Three

Mile Island Nuclear Accident

The Three

Mile Island Nuclear Accident was a partial core meltdown in Unit 2 (a

pressurized water reactor manufactured by Babcock & Wilcox) of the Three

Mile Island Nuclear Generating Station in Dauphin County, Pennsylvania near

Harrisburg, United States in 1979. The plant was owned and operated by General

Public Utilities and the Metropolitan Edison Co. It is the most significant

accident in the history of the American commercial nuclear power generating

industry, resulting in the release of up to 481 PBq (13 million curies) of

radioactive gases, but less than 740 GBq (20 curies) of the particularly

dangerous iodine-131.

The Three

Mile Island Nuclear Accident began at 4 a.m. on Wednesday, March 28,

1979, with failures in the non-nuclear secondary system, followed by a

stuck-open pilot-operated relief valve (PORV) in the primary system, which

allowed large amounts of nuclear reactor coolant to escape. The mechanical

failures were compounded by the initial failure of plant operators to recognize

the situation as a loss-of-coolant accident due to inadequate training and

human factors, such as human-computer interaction design oversights relating to

ambiguous control room indicators in the power plant's user interface. The

scope and complexity of the accident became clear over the course of five days,

as employees of Metropolitan Edison (Met Ed, the utility operating the plant),

Pennsylvania state officials, and members of the U.S. Nuclear Regulatory

Commission (NRC) tried to understand the problem, communicate the situation to

the press and local community, decide whether the accident required an

emergency evacuation, and ultimately end the crisis.

In

the end, the reactor was brought under control, although full details of the

accident were not discovered until much later, following extensive

investigations by both a presidential commission and the NRC. The Kemeny

Commission Report concluded that "there will either be no case of cancer

or the number of cases will be so small that it will never be possible to detect

them. The same conclusion applies to the other possible health

effects."Several epidemiological studies in the years since the accident

have supported the conclusion that radiation releases from the accident had no

perceptible effect on cancer incidence in residents near the plant, though

these findings have been contested by one team of researchers.

Public

reaction to the event was probably influenced by The China Syndrome,

a movie which had recently been released and which depicts an accident at a

nuclear reactor. Communications from officials during the initial phases of the

accident were felt to be confusing. The accident crystallized anti-nuclear

safety concerns among activists and the general public, resulted in new

regulations for the nuclear industry, and has been cited as a contributor to

the decline of new reactor construction that was already underway in the 1970s.

Three Mile Island Nuclear Accident: Stuck valve

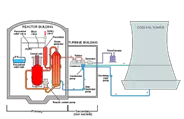

In

the nighttime hours preceding the incident, the TMI-2 reactor was running at

97% of full power, while the companion TMI-1 reactor was shut down for

refueling. The chain of events leading to the partial core meltdown began at 4

a.m. EST on March 28, 1979, in TMI-2's secondary loop, one of the three main

water/steam loops in a pressurized water reactor. As a result of mechanical or

electrical failure, the pumps in the condensate polishing system stopped

running, followed immediately by the main feedwater pumps. This automatically

triggered the turbine to shut down and the reactor to scram: control rods were

inserted into the core to control the rate of fission. But the reactor

continued to generate decay heat, and because steam was no longer being used by

the turbine due to the turbine trip, the steam generators no longer removed

that heat from the reactor.

Once

the primary feedwater pump system failed, three auxiliary pumps activated

automatically. However, because the valves had been closed for routine

maintenance, the system was unable to pump any water. The closure of these

valves was a violation of a key NRC rule, according to which the reactor must

be shut down if all auxiliary feed pumps are closed for maintenance. This

failure was later singled out by NRC officials as a key one, without which the

course of events would have been very different. The pumps were activated

manually eight minutes later, and manually deactivated between 1 and 2 hours

later, as per procedure, due to excessive vibration in the pumps.

Due

to the loss of heat removal from the primary loop and the failure of the

auxiliary system to activate, the primary side pressure began to increase,

triggering the pilot-operated relief valve (PORV) at the top of the pressurizer

to open automatically. The PORV should have closed again when the excess

pressure had been released and electric power to the solenoid of the pilot was

automatically cut, but instead the main relief valve stuck open due to a

mechanical fault. The open valve permitted coolant water to escape from the

primary system, and was the principal mechanical cause of the crisis that

followed.

