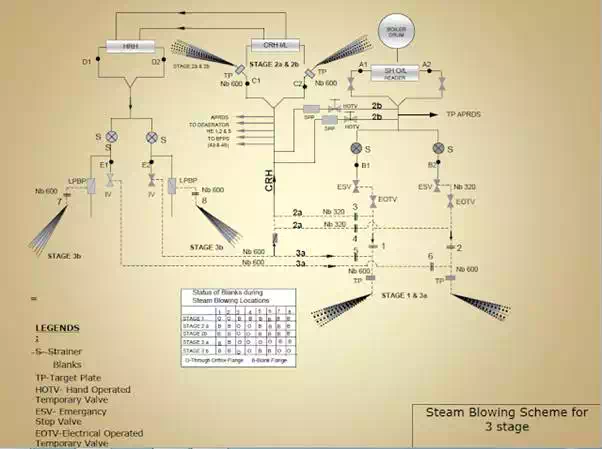

Concluding Part Steam Blowing Part -Iv Abc Of Thermal Power Plant

For the first few blows Target plates need not be kept. Afterwards Target plates made of Stainless steel of mirror finish are to be used.

Target plates are mounted in the temporary exhaust pipes nearer to the permanent line.

Steam blowing can be declared complete only after ensuring cleanliness of target plates. Following criteria is followed for declaring completion of steam blowing:

Stage 1c & 2b

Minimum 8 (eight) numbers of blows are to be given.

Stages 4c to 4i

Steam blowing is declared complete based on visual observation. Minimum three nos. of blows shall be given for each sub stage.

No of impact >= 1 mm

Less than 4 impacts >= 0.5mm

less than 10 impacts >= 0.2mm

Total impact above 2mm size not exceeding 10 nos at the end of steam blow.

Impacts below 0.2mm size at the end of steam blow can be accepted provided they are well dispersed and uniform in distribution without creating a rough surface.

Minimum number of consequtive target plate is two.

The above criteria has been fixed by BHEL for 660 MW Boiler. However there are difference of opinion regarding completion criteria. The First difference of opinion arises on metal of target plate. Earlier days we have seen use of bronze target plate and it is malleable material therefore slightest impacts are visible. Therefore steam blowing operation gets continued longer time and disturbance factor calculation was not available with us. For any 200 to 250MW plant steam blowing operation took around 30 to 40 days. After that target plate changed to Mild steel and now stainless steel. As per CEA guidelines it is written as steel. Therefore all personnel carrying out steam blowing should agree with the material.

A Few points to be noted during steam blowing :

1. Four number Electrical operated trip valves with quick opening and closing are needed to conduct steam blowing. To standardize the requirements 12”/1500 class for 250 MW and below and 14”/1500 class for 500MW and above are selected. Material of valve body selected is WC9.

2. Special precaution to be taken in cleaning of CRH lines . As it is seen that Reheater tube failures happened due to debris deposited in reheater tubes. Lines are to be checked thoroughly and some time it may happen a small portion of pipe not cleaned during steam blowing operation. Therefore pre cleaning and to maintain a log on that is necessary to avoid complication at later dates.

3. The steam blowing operation produces tremendous noise and certainly does noise pollution to the maximum effect. In earlier days people are not bothered about such pollution but now all are aware therefore steps to be taken to reuce this noise pollution . Earlier days only ear caps were provided but now a days silencer has been designed to reduce the noise.

The Steam Blowing Silencers are used to reduce the noise produced by the valve (Structure born noise and Air born noise) , when venting of pressurized and high velocity gas to the atmosphere, especially , steam, air and nitrogen.

4. The low point drain will be getting chocked at the time of initial operation. Therefore the same to be cut and debris to be cleared immediately and again re –weld the same after ensuring that steam flows through the drain.

5. Tools and other materials should be kept ready for cleaning of BFP and CEP strainers. As initially there will be frequent choking of strainer one after another

with minimum time gap. If you are not prepared you can not keep the boiler running.

6. As we will running the boiler through oil firing then Air heater soot blower is must.

7. Drum level should be on manual to take care of swelling during blow off.

Disturbance Factor = Qb2 x Vb

![]() or

or

clearing force ratio Q2 MCR x VMCR

Qb - Steam flow during blowing

QMCR - Steam flow at MCR

Vb - Sp. Volume of steam during blowing

VMCR - Sp. Volume of steam at MCR

Qb = 1.13 x A x sq.rt of P/V

A = Area of Blow out pipe at the end ( cm2)

P= Pressure at blow at blow out piping end.

V= steam specific volume at blow out piping end.