Steam Turbine Driven Electric Generator

The steam turbine-driven generators have

auxiliary systems enabling them to work satisfactorily and safely. The steam

turbine generator being rotating equipment generally has a heavy, large

diameter shaft. The shaft therefore requires not only supports but also has to

be kept in position while running. To minimise the frictional resistance to the

rotation, the shaft has a number of bearings. The bearing shells, in which the

shaft rotates, are lined with a low friction material like Babbitt metal. Oil

lubrication is provided to further reduce the friction between shaft and

bearing surface and to limit the heat generated.

Barring gear

Barring gear (or "turning gear")

is the mechanism provided to rotate the turbine generator shaft at a very low

speed after unit stoppages. Once the unit is "tripped" (i.e., the

steam inlet valve is closed), the turbine coasts down towards standstill. When

it stops completely, there is a tendency for the turbine shaft to deflect or

bend if allowed to remain in one position too long. This is because the heat

inside the turbine casing tends to concentrate in the top half of the casing,

making the top half portion of the shaft hotter than the bottom half. The shaft

therefore could warp or bend by millionths of inches.

This small shaft deflection, only

detectable by eccentricity meters, would be enough to cause damaging vibrations

to the entire steam turbine generator unit when it is restarted. The shaft is

therefore automatically turned at low speed (about one percent rated speed) by the

barring gear until it has cooled sufficiently to permit a complete stop.

Condenser

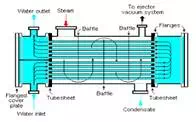

The surface condenser is a shell and tube

heat exchanger in which cooling water is circulated through the tubes. The

exhaust steam from the low pressure turbine enters the shell where it is cooled

and converted to condensate (water) by flowing over the tubes as shown in the

adjacent diagram. Such condensers use steam ejectors or rotary motor-driven

exhausters for continuous removal of air and gases from the steam side to

maintain vacuum.

For best efficiency, the temperature in the

condenser must be kept as low as practical in order to achieve the lowest

possible pressure in the condensing steam. Since the condenser temperature can

almost always be kept significantly below 100 °C where the vapor pressure of water is much less than atmospheric

pressure, the condenser generally works under vacuum. Thus leaks of non-condensible air into the closed loop must be

prevented. Plants operating in hot climates may have to reduce output if their

source of condenser cooling water becomes warmer; unfortunately this usually

coincides with periods of high electrical demand for air conditioning.

The condenser generally uses either

circulating cooling water from a cooling tower to reject waste heat to the atmosphere,

or once-through water from a river, lake or ocean.

Feedwater heater

In the case of a conventional

steam-electric power plant utilizing a drum boiler, the surface condenser

removes the latent heat of vaporization from the steam as it changes states

from vapour to liquid. The heat content (joules or Btu) in the steam is referred

to as enthalpy. The condensate pump then pumps the condensate water through

a feedwater heater. The feedwater heating equipment then raises the

temperature of the water by utilizing extraction steam from various stages of

the turbine.

Preheating the feedwater reduces

the irreversibilities involved in steam

generation and therefore improves the thermodynamic efficiency of the system.

This reduces plant operating costs and also helps to avoid thermal shock to the

boiler metal when thefeedwater is introduced

back into the steam cycle.

Superheater

As the steam is conditioned by the drying

equipment inside the drum, it is piped from the upper drum area into an

elaborate set up of tubing in different areas of the boiler. The areas known assuperheater and reheater.

The steam vapor picks up energy and its

temperature is now superheated above the saturation temperature. The

superheated steam is then piped through the main steam lines to the valves of

the high pressure turbine.

Deaerator

A steam generating boiler requires that the

boiler feed water should be devoid of air and other dissolved gases,

particularly corrosive ones, in order to avoid corrosion of the metal.

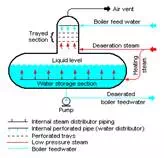

Generally, power stations use a deaerator

to provide for the removal of air and other dissolved gases from the boilerfeedwater. A deaerator typically includes a vertical, domeddeaeration section mounted on top of a horizontal

cylindrical vessel which serves as the deaerated boiler feedwater storage tank.

There are many different designs for a

deaerator and the designs will vary from one manufacturer to another. The

adjacent diagram depicts a typical conventional trayed deaerator.

If operated properly, most deaerator manufacturers will guarantee that oxygen

in the deaerated water will not exceed 7 ppb by weight (0.005 cm³/L).

Auxiliary systems

Oil system

An auxiliary oil system pump is used to

supply oil at the start-up of the steam turbine generator. It supplies the

hydraulic oil system required for steam turbine's main inlet steam stop valve,

the governing control valves, the bearing and seal oil systems, the relevant

hydraulic relays and other mechanisms.

At a preset speed

of the turbine during start-ups, a pump driven by the turbine main shaft takes

over the functions of the auxiliary system.

Generator heat dissipation

The electricity generator requires cooling

to dissipate the heat that it generates. While small units may be cooled by air

drawn through filters at the inlet, larger units generally require special

cooling arrangements. Hydrogen gas cooling, in an oil-sealed casing, is used

because it has the highest known heat transfer coefficient of any gas and for

its low viscosity which reduceswindage losses.

This system requires special handling during start-up, with air in the chamber

first displaced by carbon dioxide before filling with hydrogen. This ensures

that the highly flammable hydrogen does not mix with oxygen in the air.

The hydrogen pressure inside the casing is

maintained slightly higher than atmospheric pressure to avoid outside air

ingress. The hydrogen must be sealed against outward leakage where the shaft

emerges from the casing. Mechanical seals around the shaft are installed with a

very small annular gap to avoid rubbing between the shaft and the seals. Seal

oil is used to prevent the hydrogen gas leakage to atmosphere.

The generator also uses water cooling.

Since the generator coils are at a potential of about 22 kV and water is

conductive, an insulating barrier such as Teflon is used to interconnect the

water line and the generator high voltage windings. Demineralized water of low

conductivity is used.

Generator high voltage system

The generator voltage ranges from 11 kV in

smaller units to 22 kV in larger units. The generator high voltage leads are

normally large aluminum channels because of

their high current as compared to the cables used in smaller machines. They are

enclosed in well-grounded aluminum bus

ducts and are supported on suitable insulators. The generator high voltage

channels are connected to step-up transformers for connecting to a high voltage

electrical substation (of the order of 115 kV to 520 kV) for further

transmission by the local power grid.

The necessary protection and metering

devices are included for the high voltage leads. Thus, the steam turbine

generator and the transformer form one unit. In smaller units, generating at 11

kV, a breaker is provided to connect it to a common 11 kV bus system.