The Prozyr Femoral Ball Recall

In 2001, in European and American regulatory agencies recalled millions  of zirconia ball heads sold under the commercial name Prozyr by Saint Gobain Ceramiques Desmarquest. These heads are one of the important components used in a total hip replacement procedures also known as arthroplasty. This recall happened because the femoral ball heads were fracturing and failing at inordinately high rate after implantation in patients in a relatively short period of time. What followed was an intense international investigation by a panel of experts. The company and regulatory agencies wanted to find out answers to two central questions as soon as possible. What caused these fractures that led to the failure of these implants? What changed that caused this sudden jump in failure rates?

of zirconia ball heads sold under the commercial name Prozyr by Saint Gobain Ceramiques Desmarquest. These heads are one of the important components used in a total hip replacement procedures also known as arthroplasty. This recall happened because the femoral ball heads were fracturing and failing at inordinately high rate after implantation in patients in a relatively short period of time. What followed was an intense international investigation by a panel of experts. The company and regulatory agencies wanted to find out answers to two central questions as soon as possible. What caused these fractures that led to the failure of these implants? What changed that caused this sudden jump in failure rates?

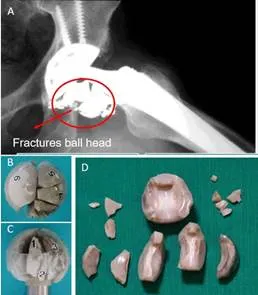

Image A is an X-ray of the fractured implant. The shattered ball head is marked by the red circle. Image B and C show are photographs that show the top and side views of the fractured parts collected and reassembled into the femoral ball. Image D is a photograph of the Zirconia ceramic fragments collected from implant retrieved from a patient.

Image A is an X-ray of the fractured implant. The shattered ball head is marked by the red circle. Image B and C show are photographs that show the top and side views of the fractured parts collected and reassembled into the femoral ball. Image D is a photograph of the Zirconia ceramic fragments collected from implant retrieved from a patient.

The Zirconia femoral heads spontaneously fractured (see right figure for an example) within 27 months after implantation. Their expected lifespan after implantation is at least 10 years. Subsequent investigation also found that six batches manufactured after 1998 had fracture issues and two batches had major failure rates (as high as 1 in 3 balls for one batch). Typically the failure of hip implants is around 1 in 10,000 units. Indeed, till 1998 thousands of hip implants with Prozyr femoral balls showed very low failure rates.

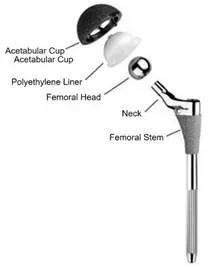

To appreciate the significance of the problem, you will need to know the significance of the femoral ball in a total hip replacement. Please read this blog for a primer on total hip arthroplasty. This blog also provides more background on where a femoral ball fits in a total hip replacement surgery.

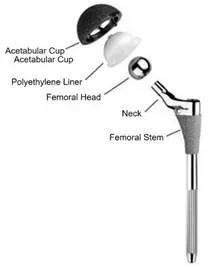

The right figure shows the various components of THA implant. The problem occurred with the femoral head which was made of the ceramic material zirconia – an oxide of the element Zirconium. Zirconia was getting popular as an alternative to another ceramic Alumina (oxide of the element Aluminium) since it showed good mechanical properties (toughness and strength) capable of withstanding wear down from the constant friction with the polyethylene liner/insert which is found in the acetabular cup. Most of the Zirconia femoral ball failures before the current problem were linked to high wear of the polyethylene liner which sometimes also lead to degradation of the Zirconia surface. The wear debris accumulates near the implant to cause local inflammation and bone loss. This condition is called osteolysis, and can and loosen the implant leading to failure. However, the investigators quickly ruled out high wear rate as the cause since the implant surface did not show any evidence of roughness which would have implied increase wear rate.

problem occurred with the femoral head which was made of the ceramic material zirconia – an oxide of the element Zirconium. Zirconia was getting popular as an alternative to another ceramic Alumina (oxide of the element Aluminium) since it showed good mechanical properties (toughness and strength) capable of withstanding wear down from the constant friction with the polyethylene liner/insert which is found in the acetabular cup. Most of the Zirconia femoral ball failures before the current problem were linked to high wear of the polyethylene liner which sometimes also lead to degradation of the Zirconia surface. The wear debris accumulates near the implant to cause local inflammation and bone loss. This condition is called osteolysis, and can and loosen the implant leading to failure. However, the investigators quickly ruled out high wear rate as the cause since the implant surface did not show any evidence of roughness which would have implied increase wear rate.

Thorough analysis showed that the inner core of the ball was not as dense as necessary. Consequently, a crack that started near the ball and neck boundary quickly propagated into a fracture into this inner less compact core. The wet environment because of biological fluids under cyclic loading hastened the process. Phase change in the Zirconia structure was also shown as another reason for fracture propagation. Zirconia is considered metastable ceramic, i.e., it is considered generally stable but can lose stability under certain conditions. One the conditions when it can lose its stability in under contact with water. At room temperature, it can be transformed under interaction with water from tetragonal crystal structure to monoclinic crystal structure also known as tetragonal-to-monoclinic transition. The monoclinic structure is more brittle and susceptible to failure. Manufacturers typically add a small amount of small of Yttria (oxide of the element Yttrium) to stabilize Zirconia in the tetragonal crystal phase. But in this case, water was able to perfuse through Zirconia and cause the phase change.

