PRINCIPLE

OF CIRCULATION

1. Principles of Circulation

Subcooled FW enters the drum,

mixes with the circulating boiler water, and attains saturation temperature

instantly, as the boiling, circulating water is several times the incoming

water flow.

This circulating water picks

up its latent heat progressively from the hot flue gases to form steam as it

goes around the evaporator circuits several times. This steam is continuously

separated in the drum by the steam separators. There is a balance between the

incoming feed water (FW) and the outgoing steam when the system is properly

functioning.

Circulation ratio is the

water in circulation divided by the steam flow.

In other words it is the number of times the water has to go around the various

evaporator circuits before it is all converted into steam. Latent heat is added

to the circulating water at constant pressure and constant temperature.

There is no circulation in SC

boilers as it is a forced fl ow

arrangement. In once-through (OT) subcritical boilers also there is no

circulation. To take advantage of the relatively low boiling temperature of

water (critical temperature is 374.1°C), the hottest portion of the boiler,

namely, the furnace, is encased in tubes carrying boiling, circulating water. The

screen, division wall, boiler bank (BB), and EVAP tubes also form parts of the

circulating system.

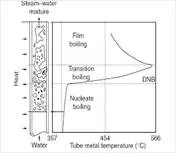

It therefore follows that the

most important use of circulating water is extracting high amounts of heat,

particularly in the furnace, to keep the tubes cool. This is only possible as

long as the steam bubble formation on the inside of tubes does not give way to

a film of steam. In other words the departure from nucleate boiling (DNB) does

not set in.

It is important to remember

that a boiler is not designed for circulation, but for cooling the gases with

ECON, evaporator, SH, and RH surfaces. It is then checked for circulation.

Adequacy of circulation to

prevent DNB is vital in all conditions of operation—at all loads with all fuels

and combinations. It means that the velocities of steam–water mixture at all

points are high enough to keep the tubes wet with no DNB. This is the essence

of circulation requirement, and circulation check should be performed to verify

that this condition is fully met. Usually, changes to the supply and riser tube

geometry that feed and collect the water–steam mixtures, respectively, in the

various circuits are needed to remedy the defi ciencies. At times, other measures such as fitting of

ferrules, using ribbed/rifled tubes, and so on may also be needed.

2. Flow in Vertical and

Horizontal Tubes

2. Flow in Vertical and

Horizontal Tubes

1. Tube A is bubble fl ow with low velocity and a few steam bubbles in a

predominant

water flow.

2. Tube B is emulsion fl ow where the steam bubbles increase and hence

produce froth.

3. Tube C is slug fl ow with fi ne bubbles coalescing to form big

bubbles almost fi lling the bore of the

tube.

4. Tube D is wet wall fl ow where the steam fi lls the

tube with an annular fi lm of water cooling the tube.

5. Tube E is dry wall fl ow where the water fi lm is replaced by a thin

steam film that has poor cooling ability.

In a horizontal tube

the fl ow patterns are different. Owing to

the density difference, all the steam bubbles migrate to the top of the tube

and slide along the tube wall.

1. At higher velocities (Tube

A) of >1 m/s, the steam bubbles join together and move

along with water, resembling wet

water fl ow.

2. At low velocities (Tube B)

of <0.5>250,000 kcal/m2 h or 92,000 Btu/ft2 h) cannot be avoided,

particularly in the burner zone. There is a limit to increasing the velocities

at (higher) pressures >150 bar when the circulation ratios are on the lower

side.

Ribbed or rifl ed tubes are

helpful in delaying the onset of DNB when compared to smooth tubes, as they

offer more wetted surface for adherence of water film. The permissible steam by

weight percentage (%SBW) for the same heat flux is raised from a range of

20–40% level to a range of 70–90% level by the use of ribbed tubes. Since they

are expensive, they are employed around the burner zone and mainly in high

pressure and SC boilers.

To maintain wet wall flow or

nucleate boiling under all conditions, the following criteria must be satisfi ed for each

circuit. A circuit is a set of heated tubes of similar shape and heat input

that allow upward fl ow of water.

1. Exit quality. SBW at the

top of any circuit should be less than aspecifi ed limit depending on the drum pressure and the

location of burners—whether at the top or bottom—to prevent film boiling at the

top of the circuit.

2. Minimum velocity. Water

velocity at the commencement of the circuit should exceed

a specifi ed limit, depending on the inclination of the tubes to

prevent the steam bubbles from adhering to the tube walls, causing overheating,

and also to prevent sludge accumulation.

3. Saturated water head

(SWH). The SWH, the ratio of pressure loss (including static head) to the

pressure produced by a column of saturated water of the same height, is

required to be at a certain specifi ed minimum to prevent fl ow

reversal. The usual remedy for meeting this requirement is to increase the

water fl ow to the defaulting circuit.