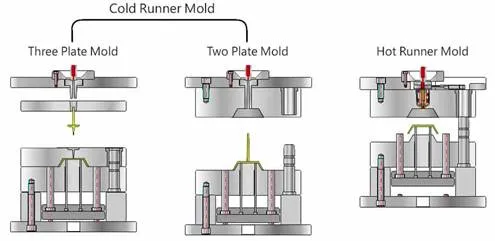

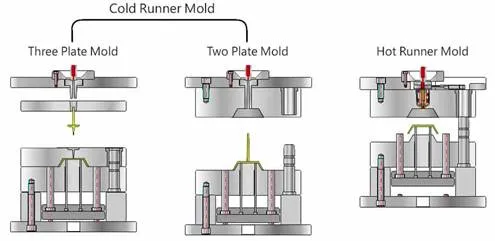

2 plates mold,3 plates mold and hot runner mold

There are many classification for plastic injection molds.

According to the basic injection mold gating system, it can be divided into three types:

1. Two-plate mold;

2. Three-plate mold;

3. Hot runner mold, also called runner-less mold.

Other plastic molds, such as side core pulling mechanism, core-unscrewing de-molding mechanism, are evolved from these three types of molds.

Two-plate mold

Two-plate mold or single parting surface mold is the simplest and most widely used mold in injection molding.

The 2 plates mold are divided into two parts: the moving half and the fixed half by P/L.

Core side is in the moving mold half and the cavity side is in the fixed mold half.

The runner is in the fixed mold, and the main runner is arranged on the parting surface.

After molding, the injection molded product and runner remain in the moving mold half, the product and the injection system are ejected off from the same parting surface.

And the movable mold half is equipped with ejection systems to push the products away after opening the mold.

Other moulds are the development of two-plate moulds.

3 plates mold is also called double parting surface mold.

The mold is divided into three parts, a runner stripper plate is added between the top clamping plate and cavity plate.

This structure is suitable for products are not allowed to have gate marks along sidewall,or item with a large projection area and needing multi point gates.

This kind of mold adopts pin point gate.

This kind of mold has a more complicated structure and needs an additional distance parting mechanism.

The three-plate mold is divided into normal three-plate molds and the simplified three-plate mold.

Simplified three-plate mold doesn’t have four guide pins between moving and fixed half.

Hot runner mold is also called runner-less mold, including insulated hot runner mold and heated runners mold.

The plastic in the gating system is always in a molten state, so there will be no gating system material such as two-plate mold and three-plate mold in the process.

The hot runner mold integrate the advantages of simple action of the two plate mold and the melt of the three plate mold entering from any point in the cavity.

In addition, the hot runner mold has no loss of pressure, temperature and time in the runner, so it not only improves the injection molding quality, but also shortens the molding cycle, which is a major innovation in the gating system technology of the injection mold.

In Japan, the United States, Germany and other countries with highly developed injection molding technology , the hot runner injection molds are very popular, accounting for about 65%.

Hot runner system has been widely used, mainly because it has incomparable advantages over traditional 2-plate and 3-plate molds:

1. Shorten the cycle time. Because there is no limitation of the cooling time of the runner system, the part can be ejected son after solidification. Many thin-walled parts produced with hot runner molds can be molded in less than 5 seconds;

2. Plastic Raw Materials Saving. Because there is no runner material in the hot runner mold, there is no production cost. This is especially significant for reducing the cost of raw materials. The major hot runner manufacturers in the world have developed rapidly for the plastic raw materials are expensive in the world now. Because hot runner technology is an effective way to reduce the cost of materials.

3. Reduce the failed parts and improve the product quality. For the hot runner mold production, the temperature of the plastic melt is accurately controlled in the runner system. Plastic can flow into each mold cavity in a more uniform state, thus producing parts with consistent quality. In addition, hot runner molding have beautiful gate relics , low residual stress , and smaller part deformation. Therefore, many high-quality products on the market are produced by hot runner molds.

4. Eliminate the subsequent operation . The finished product is obtained after the finished product is molded by a hot runner mold, and the subsequent operations such as trimming a gate and regrinding cold runner are not required. It is good to production automation.

Top

The structures of the two-plate mold and the three-plate mold are shown . Their differences are as follows.

· Different structures:

(1) runner ejection plate;

(2) guide pins and guide sleeves on the runner ejection plate;

(3) Fixed distance parting mechanism . The mechanism that guarantees the mold opening sequence and mold opening distance is called fixed distance parting mechanism.

· Different mold gate systems

(1) Three-plate injection mold can be gated from any point in the cavity, and pin point gates are often used.

(2) The two-plate mold is mostly fed from the outer side of the cavity, and side gates are often used. When the product is large or there is a large hole in the middle of the product, it can also be fed from the inner side. In addition, the submerged gate can also be cut on the cavity.

(3) During the three-plate mold production, the runner system and the product will be automatically cut off and separated, which is convenient for realizing automatic production; However, the runner system and the product of the two-plate mold production usually needs to be removed manually .

· The different parting surface

There is only one PL during the 2-plate mold injection molding production . The product and the injection system material are taken out from the same parting surface.

However, during the three-plate mold injection molding production , there are three surfaces to be opened, and the product and the injection system are taken out from different parting surfaces.

· The different manufacturing cost

the three-plate mold is more expensive, and the manufacturing time is longer.

· The different action principle

The three-plate mold can automatically cut off the gate during the production process. The mold can be fully automated and the product quality is good.