Three Mile Island Nuclear Accident: Human factors – confusion

over valve status

Critical

human factors problems were revealed in the investigation about the user

interface engineering of the reactor control system's user interface. A lamp in

the control room, designed to illuminate when electric power was applied to the

solenoid that operated the pilot valve of the PORV, went out, as intended, when

the power was removed. This was incorrectly interpreted by the operators as

meaning that the main relief valve was closed, when in reality it only

indicated that power had been removed from the solenoid, not the actual

position of the pilot valve or the main relief valve. Because this indicator

was not designed to unambiguously indicate the actual position of the main

relief valve, the operators did not correctly diagnose the problem for several

hours.

The

design of the PORV indicator light was fundamentally flawed, because it implied

that the PORV was shut when it went dark. When everything was operating

correctly this was true, and the operators became habituated to rely on it.

However, when things went wrong and the main relief valve stuck open, the dark

lamp was actually misleading the operators by implying that the valve was shut.

This caused the operators considerable confusion, because the pressure,

temperature and levels in the primary circuit, so far as they could observe

them via their instruments, were not behaving as they would have done if the

PORV was shut — which they were convinced it was. This confusion contributed to

the severity of the accident: because the operators were unable to break out of

a cycle of assumptions which conflicted with what their instruments were

telling them. It was not until a fresh shift came in who did not have the

mind-set of the first set of operators that the problem was correctly

diagnosed. But by then, major damage had been done.

The

operators had not been trained to understand the ambiguous nature of the PORV

indicator and look for alternative confirmation that the main relief valve was

closed. There was a temperature indicator downstream of the PORV in the tail

pipe between the PORV and the pressurizer that could have told them the valve

was stuck open, by showing that the temperature in the tail pipe remained high

after the PORV should have, and was assumed to have, shut, but this temperature

indicator was not part of the "safety grade" suite of indicators

designed to be used after an incident, and the operators had not been trained

to use it. Its location on the back of the desk also meant that it was effectively

out of sight of the operators.

Three Mile Island Nuclear Accident: Consequences of stuck

valve

As

the pressure in the primary system continued to decrease, reactor coolant

continued to flow, but it was boiling inside the core. First, small bubbles of

steam formed and immediately collapsed, known as nucleate boiling. As the

system pressure decreased further, steam pockets began to form in the reactor

coolant. This departure from nucleate boiling caused steam voids in coolant

channels, blocking the flow of liquid coolant and greatly increasing the fuel

plate temperature. The steam voids also took up more volume than liquid water,

causing the pressurizer water level to rise even though coolant was being lost

through the open PORV. Because of the lack of a dedicated instrument to measure

the level of water in the core, operators judged the level of water in the core

solely by the level in the pressurizer. Since it was high, they assumed that

the core was properly covered with coolant, unaware that because of steam

forming in the reactor vessel, the indicator provided false readings. This was

a key contributor to the initial failure to recognize the accident as a

loss-of-coolant accident, and led operators to turn off the emergency core

cooling pumps, which had automatically started after the initial pressure

decrease, due to fears the system was being overfilled.

With

the PORV still open, the quench tank that collected the discharge from the PORV

overfilled, causing the containment building sump to fill and sound an alarm at

4:11 a.m. This alarm, along with higher than normal temperatures on the PORV

discharge line and unusually high containment building temperatures and

pressures, were clear indications that there was an ongoing loss-of-coolant

accident, but these indications were initially ignored by operators. At 4:15,

the quench tank relief diaphragm ruptured, and radioactive coolant began to

leak out into the general containment building. This radioactive coolant was

pumped from the containment building sump to an auxiliary building, outside the

main containment, until the sump pumps were stopped at 4:39 a.m.

After

almost 80 minutes of slow temperature rise, the primary loop pumps began to

cavitate as steam, rather than water, began to pass through them. The pumps

were shut down, and it was believed that natural circulation would continue the

water movement. Steam in the system prevented flow through the core, and as the

water stopped circulating it was converted to steam in increasing amounts.

About 130 minutes after the first malfunction, the top of the reactor core was

exposed and the intense heat caused a reaction to occur between the steam

forming in the reactor core and the Zircaloy nuclear fuel rod cladding,

yielding zirconium dioxide, hydrogen, and additional heat. This fiery reaction

burned off the nuclear fuel rod cladding, the hot plume of reacting steam and

zirconium damaged the fuel pellets which released more radioactivity to the

reactor coolant and produced hydrogen gas that is believed to have caused a

small explosion in the containment building later that afternoon.

