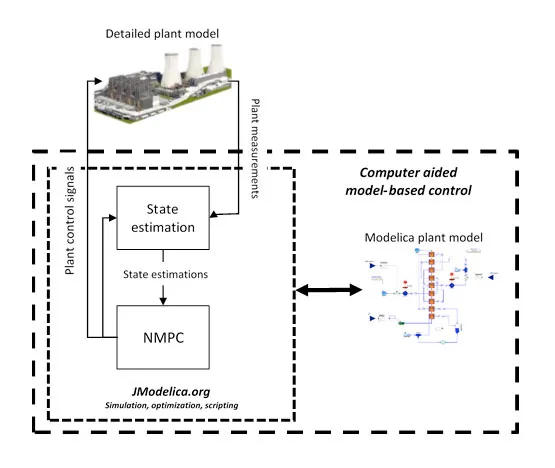

Additionally, a Python class in JModelica.org for NMPC, based on a Modelica model implemented in [2] was available. The control loop was to be used on the detailed Modelica model as a substitute for the real plant, see Figure 3.

Figure 3: Optimal control based on state estimation and NMPC.

There are several types of start-ups of a thermal power plant depending on how long the plant has been at stand still. In discussion with Vattenfall, it was decided that a soft-startup used when the plant has been shut down for 12-48 hours should be considered.

It was also decided that the focus would be on the initial phase of the start-up when oil burners are used to quickly start the combustion process, as this phase is the most costly part of the startup and hence when gains of optimization would potentially be greatest.

Both the state estimator and the NMPC used the simplified model where, compared to the detailed model, unused parts been removed and some highly detailed parts simplified. The dynamics in the simplified model focus on the components that are important at start-up. These components are the steam side and walls of heat exchangers and walls of headers and separators, where the thermal stress must be limited via control to not reduce plant life span.

The parameters of the simplified model, specifically the heat transfer coefficients in the heat exchangers and the pipe flow coefficients, were estimated to fit the detailed model during a reference soft start-up.

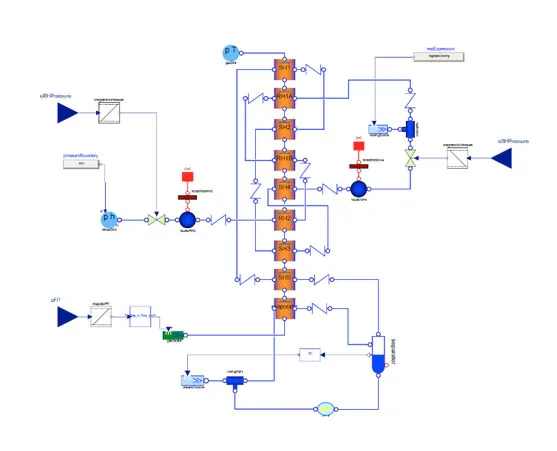

The simplified Modelica model of the steam cycle studied is seen in Figure 4.

Figure 4: Modelica model of one steam cycle of Jänschwalde

For state estimation of the thermal power plant, an unscented Kalman filter (UKF) was implemented by the team as a Python class. This class contains high-level functions to create an UKF from a generic Modelica model, perform predictions based on inputs and known states, and perform corrections based on measurements. The team ensured that the UKF were able to handle both model errors, by introducing disturbance states, as well as noise on all measured signals.

The available NMPC class in JModelica.org was used throughout the collaboration. A quadratic cost function, penalizing deviations from desired operating condition of firing power, live steam temperature and pressure, and reheater steam pressure, was used in the control loop.

Constraints on the thermal stress were set using soft constraints, meaning that the thermal stress can exceed the constraints but at a high cost in the optimization. Soft constraints are mainly used to prevent unfeasible optimization problems for the NMPC loop.

The team ran several types of tests to analyze the impact of different weights in the cost function on the optimal solution, as well as different types of model errors.

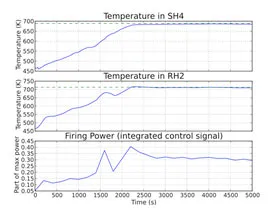

Figures 5 – 7 below show the results from a test with mismatch in the heat transfer coefficient of the evaporator, as well as disturbances acting on both boiler fire power and reheater by-pass valve.

Figure 5: Temperatures (blue) in superheater 4 and reheater 2 with setpoints (green) and boiler fire power (normalized). The solution with UKF and NMPC can make the thermal power plant reach the desired temperatures.

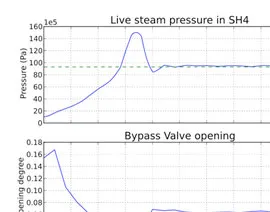

Despite these complications, the solution framework is able to drive the temperature and pressure in superheaters and reheater to desired values, as can be seen in the top graphs in Figures 5 and 6, using the firing power and by pass valve, shown in lower graphs in these two figures.

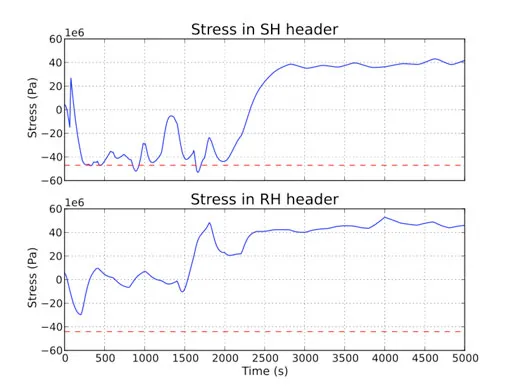

The thermal stress constraints shown in Figure 7 only have minor violations deemed acceptable from Vattenfall’s point of view.

Figure 6: Live steam pressure (blue) in super heater 4 with set-point (green) and by-pass valve opening. The solution with UKF and NMPC can make the thermal power plant reach desired live steam pressure.

Figure 7: Stress in superheater and reheater header (blue) and soft constraints (red-dashed). The solution with UKF and NMPC handles the thermal constraints so that they are violates as little as possible.