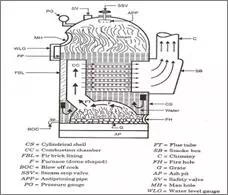

Cochran boiler

It is a multi-tubular vertical fire tube

boiler having a number of horizontal fire tubes. T is the modification of a

simple vertical boiler where the heating surface has been increased by means of

a number of fire tubes.

It consists of

1. Shell

2. Crate

3. Fire box

4. Flue pipe

5. Fire tubes

6. Combustion chamber

7. Chimney

8. Man-hole

Shell

It is hemispherical on the top, where space

is provided for steam.

Grate

It is placed at the bottom of the furnace

where coal is burnt.

Fire box (furnace )

It is also dome-shaped like the shell so

that the gases can be deflected back till they are passed out through the flue

pipe to the combustion chamber.

Flue pipe:

It is a short passage connecting the fire

box with the combustion chamber.

Fire tubes:

A number of horizontal fire tubes are

provided, thereby the heating surface is increased.

Combustion chamber:

It is lined with fire bricks on the side of

the shell to prevent overheating of the boiler. Hot gases enter the fire tubes

from the flue pipe through the combustion chamber.

Chimney:

It is provided for the exit of the flue

gases to the atmosphere from the smoke box.

Manhole:

It is provided for inspection and repair of

the interior of the boiler shell.

Normal size of a Cochran boiler:

Shell diameter – 2.75 meters:

Height of the shell – 6 meters.

Working of the Cochran boiler:

Coal is fed into the grate through the fire

hole and burnt. Ash formed during burning is collected in the ashpit provided just below the grate and then it is

removed manually.

The host gases from the grate pass through

the flue pipe to the combustion chamber. The hot gases from the combustion

chamber flow through the horizontal fire tubes and transfer the heat to the

water by convection.

The flue gases coming out of fire tubes

pass through the smoke box and are exhausted to the atmosphere through the

chimney.

Smoke box is provided with a door for

cleaning the fire tubes and smoke box.

The following mountings are fitted to

the boiler:

Pressure gauge: this indicates the pressure of the steam inside the

boiler.

Water gauge: this indicates the water level in the boiler. The

water level in the boiler should not fall below a particular level, otherwise

the boiler will be over heated and the tubes may burn out.

Safety valve: the function of the safety valve is to prevent an

increase of steam pressure in the boiler above its normal working pressure.

Steam stop valve: it regulates the flow of steam supply to

requirements.

Blow-off cock: it is located at the bottom of the boiler. When the

blow-off cock is opened during the running of the boiler, the high pressure

steam pushes (drains) out the impurities like mud, sand, etc., in the water

collected at the bottom.

Fusible plug: it protects the fire tubes from burning when the

water level in the boiler falls abnormally low.

Salient features of Cochran boiler:

1. The dome shape of the furnace causes the hot gases to

deflect back and pass through the flue. The un-burnt fuel if any will also be

deflected back.

2. Spherical shape of the top of the shell and the fire

box gives higher area by volume ratio.

3. It occupies comparatively less floor area and is very

compact.

4. It is well suited for small capacity requirements.