Control And Instrumentation Of Thermal Power Station

There are four instruments generally used any process plant as basic instrument since invent of such instruments. Therefore basic specification is given below for procuring instrument at site if required. The instruments are Pressure gauge and Differential pressure gauge , Temperature gauges , Resistance temperature detector, Thermocouples. Different and details of their principle can be available in a book therefore need not to be discussed here. I request reader to scan through the leaflet of the manufacturer and understand the applicability. I like to mention please be careful about the connection ( i.e thread available in the instrument and process). Most of the time it is observed mismatch between the two and land into problem during installation which may require one more piece to match both.

Specification for Pressure Gauge and Differential Pressure Gauges

Type :Bourdon /Bellow /Diaphragm

Sensing Element material : AISI 316 SS

Movement Material : AISI 304 SS

Case Material : Die cast Aluminium, stove enameled ,black finish

Threaded bezel Ring ,clear glass cover as per

NEMA 4x

Dial Size : Generally 150 mm, other sizes are 100mm,

250 mm as specified.

Scale Size : Black lettering on white background in 270 Degree arc.

Range Selection : Normal process pressure 70 per cent of Range.

Over range Protection :12% of maximum range by internal stop. External

Stop at Zero.

Adjustment : External micrometer screw for zero adjustment .

Internal micrometer screw for range adjustment

Element connection Brazing for range below 40 kg/ cm2

Argon welding for range above 40kg/cm2.

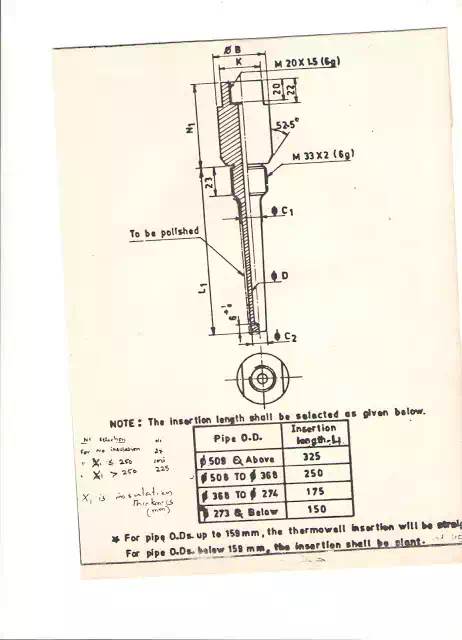

Process Connection M20x1.5 (M) { bottom or back}

Performance Accuracy :+/- 1.0 % or less of span. 80deg ambient

Safety feature Blow out disc at the back.

Applicable standard IS:3624-1966

Specification for local Temperature gauges (Capillary)

Type Mercury filled

Sensing Element material Bourdon- AISI 316 ss/ chrome moly

Bulb and capillary material ,dia AISI 316 ss /12 mm

Capillary armouring Solid drawn 316SS with SS armour

Movement material 304 SS

Thermowell connection M33x2

Case material Die cast aluminium , black finished.

Dial Size 150 mm

Scale Black lettering with white back ground

Mounting Surface

Over range protection 125% FSD

Instrument Connection Bottom /M20X1.5

Accuracy +/- 1% of full scale ,Zero adjustment

Enclosure class IP 55

Capillary Length 5 M

Accessories Thermowell ( weldable or screwed as per

ASMEPTC code.

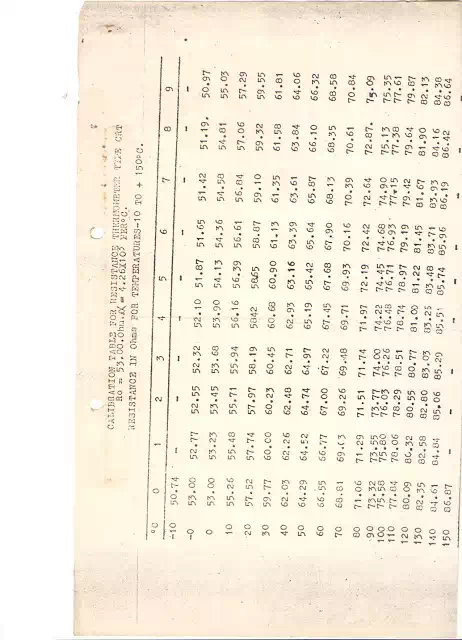

Specification for Resistance Temperature Detector

Platinum / Copper

Type : Platinum / Copper.

Resistance 100 ohm at 0 deg C / 53 ohm at 0 deg C

Base wound on ceramic

Wiring 3 wire system

Protecting Tube 8mm/316 Ss seamless , filling MgO ( purity 99.4%)

Head NEMA 4X/IP55, Die cast aluminium, Brass Terminal

Silver plated , cable gland with grommet , Terminal

Head cover with SS chain and suitable gasket

Accessories Connection , flanges , thermowell , conduit etc.

Simplex / Duplex Duplex.

Standard DIN 43760

Response Time 30 secs

Accuracy 0.1 at 0 deg C

Insulation Resistance 10M ohm at 250V Dc at 27deg C and 600deg C

Specification for thermocouples

Type Cr. Al ( popularly known as K-type.)

Wire gauge 16 AWG

Standard ANSI-C96-1- 1975

Protecting Tube 6 mm OD, 316 SS Seamless , MgO filling

Loading Spring loaded.

Head IP 55 , Die –cast aluminium , Brass Silver plated

Connector , cable gland, head cover with SS

Chain and suitable gasket.

Accessories Thermowell , flanges ,fittings etc as per requirement

Type of grounding Ungrounded/grounded as per requirement

Response time within six seconds

Accuracy Standard ISA

All the specification given above is typical can be changed according to process requirement. RTD generally used are platinum RTD or copper RTD. In BHEL sets copper RTD are used mostly in generator stator and stator water circuit and blance all the places it is platinum RTD.