At

6 a.m., there was a shift change in the control room. A new arrival noticed

that the temperature in the PORV tail pipe and the holding tanks was excessive

and used a backup valve — called a block valve — to shut off the coolant

venting via the PORV, but around 32,000 US gal (120,000 L) of coolant had

already leaked from the primary loop. It was not until 165 minutes after the

start of the problem that radiation alarms activated as contaminated water

reached detectors; by that time, the radiation levels in the primary coolant

water were around 300 times expected levels, and the plant was seriously

contaminated.

Three Mile Island Nuclear Accident: Emergency declared

At

6:56 a.m., a plant supervisor declared a site emergency, and less than half an

hour later station manager Gary Miller announced a general emergency, defined

as having the "potential for serious radiological consequences" to

the general public. Metropolitan Edison notified the Pennsylvania Emergency

Management Agency (PEMA), which in turn contacted state and local agencies,

governor Richard L. Thornburgh and lieutenant governor William Scranton III, to

whom Thornburgh assigned responsibility for collecting and reporting on

information about the accident. The uncertainty of operators at the plant was

reflected in fragmentary, ambiguous, or contradictory statements made by Met Ed

to government agencies and to the press, particularly about the possibility and

severity of off-site radiation releases. Scranton held a press conference in

which he was reassuring, yet confusing, about this possibility, stating that

though there had been a "small release of radiation,... no increase in

normal radiation levels" had been detected. These were contradicted by

another official, and by statements from Met Ed, who both claimed that no

radiation had been released. In fact, readings from instruments at the plant

and off-site detectors had detected radiation releases, albeit at levels that

were unlikely to threaten public health as long as they were temporary, and

providing that containment of the then highly contaminated reactor was

maintained.

Angry

that Met Ed had not informed them before conducting a steam venting from the plant

and convinced that the company was downplaying the severity of the accident,

state officials turned to the NRC. After receiving word of the accident from

Met Ed, the NRC had activated its emergency response headquarters in Bethesda,

Maryland and sent staff members to Three Mile Island. NRC chairman Joseph

Hendrie and commissioner Victor Gilinsky initially viewed the accident, in the

words of NRC historian Samuel Walker, as a "cause for concern but not

alarm". Gilinsky briefed reporters and members of Congress on the

situation and informed White House staff, and at 10 a.m. met with two other

commissioners. However, the NRC faced the same problems in obtaining accurate

information as the state, and was further hampered by being organizationally

ill-prepared to deal with emergencies, as it lacked a clear command structure

and the authority to tell the utility what to do, or to order an evacuation of

the local area.

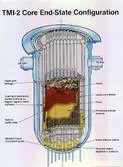

In

a 2009 article, Gilinsky wrote that it took five weeks to learn that "the

reactor operators had measured fuel temperatures near the melting point".

He further wrote: "We didn't learn for years—until the reactor vessel was

physically opened—that by the time the plant operator called the NRC at about 8

a.m., roughly one-half of the uranium fuel had already melted."

It

was still not clear to the control room staff that the primary loop water

levels were low and that over half the core was exposed. A group of workers

took manual readings from the thermocouples and obtained a sample of primary

loop water. Seven hours into the emergency, new water was pumped into the

primary loop and the backup relief valve was opened to reduce pressure so that

the loop could be filled with water. After 16 hours, the primary loop pumps

were turned on once again, and the core temperature began to fall. A large part

of the core had melted, and the system was still dangerously radioactive.

On

the third day following the accident, a hydrogen bubble was discovered in the

dome of the pressure vessel, and became the focus of concern. A hydrogen

explosion might not only breach the pressure vessel, but, depending on its

magnitude, might compromise the integrity of the containment vessel leading to

large scale release of radiation. However, it was determined that there was no

oxygen present in the pressure vessel, a prerequisite for hydrogen to burn or

explode. Immediate steps were taken to reduce the hydrogen bubble, and by the

following day it was significantly smaller. Over the next week, steam and

hydrogen were removed from the reactor using a catalytic recombiner and,

controversially, by venting straight to the atmosphere.