Batch Type Biogas Plant

The infeed biomass is fed in batches with large time interval between two consecutive batches. One batch of biomass infeed is given sufficient retention time in the digester (30 to 50 days). After completion of the digestion, the residue is emptied and the fresh charge is fed. The fresh biomass charge may be subjected to aeration or nitrogenation after feeding and then the digester covers are closed for the digestion process. Thereafter, the Biogas is derived from the digester after 10 to 15 days. Fermentation continues for 30 to 50 days.

Salient Features:

1. Batch type biogas plant delivers gas intermittently and dis-continuously.

2. Batch type biogas plant may have several digesters (reacters) which are fed in a sequential manner and discharged in a sequential manner to obtain the output biogas continuously.

3. Batch type biogas plants have longer digestion time and are therefore more suitable for materials which are difficult for anaerobic digestion (e.g. harder, fibrous biomass).

4. Batch type biogas plant needs initial seeding to start the anaerobic fermentation.

5. Batch type biogas plant needs larger volume of the digester to accommodate large volume of the batch. Hence initial cost is higher.

6. Operation and maintenance is relatively more complex. Batch type biomass plants need well organised and planned feeding. Such plants are preferred by European farmers. Such plants are not yet popular in India.

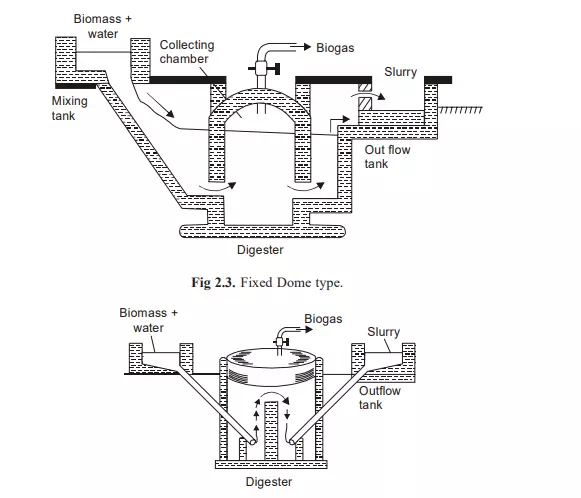

Fixed Dome Type Digester

In the fixed dome type digester biogas plant, the digester and gas-collector (gas dome) are enclosed in the same chamber. This type of construction is suitable for batch type biogas plant. The digester is conveniently built at or below ground level in comparatively cooler zone. The construction of the digester is with locally available materials like, bricks, tera-cota. The pressure inside the digester increases as the biogas is liberated. The biogas gets collected in the upper portion of the digester in a dome shaped cavity. The outlet pipe is provided at the tope of the fixed dome. Alternatively the gas collector (gas holder) is a separately installed chamber. The digester tank and gas collector chamber are separated by a water seal tank.

The arrangement of a separate gas collector is preferred as the tapping of gas from the gas holder does not affect the pressure and the digestion process in the main digester. The water seal tank prevents the return of the gas from the gas collector to the digester chamber.

An additional displacement chamber may be provided for provid-ing space to the displacement slurry in the digester due to gas pressure in the upper dome of the fixed type digester. The fixed dome type digester can be fed on daily basis with small quantities of the slurry. The excess slurry in the digester gets accommodated in the displacement chamber. The level of the slurry in the main digester and the displacement collector can vary in accordance with the pressure and volume of the biogas in the fixed type of dome. The pressure in the fixed dome and the displacement gas collector are almost the same as they are connected by the outlet from the main digester.

Floating gas holder type.

Floating Gas Holder Type. In this design a dome made floats above the slurry in the disaster. In the Fig, The disaster tank is of cylindrical masonry construction. The floating dome is of fabricated steel construction. The dome guide shaft provides the axial guide to the floating dome. As the gas is collected in it. The sliding bearing provides smooth sliding surface and guide to the floating dome. The gas generated in the slurry gets collected in the dome and the dome arises. The water seal tank provides separation between the gas in the dome and the outlet gas.