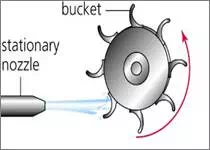

Impulse Turbine

Description of impulse turbine:

Wheel or Rotor

:

The wheel or rotor is fitted over a shaft

from which the useful power is available. It is a rotating element of the

turbine on which moving blades are fixed.

Nozzle:

The nozzle is a passage for the flow of

steam where pressure energy is converted into kinetic energy. Its main function

is to produce a jet of steam with a high velocity.

Blades :

De Laval turbine shown in the image below

is an example of simple impulse turbine.

In this, only one set of impulse type

blades is rigidly fixed to the rim of the rotor or wheel. It converts the

kinetic energy of steam into mechanical work.

Casing :

The casing is the outside cover of the

steam turbine fixed over a frame. It is fitted with nozzle.

Working Principle of Impulse turbine :

If a jet of steam is discharged from a

fixed nozzle at a high speed over a flat stationary plate, a steady force will

be exerted over this plate. This force is nothing but an impulse. No work is

done as the plate is fixed. But, if a number of such plates are fixed on the

rim of a wheel, the wheel may be rotated due to the impulse of steam. Curved

plates are used instead of flat plates to utilize greater amount of energy.

In the impulse turbine, steam is expanded

in the fixed nozzle only. In the nozzle the velocity of steam increases with

decrease of pressure. As the steam passes over the blades, the pressure remains

constant with a decrease of velocity.

As the high velocity steam impinges against

the baldes, it changes the momentum of jet

causing impulsive force on the blades. The wheel is thus made to rotate in a

definite direction.

Here the kinetic energy is converted into

mechanical work, only by one set of blades. It is simplest type of impulse

turbine.