Which High-Performance Materials Are Used in Nuclear Reactors?

Growing cities, rise in population and the desire for a modern lifestyle has made the use of sophisticated gadgets inevitable. These gadgets demand a great deal of energy. Today, this has given rise to the fear of an energy crisis. To combat this problem, most countries rely heavily on power from coal and natural gas. This has resulted in increasing CO2 emissions, responsible for global warming.

The issues such as rising air pollution, limited land area and large variations in wind and sunlight make nuclear energy the most attractive option to overcome the shortage of energy in a sustainable way. The major issues faced by nuclear energy are safe nuclear waste disposal and safety during plant operation. Both issues can be tackled by continuous innovations in nuclear materials.

The presence of severe conditions acting in tandem such as radiation of varying energy, high temperature, highly corrosive environments and the combination of mechanical and thermal stresses makes this task challenging.

Traditional materials for nuclear reactors

Light Water Reactors (LWRs) make up 80% of the nuclear reactors in the world [1]. The two most common types of LWRs are the Boiling Water Reactor (BWR) and Pressurized Water Reactor (PWR). The major components of these reactors are fuel, metal cladding, the reflector, control rods, the moderator, reactor pressure vessel, and structural materials to provide support.

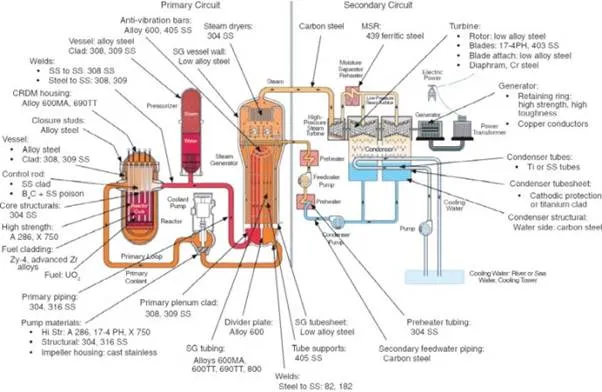

Figure 1: Schematic of materials used in a PWR

Figure 1: Schematic of materials used in a PWR

Fuel and metal cladding

The fuel in LWRs is ceramic UO2 in the form of pellets. Ceramic UO2 pellets maintain excellent dimensional stability during fission. These ceramic pellets are enclosed in a metal cladding. The fuel should have a high macroscopic fission cross-section and a low absorption cross-section at neutron energies of 0.025 eV.

Figure 2: Schematic of various interactions of a neutron with material

Figure 2: Schematic of various interactions of a neutron with material

The metal cladding should be transparent to neutrons so that these neutrons can cause fission of the UO2 fuel. To compare the neutron transparency of various metals, a parameter called the macroscopic neutron absorption cross-section is used. The lower the macroscopic neutron absorption cross-section, the better the cladding material. Additionally, the companies in charge of running these reactors need to burn the maximum amount of fuel in the reactor so as to extract the maximum amount of heat from the fuel. This is referred to as high fuel burnup. This leads to better plant economics, placing additional demands on fuel cladding most common being high corrosion resistance.

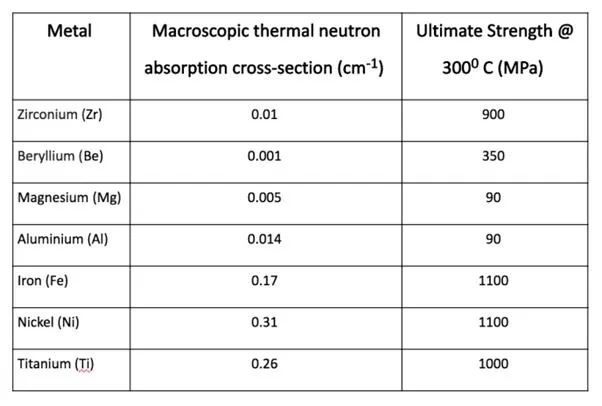

Table 1: Properties of Candidate materials for cladding application

Table 1: Properties of Candidate materials for cladding application

It is clear from Table 1 that beryllium, magnesium, and aluminium have the lowest neutron absorption cross-section, yet these metals are nevertheless not suitable for cladding applications. Beryllium is expensive, difficult to fabricate and toxic. Magnesium has a low melting point (650℃), loses its strength at high temperatures, and has poor resistance to hot water corrosion. Aluminium has a low melting point (660℃) and poor high-temperature strength .

Austenitic stainless steels (types 304, 316, and 347) have been previously used as cladding in BWRs, but they weren’t successful because of stress corrosion cracking (SCC) failure. Although austenitic steel-clad fuel operated reliably in PWRs , the need for higher fuel burnup eventually led to the replacement of austenitic stainless steel by Zr-based cladding .

Initially, the two major issues with zirconium were its poor corrosion resistance and high macroscopic thermal neutron absorption cross-section, but it was later discovered that its high macroscopic cross-section was due to the presence of small amounts of hafnium impurities in the zirconium. Alloying of Zr with small amounts of Sn, Cr, and Fe (less than 1%) was found to significantly increase the corrosion resistance.

