Boiler Feedwater Pump Balancing Line

Due to pressure difference across the pump there is always thrust on the rotor

toward suction side of pump due to fluid. Therefore, there balancing system is

required.

Balancing drum

Balancing drum is cylindrical portion installed on the rotor of the pump

generally at the discharge end side. Small gap in mm is maintained axially

between casing or dummy piston which is stationary part attached with pump

casing.

One side of balancing drum, pressure=discharge pressure while another side of

balancing drum, the pressure =suction pressure (slightly greater than suction

pr. which is maintained by a balancing line connected to suction line of pump.

Therefore, due to pressure difference across balancing drum there is thrust

which will opposite to the thrust created by fluid.

Balancing Disks

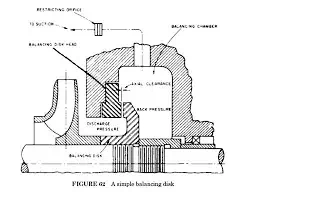

The operation of the simple balancing disk is illustrated in Figure above. The

disk is fixed to and rotates with the shaft. It is separated by a small axial clearance

from the balancing disk head, or balancing sleeve, which is fixed to the

casing. The leakage through this clearance flows into the balancing chamber and

from there either to the pump suction or to the vessel from which the pump

takes its suction. The back of the balancing disk is subject to the balancing

chamber back pressure, whereas the disk face experiences a range of pressures.

These vary from discharge pressure at its smallest diameter to back pressure at

its periphery. The inner and outer disk diameters are chosen so that the

difference between the total force acting on the disk face and that acting on

its back will balance the impeller axial thrust.

If the axial thrust of the impellers should exceed the thrust acting on the

disk during operation, the latter is moved toward the disk head, reducing the

axial clearance between the disk and the disk head. The amount of leakage

through the clearance is reduced so that the friction losses in the leakage

return line are also reduced, lowering the back pressure in the balancing

chamber. This lowering of pressure automatically increases the pressure

difference acting on the disk and moves it away from the disk head, increasing

the clearance. Now the pressure builds up in the balancing chamber, and the

disk is again moved toward the disk head until an equilibrium is reached.

To assure proper balancing in disk operation, the change in back pressure in

the balancing chamber must be of an appreciable magnitude. Thus, with the

balancing disk wide open with respect to the disk head, the back pressure must

be substantially higher than the suction pressure to give a resultant force

that restores the normal disk position. This can be accomplished by introducing

a restricting orifice in the leakage return line that increases back pressure

when leakage past the disk increases beyond normal. The disadvantage of this

arrangement is that the pressure on the seal chamber is variable, a condition

that may be injurious to the life of the seal and therefore should avoided.