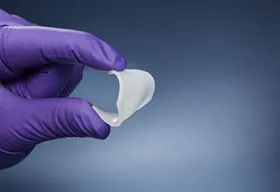

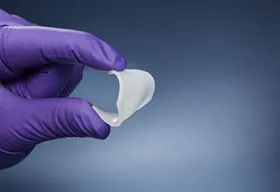

The new rubber-like material developed by researchers at Chalmers University of Technology is highly flexible.

The new rubber-like material developed by researchers at Chalmers University of Technology is highly flexible. The new rubber-like material developed by researchers at Chalmers University of Technology is highly flexible.

The new rubber-like material developed by researchers at Chalmers University of Technology is highly flexible.

In the development of medical technology products, there is a great demand for new naturalistic materials suitable for integration in the body. This is because introducing materials into the body comes with many risks, including serious infections. Many of the substances used today, such as Botox, are very toxic. There is thus a need for new, more adaptable materials.

In this new study, the Chalmers researchers developed a material consisting solely of components that have already been shown to work well in the body.

The foundation of the material is plexiglass, a material that is commonly used in medical technology applications. By redesigning its makeup, and taking advantage of a process called nanostructuring, the researchers were able to give the newly patented material a unique combination of properties.

Their initial intention was to produce a hard bone-like material, but they were met with surprising results. "We were really surprised that the material turned out to be very soft, flexible and extremely elastic. It would not work as a bone replacement material, we concluded. But the new and unexpected properties made our discovery just as exciting," says Anand Kumar Rajasekharan, one of the researchers behind the study.

The results showed that the new rubber-like material may be appropriate for many applications that require an uncommon combination of properties – high elasticity, easy processability and suitability for medical uses.

"The first application we are looking at now is urinary catheters. The material can be constructed in such a way that prevents bacteria from growing on the surface, meaning it is very well suited for medical uses," says Martin Andersson, research leader for the study and professor of chemistry at Chalmers.

The structure of the new nano-rubber material allows its surface to be treated so that it becomes antibacterial, in a natural, non-toxic way. This is achieved by sticking antimicrobial peptides – small proteins that are part of our innate immune system – onto its surface. These peptides can help reduce the need for antibiotics, an important contribution in the fight against growing antibiotic resistance.

Because the new material can be injected and inserted via keyhole surgery, it can also help reduce the need for drastic surgery and operations to rebuild parts of the body. The material can be injected via a standard cannula as a viscous fluid, so that it forms its own elastic structures within the body. Alternatively, the material can be 3D printed into specific structures as required.

"There are many diseases where the cartilage breaks down and friction results between bones, causing great pain for the affected person. This material could potentially act as a replacement in those cases," Andersson adds.

A further advantage of the material is that it contains three-dimensionally ordered nanopores, allowing it to be loaded with medicine for various therapeutic purposes such as improving healing and reducing inflammation. This means it can be used for localized treatment, thereby avoiding, for example, having to treat the entire body with drugs, which can help reduce problems associated with side effects. Since it is non-toxic, the material also works well as a filler – the researchers see plastic surgery as another very interesting potential area of application.

In order for the discovery of the new material to be useful and commercialized, the researchers patented their innovation before the paper was published. The patent is owned by start-up company Amferia, which was founded by Andersson and Rajasekharan, as well as researcher Saba Atefyekta who recently completed a PhD in materials science at Chalmers. Anand is now CEO of Amferia, and will drive the application of the new material and development of the company.