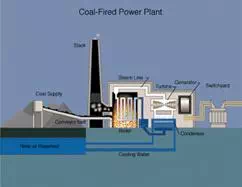

Coal Power Plant Schematic

Diagram

Generation of electricity in

a coal-fired steam station is similar to a nuclear station. The difference is

the source of heat. The burning of coal replaces fissioning,

or splitting , of uranium atoms as the

source of heat. The heat turns water to steam in steam generators. The steam is

then used to drive turbine generators.

1. Firebox

Before the coal is burned, it

is pulverized to the fineness of talcum powder. It is then mixed with hot air

and blown into the firebox of the boiler. Burning in suspension, the coal-air

mixture provides the most complete combustion and maximum heat possible.

2. Boiler

Highly purified water, pumped

through pipes inside the boiler, is turned into steam by the heat. At

temperatures of up to 1,000 degrees Fahrenheit and under pressures up to 3,500

pounds per square inch, the steam is piped to the turbine.

3. Turbine|Generator

The enormous pressure of the

steam pushing against a series of giant turbine blades turns the turbine shaft.

The turbine shaft is connected to the shaft of the generator, where magnets

spin within wire coils to produce electricity.

4. Condenser

After doing its work in the

turbine, the steam is drawn into a condenser, a large chamber in the basement

of the power plant. The condenser is an important part of a steam-electric

unit, whether nuclear or coal-fired. This device condenses the steam leaving

the turbines back into water so that it can be used over and over again in the

plant. This essential cooling process requires large quantities of water; thus,

most steam-electric stations are located on lakes or rivers.

5. Condenser Cooling Water

Millions of gallons of cool

lake water are pumped through a network of tubes that runs through the

condenser. The water in the tubes cools the steam and converts it back into

water. After the steam is condensed, it is pumped to the boiler again to repeat

the cycle.

Coal Fired Power Plant Schematic Diagram: