Details of over speed & Pneumatic over speed trip device of diesel engine

The over speed of diesel and gas engine is very severe unlike that of turbine. In case of turbine if over speed occurs, alternator can be disconnect safely by an operator while turbine can run in over speed for a while. With over speed the voltage fluctuates but that is the part of alternator which has extensive protection to handle this types of faults.

In case of diesel engine with its several number of cylinders which has moving piston and rotating crank shaft the over speed has severe impact. If over speed sustain for a long time, the engine will be mechanically damaged or break down

The over speed tolerance for diesel engines are 15% and 21% of its nominal speed. Lets say a 750 RPM engine has over speed limit 840 RPM and 880 RPM. If engine reaches 840 rpm, a shut down signal initiates but after reaching 880 RPM an immediate shut down signal is generates.

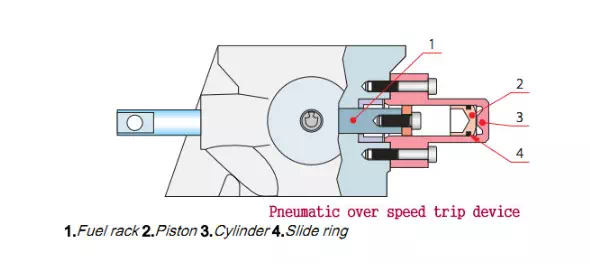

Pneumatic over speed trip device

As discussed above, over speed has high impact on Diesel engine. Thus there are lots of fail safe backup to trip the engine. In normal tripping the signal from an emergency watch circuit actuates emergency shut down circuit, but in case of over speed there is extra precautions like Pneumatic over speed trip device.

When the engine is running, the pneumatic air supply (pneumatic) with prescribed pressure to the engine must always be open.

The pneumatic over speed trip device is mounted on the multihousing and acts directly on the fuel rack. If the over speed trip device is activated, pressurized air acts on a piston in a cylinder attached to the multihousing. The piston forces the fuel rack to a “no fuel” position. The force of the over speed trip device is stronger than the torsion spring in the regulating mechanism.

Pneumatic over speed trip device

In case of Wartsila 20V32 diesel engine – The over speed trip device is electronically controlled, Air of max. 30 bar is used as operating medium. The tripping speed is 15 % above the nominal speed. The three-way solenoid valve gets the stop signal for over speed from the engine automation system.

When the solenoid valve opens, air is fed to the three-way valve, which conveys pressure air to the cylinders, one for each injection pump. The piston of the air cylinder actuates on the fuel rack moving it to stop position. The stop signal is energized long enough to stop the engine completely. When de-energized, the air is evacuated through a three-way valve.