Boiler Feed Water, A Special Kind of Condensate

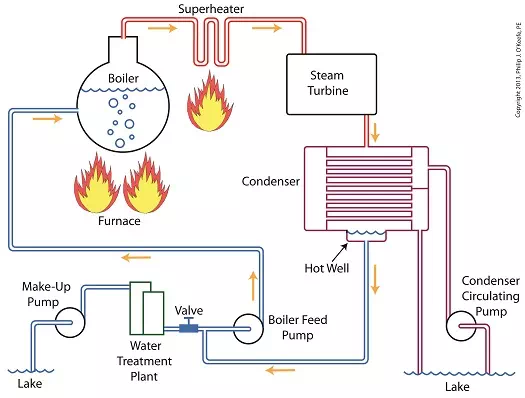

Letís begin by integrating the condenser into the big picture, the complete water-to-steam power plant cycle, to see how it fits in. The illustration shows that both the make-up pump and the condenser circulating water pump draw water from the same supply source, in this case a lake. The circulating water pump continuously draws in water to keep the condenser tubes cool, while the make-up pump draws in water only when necessary, such as when initially filling the boiler or to make up for leaks during operation, leaks which typically occur due to worn operating parts.

In a nutshell, the condenser recycles steam from the turbine exhaust for its reuse within the power plant. The journey begins when condensate drains from the hot well located at the bottom of the condenser, then gets siphoned into the boiler feed pump.

If you recall from a previous article, the boiler feed pump is a powerful pump that delivers water to the boiler at high pressures, typically more than 1,500 pounds per square inch in modern power plants. After its pressure has been raised by the pump, the condensate is known as boiler feed water.

The boiler feed water leaves the boiler feed pump and enters the boiler, where it will once again be transformed into steam, and the water-to-steam cycle starts all over again. That is, boiler feed water is turned to steam, itís superheated to drive the turbine, then condenses back into condensate, and finally itís returned to the boiler again by the boiler feed pump. Trace its journey along this closed loop by following the yellow arrows in the illustration.

While you were following the arrows you may have noticed a new valve in the illustration. Itís on the pipe leading from the water treatment plant to the boiler feed pump. Next time weíll see how this small but important item comes into play in the operation of our basic power plant steam and water cycle.