Lever safety

valve

The advantage of level safety

valve over the dead weight safety valve is that the heavy dead weight is

replaced by a lever with a smaller weight.

Description of Lever safety valve:

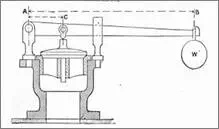

It consists of a valve resting over a

gun metal seat. The valve seat is fixed on a mounting block, fitted over the

boiler shell. One end of the level is hinged to a rod of the mounting block,

while the other end carries a weight. A short strut is placed over the valve.

It consists of a valve resting over a

gun metal seat. The valve seat is fixed on a mounting block, fitted over the

boiler shell. One end of the level is hinged to a rod of the mounting block,

while the other end carries a weight. A short strut is placed over the valve.

Working of Lever safety valve:

The thrust of the lever with

its weight is transmitted to the valve by the strut. When the steam pressure

exceeds the safe limit, the upward thrust of steam lifts the valve from its

seat and the lever with its weight. The excess steam escapes till the pressure

falls back to the normal value. The valve then returns back to its original

closed position.

The required weight W at the

end of the lever for maintaining the pressure P in the boiler is obtained by

taking moments about the hinged point.

i.e., PaL1 = WL2

Where a = area of the valve

exposed to steam,

L1 = distance of valve centre

from the hinged point, and

L2 = distance of the centre

of the weight to the hinged point.

The lever safety valve is

used in stationary boilers only.