Finally, it was revealed that change in the manufacturing process as the reason for the sudden increase in Prozyr failure rates. In 1998, Saint Gobain Ceramiques Desmarquest changed the processing step to sinter the zirconia balls to a batch furnace (right top figure) from a continuous flow tunnel furnace (right middle figure). During sintering, the Zirconia powder is bound together into a solid implant by heating it and typically also compressing it. The powder is not liquefied. The bottom right figure shows the temperature profiles of these two furnaces while sintering zirconia. The batch furnace sintering conditions were found to be inadequate to fully densify the center of the ball. This unstable part was exposed which the balls were drilled to attach them to the femoral stem.

for the sudden increase in Prozyr failure rates. In 1998, Saint Gobain Ceramiques Desmarquest changed the processing step to sinter the zirconia balls to a batch furnace (right top figure) from a continuous flow tunnel furnace (right middle figure). During sintering, the Zirconia powder is bound together into a solid implant by heating it and typically also compressing it. The powder is not liquefied. The bottom right figure shows the temperature profiles of these two furnaces while sintering zirconia. The batch furnace sintering conditions were found to be inadequate to fully densify the center of the ball. This unstable part was exposed which the balls were drilled to attach them to the femoral stem.

The outcome of the investigation led to the company’s decision to pull Prozyr off the market. It also led to questions about the future of Zirconia as a biomaterial.

of zirconia ball heads sold under the commercial name Prozyr by Saint Gobain Ceramiques Desmarquest. These heads are one of the important components used in a total hip replacement procedures also known as arthroplasty. This recall happened because the femoral ball heads were fracturing and failing at inordinately high rate after implantation in patients in a relatively short period of time. What followed was an intense international investigation by a panel of experts. The company and regulatory agencies wanted to find out answers to two central questions as soon as possible. What caused these fractures that led to the failure of these implants? What changed that caused this sudden jump in failure rates?

of zirconia ball heads sold under the commercial name Prozyr by Saint Gobain Ceramiques Desmarquest. These heads are one of the important components used in a total hip replacement procedures also known as arthroplasty. This recall happened because the femoral ball heads were fracturing and failing at inordinately high rate after implantation in patients in a relatively short period of time. What followed was an intense international investigation by a panel of experts. The company and regulatory agencies wanted to find out answers to two central questions as soon as possible. What caused these fractures that led to the failure of these implants? What changed that caused this sudden jump in failure rates? problem occurred with the femoral head which was made of the ceramic material zirconia – an oxide of the element Zirconium. Zirconia was getting popular as an alternative to another ceramic Alumina (oxide of the element Aluminium) since it showed good mechanical properties (toughness and strength) capable of withstanding wear down from the constant friction with the polyethylene liner/insert which is found in the acetabular cup. Most of the Zirconia femoral ball failures before the current problem were linked to high wear of the polyethylene liner which sometimes also lead to degradation of the Zirconia surface. The wear debris accumulates near the implant to cause local inflammation and bone loss. This condition is called osteolysis, and can and loosen the implant leading to failure. However, the investigators quickly ruled out high wear rate as the cause since the implant surface did not show any evidence of roughness which would have implied increase wear rate.

problem occurred with the femoral head which was made of the ceramic material zirconia – an oxide of the element Zirconium. Zirconia was getting popular as an alternative to another ceramic Alumina (oxide of the element Aluminium) since it showed good mechanical properties (toughness and strength) capable of withstanding wear down from the constant friction with the polyethylene liner/insert which is found in the acetabular cup. Most of the Zirconia femoral ball failures before the current problem were linked to high wear of the polyethylene liner which sometimes also lead to degradation of the Zirconia surface. The wear debris accumulates near the implant to cause local inflammation and bone loss. This condition is called osteolysis, and can and loosen the implant leading to failure. However, the investigators quickly ruled out high wear rate as the cause since the implant surface did not show any evidence of roughness which would have implied increase wear rate. for the sudden increase in Prozyr failure rates. In 1998, Saint Gobain Ceramiques Desmarquest changed the processing step to sinter the zirconia balls to a batch furnace (right top figure) from a continuous flow tunnel furnace (right middle figure). During sintering, the Zirconia powder is bound together into a solid implant by heating it and typically also compressing it. The powder is not liquefied. The bottom right figure shows the temperature profiles of these two furnaces while sintering zirconia. The batch furnace sintering conditions were found to be inadequate to fully densify the center of the ball. This unstable part was exposed which the balls were drilled to attach them to the femoral stem.

for the sudden increase in Prozyr failure rates. In 1998, Saint Gobain Ceramiques Desmarquest changed the processing step to sinter the zirconia balls to a batch furnace (right top figure) from a continuous flow tunnel furnace (right middle figure). During sintering, the Zirconia powder is bound together into a solid implant by heating it and typically also compressing it. The powder is not liquefied. The bottom right figure shows the temperature profiles of these two furnaces while sintering zirconia. The batch furnace sintering conditions were found to be inadequate to fully densify the center of the ball. This unstable part was exposed which the balls were drilled to attach them to the femoral stem.