Basic concept of diesel power plant design

The power plants all have a common thing- the alternator. Only for prime mover power plant design and layout has some huge difference. The prime mover is the mechanical drive that rotates the alternator shaft. Such as diesel engine, gas engine, boiler (steam pressure) etc.

Design of a diesel power plant:

Engine & Alternator

The first thing we need is alternator. Then to drive the alternator we need the prime mover which is in this case is a Diesel engine. The diesel engine and the alternator are set in the same frame, coupled together.

The coupling alignment, tightness must be properly ensured as this is always subject to rotational torque while engine running.

Thus both unit -engine & alternator must be attached to each other.

Diesel engine and Alternator coupled together in a same base.

Fuel supply to engine

Now we got engine, so what about the fuel to it. We need to have a reliable, continuous supply of fuel to engine. Than we need an auxiliary system to supply fuel to engine.

This fuel supply unit will consist of motor pump running by a specific pressure and heating arrangement if needed. And donít forget about the clean leak fuel re circled from the engine. As the fuel motor is running by an specific pressure continuously, the returning fuel must be store and readily supply to engine.

Lube oil supply to engine

Plus what about the continuous lube oil supply to engine. You need to ensure it, as it the most vital. This is ensured by the engine design itself. The engine has a built in lube oil pump that circulates the lube oil from its wet sump(lube oil storage in bottom of engine). But still a lube oil purification unit is needed for cost effectiveness. The lube oil purifier will continuously clean the used the lube oil.

So as discussed above the two auxiliary unit Ė fuel supply and lube oil purifier is need to be installed behind the engine.

Auxiliary Black start generator

This is a small power diesel engine to support the plant in case of black out of plant by some fault. if some fault persist or for maintenance there will be no power not from grid or from the engines, the independent auxiliary blackout generator will provide power to support the emergency unit of power plant.

As it is not used regularly, you might like to place it at a distance.

The boiler and compressor unit

The boiler provides steam to that is consumed by different unit like oil purifier or heat up the fuel if needed. Plus at stand by, the engine is need to be warm up by the recommendation from manufacturer.

The Wartsila engine is needed to be maintained at 70 degree temperature when it is in stand by mode.The compressor unit supply compressed air need for engine automation and pneumatics.

Both this units will be placed in a distant but convenient place.

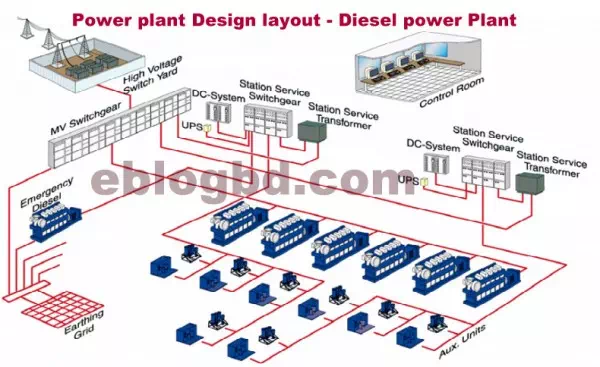

The switchgear- MV,LV, DC:

The DC unit is needed for powering the relay and other unit, A battery unit is need to preserved always for emergency backup. If power plant shut down by some means, this DC unit will support the emergency units like relays.

The low voltage switchgear is for to power the auxiliaries and plant other consumption. In general case the power consumed by low voltage is supplied from 11KV or 13.5KV MV bus by a step down transformer(11KV/440V). The alternator directly powers this 11KV bus.

The MV (medium voltage) switchgear is the SF6 circuit breaker of each alternator. This is usually placed in a panel for each alternator set. They are separated from the LV switchgear.

MV , LV switchgear will be installed and

maintained in panels

Switch yard

The High voltage switch yard is the last step in power plant. From there the power is supplied to the grid. The switch yard consist of outgoing transformer, isolator etc. It should be a restricted area, so should be placed in a convenient isolated place.