The Make-up Valve in the Power Plant Steam to Water Cycle

This water is known as condensate, and after leaving the boiler feed pump at high pressure, itís known as boiler feed water. Today weíll introduce a special valve into the system, whose job it is to perform the important function of compensating for lost water. Itís known as the make-up valve.

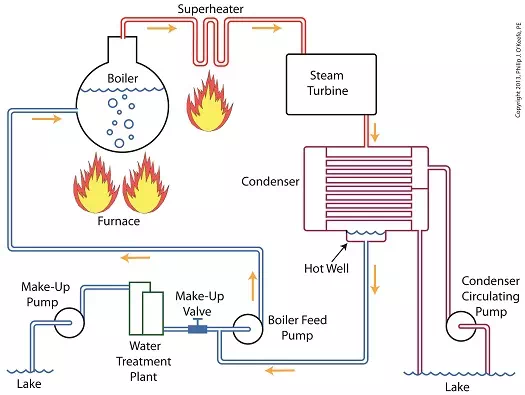

The illustration shows the flow of steam and water within the cycle. Tracing the path of orange arrows will reveal it as a closed system.

Under ideal operating conditions recycled condensate from the condenser would provide enough water to keep the boiler indefinitely supplied. In reality water and steam leaks are a chronic problem within power plants, even when well maintained. Leaks typically occur due to worn parts on equipment, a condition which is commonly present due to the demanding operating conditions they must endure. First, there is the strain of continuous operation, then there are the high temperatures, typically greater than 1000įF, and high pressures that pipes, valves, pumps, and the boiler itself must endure. Weíre talking about pressure higher than 2000 psi, that is, pounds per square inch. As a result, water levels within the boiler must periodically be replenished.

While tracing the arrows through the diagram, you would have come across the new make-up valve under discussion. Itís located on the pipe leading from the power plantís water treatment system to the boiler feed pump. Itís normally kept closed, except under two circumstances, when the boiler is initially filled at startup, or when water replenishment needs to take place.

Due to water loss and difficult operating conditions, maintenance within the water-to-steam system of a power plant is a never ending task. There are miles of pipe connected to hundreds of pieces of equipment, all of which are distributed through a huge power plant structure. So the reality is that power plants operate with a continuous eye on leakage.

To contend with the leaks, human intervention is often required in the way of a boiler operator. Their job is to manually open the make-up valve to admit a fresh supply of water from the treatment plant to the boiler via the boiler feed pump. Once the systemís water requirements are replenished, the valve is once again closed.