Steam Blowing Stages Part-III (Boiler Commissioning) Abc Of Thermal Power Plant

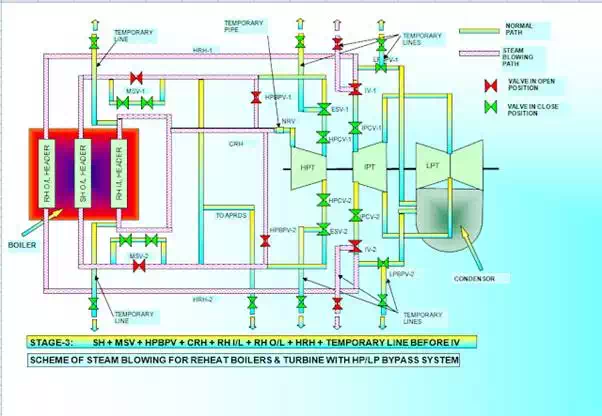

Stage 3a -- Steam inlet line from COLD RE HEAT to TURBINE DRIVEN BOILER FEED PUMP A ESV. Steam valve of PRDS line will be kept closed. Electro hydraulic control valve will not be erected and steam blowing arrangement (Blanking device) shall be used. This stage shall be concluded by observing the indents on target plates.

Stage 3b -- Steam inlet line from CRH to TDBFP B ESV. Steam valve of PRDS line will be kept closed. Electro hydraulic control valve will not be erected and steam blowing arrangement (Blanking device) shall be used. This stage shall be concluded by observing the indents on target plates.

Operation during Stage 3a & 3b

Boiler is lighted up and Separator pressure raised to 20 Kg/cm2 and steam lines charged from Boiler outlet up to dummies provided in the temporary piping of stages 2a and 2b. (Alternatively, after restoration of ESV, IV, HPBP, LPBP, 3a & 3b stages blowing can be taken up at a later date prior to commg of TDBFP turbine)

Temporary steam valve or Dummy provided in the Temporary exhaust lines connected to permanent steam lines to TDBFPs is kept open.

CRH-1 & CRH-3 are gradually opened to full. Steam blowing is carried out for 20-30 minutes at about 50% of system operating pressure. Blowing is continued with a gap of two hours between the blows.

After few blows, Target Plates are put and further blowing continued. Termination of stage 3a and 3b are as per Target plate results as given in Section 9.0.

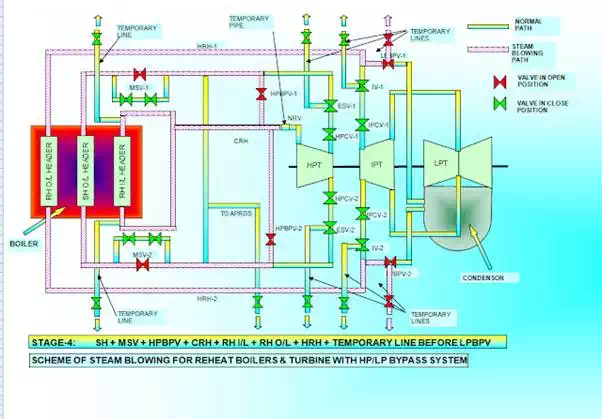

Stage 4 -- Auxiliary Steam Lines

4a – From PRDS to TDBFP A ESV

4b --From PRDS to TDBFP B ESV

4c -- From CRH to Turbine extraction lines

4d -- From CRH to extraction line to Deaerator

4e -- From CRH to Deaerator / FST

4f -- From CRH to HP Heaters

4g -- From CRH to Turbine gland sealing header

4h -- From CRH to PRDS to Aux Steam Header

4i -- From Main Steam line to PRDS to Aux Steam Header

Steam blowing of sub-stages 4h & 4i shall be done prior to blowing of sub-stages 4a & 4b.

Operation Stage 4

Temporary steam valve or Dummy provided in the Temporary exhaust line connected to permanent steam line to BFP Turbine is kept open.

Steam blowing for sub-stages 4a & 4b is carried out for 20-30 minutes. Blowing is continued with a gap of two hours between the blows.

After few blows, Target Plates are put and further blowing continued. Termination of stage 4a and 4b are as per Target plate results as given in Section 9.0.

Minimum three nos. of blows are given for each of sub stag 4c to 4i. Blows are given at intervals of one hour.