Injection Blow Molding Machine

Injection Blow Molding MachineBlow Molding Machine

blow molding machine is a one type fabrication of plastics , it is Used to manufacture of Hollow object by inflating heated plastic tube to fill a mold or die and form for require shape. The thermoplastic is a blow moulding materials, Which is contain the form of small pellets or granules. This is melted first and formed into hollow tube, It is called Parison. In this Parison is clamped between the two mold halves and inflated by high pressurized air (350 – 700 Kpa) into inside the mold cavity. After fill of parison to the mold cavity, the object is cooled together and ejected from mold halves.

The following materials used for plastic blow molding:They are following

· High density polyethylene

· Medium & Low density polyethylene

· polyethylene Terephthalate

· polypropylene

· Polyvinyl Chloride

· Thermoplastic Elastomers

· Polystyrene

· Poly carbonate

· Fluoropolymers

· Polyimide/Nylon

This blow moulding machine manufacturers of Hollow shape, Thin-walled shape such as

· Bottles

· Tubes

· Water Tanks

· Containers

· Plastic Drums

· Injection Type

· Extrusion type

· Stretch type

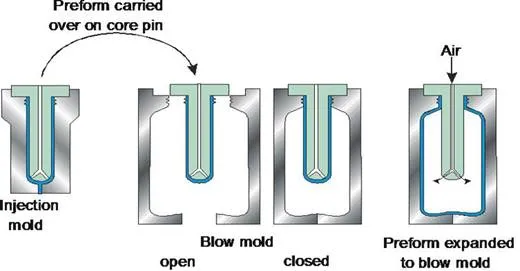

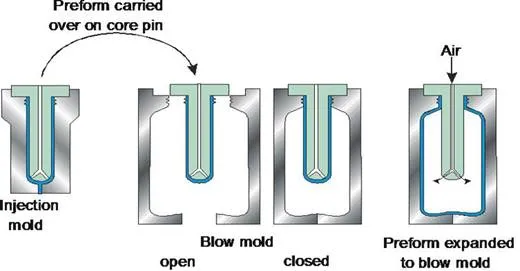

The injection blow molding is used to mass production of hollow plastic product. In this proces consider for three stage (i) Injection (ii) Blowing (iii) Ejection. The injection unit having the melted plastic injected to the hollow mold through Nozzle that also consist of blowing rod. The injected metal is called ” Parison (Preform) “. The blowing rod internal shape of parison and external shape of mold form. Thus Parison is thick tube of inside in the mold part.

Injection Blow Molding Machine

Injection Blow Molding Machine

Close the Mold: The Injected unit is removed and parison added to mold open and blowing rod with parison moved and clamped into the hollow. Now close the mold part.

High Pressurized Air Applied to Mold: When the closed mold, the blowing rod opened and to allow high pressurized air into the parison. The Parison is forced by air toward the wall of below mold. So Parison come to require shape of mold cavity.

Eject the mold Part:The blowing rod moved in ejection position for after cooling process completed. Now mold part is Ejected.

Extrusion Blow Moulding diagram

Extrusion Blow Moulding diagram

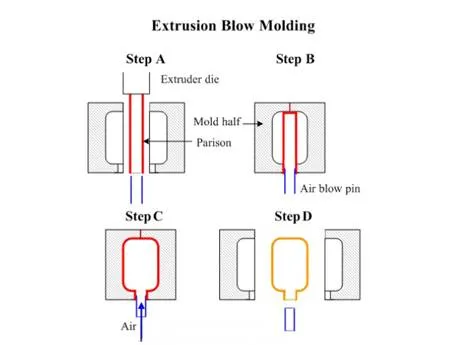

In this method the parison is extruded downward between two open blow mold. The parison reached with proper length and mold closed together, catched and holding the neck-end of open & pinching the bottom side of mould. The below pin is inserted into the neck end of hot parison when the form threaded open & to inflate the parison inside the mold inflate through blow pin to take up shape of mold. To take sufficient amount of time in cooling and mold opened to eject the object.

Stretch blow molding is mainly used to mold of hollow objects such as Soda Bottle and short shape parts. In this process , the plastic metal is first molded into “preform” by using normal injection molding. Then preform is pre-heated (Infrared heater) before inject the two halve of mold. When the preform is inflated to allow high pressured air while being stretched with blowing rod. The Blowing rod is pushed into the preform before stretch. Now, The Preform is transfer to blow mold. Then after curing, the molded part ejected from mold.

· small capital investment in eqipment

· Suitable for small Production

· Tool cost is Low

· Low Production Time Required

· Complex Shape can be manufactured

· The Hollow and wall thickness parts controlled for very difficultly.