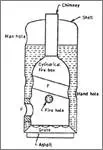

Simple vertical boiler

The image shows the simplest form of an

internally fired vertical fire-tube boiler. It does not require heavy

foundation and requires very small floor area.

Cylindrical shell:

The shell is vertical and it attached to

the bottom of the furnace. Greater portion of the shell is full of water which

surrounds the furnace also. Remaining portion is steam space. The shell may be

of about 1.25 metres diameter and 2.0 meters height.

Cross-tubes:

One or more cross tubes are either riveted

or flanged to the furnace to increase the heating surface and to improve the

water circulation.

Furnace (or fire box):

Combustion of coal takes place in the

furnace (fire box).

Grate:

It is placed at the bottom of fire box and

coal is fed on it for burning.

Fire door:

Coal is fed to the grate through the fire

door.

Chimney (or stack):

The chimney (stack) passes from the top of

the firebox through the top of the shell.

Manhole:

It is provided on the top of the shell to

enable a man to enter into it and inspect and repair the boiler from inside it.

It is also, meant for cleaning the interior of the boiler shell and exterior of

thecompbustion chamber and stack (chimney).

Hand holes:

These are provided in the shell opposite to

the ends of each cross tube for cleaning the cross tube.

Ashipt:

It is provide for collecting the ash

deposit, which can be removed away at intervals.

Working:

The fuel (coal) is fed into the grate

through the fire hole and is burnt. The ashpit placed

below the grate collect the ashes of the burning fuel.

The combustion gas flows from the furnace,

passes around the cross tubes and escapes to the atmosphere through the chimney.

Water goes by natural circulation due to

convection currents, from the lower end of the cross tube and comes out from

the higher end.

The working pressure of the simple vertical

boiler does not exceed 70 N/cm^2.

The

following mountings are fitted in the boiler:

Pressure gauge: it indicates the pressure of the steam inside

the boiler.

Water gauge (water level

indicator): this indicates the

water level in the boiler.

Safety valve: it prevents an increase of steam pressure intheboiler above its design pressure.

Steam stop valve: it

regulates the flow of steam supply to requirements.