Zircaloy was found to possess all the required properties such as:

· Relatively high abundance

· Not prohibitively expensive

· Good corrosion resistance at operating temperatures of 300℃

· Reasonable high-temperature strength

· Good fabricability .

However, after The Fukushima accident, the nuclear community is searching for an alternative material for Zircaloy as cladding. This will be discussed in detail in the next article.

11 March 2011, nuclear accident at Fukushima Daiichi Nuclear Power Plant

11 March 2011, nuclear accident at Fukushima Daiichi Nuclear Power Plant

These alloys were first chosen in the 1950s as a cladding material in LWRs by a US Navy Captain Hyman Rickover when Kaufman at MIT and Pomerance at Oak-Ridge came out with laboratory successes in separating hafnium from zirconium and showed that zirconium in its pure form absorbed only a few neutrons .

The corrosion mechanisms of Zircaloy are different in BWR and PWR environment. Zircaloy undergoes nodular corrosion in BWR whereas it undergoes uniform corrosion in PWR. Zircaloy 2 (resistant to nodular corrosion) is used as cladding in BWR and Zircaloy 4 (resistant to uniform corrosion) is used in PWR.

High burnup requires additional corrosion resistance, hence the two modern alloys in greatest current use are ZIRLO® from Westinghouse and M5™ from Framatome (AREVA). ZIRLO® is Zircaloy 4 with the addition of 0.5–1% niobium. M5™ is Zr-1% Nb with minor amounts of Fe but no Sn. M5™ has replaced Zircaloy-4 as the alloy of choice in PWRs, although Zircaloy-2 is still used in BWRs, albeit with a zirconium inner liner to protect against pellet cladding mechanical interaction–induced stress-corrosion cracking .

Moderator and coolant

The function of the moderator is to slow down the fast neutrons from energies of a few MeV to 0.025 eV. To slow down these neutrons most efficiently, the atoms of the moderator material need to have a size close to that of the neutrons. The most obvious choice is H2O, since hydrogen has the smallest atomic size. Other popular moderators are graphite, heavy water, sodium and CO2. Good moderator materials should have low neutron absorption cross-section and can also act as a coolant if the moderator material has high heat capacity to absorb the heat from the reactor, for example, water.

Reflector

Some of the neutrons leak out of the reactor core. To stop these neutrons, reflectors are used. The material properties required for the reflector are the same as that of the moderator, except that it should be solid. The common reflector materials are austenitic stainless steel, beryllium or graphite.

Top view of the WWER-1000 nuclear core. The lower support structure, the neutron reflector and 11 fuel assemblies.

Top view of the WWER-1000 nuclear core. The lower support structure, the neutron reflector and 11 fuel assemblies.

Control rod

The function of the control rod is to absorb the neutrons in the reactor. In case the neutron population increases to an uncontrollable level, then something called a reactor scram is performed, during which control rods are inserted into the reactor. Suitable materials with high neutron absorption cross-section are boron, cadmium, hafnium, etc. The control material is in the shape of blades arranged through the fuel assembly in the form of a cruciform and is generally made of B4C dispersed in 304-type stainless steel matrix or hafnium matrix .

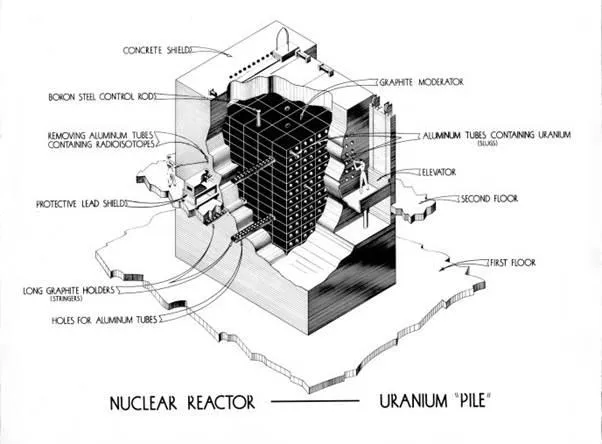

1943 Reactor diagram using boron control rods

1943 Reactor diagram using boron control rods

Reactor pressure vessel (RPV)

The RPV serves as the critical safety boundary between the reactor and the external environment and is generally considered the key lifetime-limiting (and irreplaceable) component for a nuclear reactor. The reactor pressure vessel is made up of quenched and tempered Mn-Mo-Ni low-alloy steel . These pressure vessels are very big, hence the main constraint for the material is its cost. Continuous exposure to radiation makes the RPV brittle resulting in a decrease of fracture toughness.

Ni-based alloys are used for piping and heat exchangers .

Reactor vessel installed at Ningde 3, nuclear power plant in China's Fujian province

Reactor vessel installed at Ningde 3, nuclear power plant in China's Fujian province

Conclusion

The safety of the nuclear reactor during operation can be improved significantly by continuous innovation in nuclear materials. The amount of time between the discovery of new nuclear material and implementing it to be used in a nuclear reactor is pretty large. This new material has to undergo a large amount of testing in national labs and universities before making sure that it is safe to be used in a reactor. This is important as the average lifetime of a nuclear reactor is 30-40 years and these materials need to operate for this long period of time. Failure to do so can prove costly. Hence, compared to other sectors, the innovation of materials in the nuclear sector has been rather slow.