Mould cores and cavities

Within our mold steels range your will find a solution suitable for all kind of plastic parts that vary in material, size, complexity and application. Our steels can be used for all plastic moulding processes such as injection, compression, blow and rubber moulding.

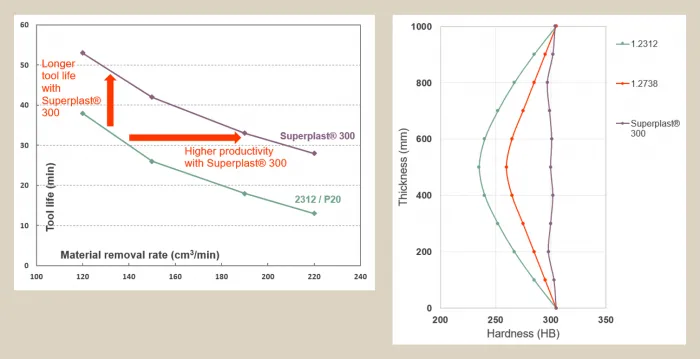

Producing high quality injection moulds and plastic parts in a cost effective way is a daily challenge for moldmakers, moulders and OEM. Superplast® is a complete range of premium mould steels dedicated to the plastic injection moulding business. Superplast grades are delivered prehardened from 300 Brinell to 400 Brinell to produce mould cores, cavities and holders.

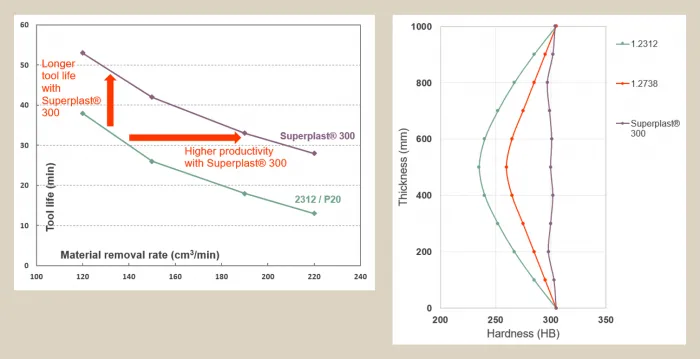

The concept of Superplast® steels is based on a lean analysis for a better machining combined to boron metallurgy for an extra high through homogeneity. Thanks to this, Superplast steels provide reliable machining, consistent surface finish and texturing, improved thermal conductivity, easy weld repair and high mechanical strength for a large dimensional range (up to 1300mm thickness).

Quality and reliability

Superplast steels are covered by a guarantee covering metallurgical quality and reliability in your daily use.

INDUSTEEL TRADEMARKS | DIN | W.Nr | AISI | Hardness HB | Hardness HRC |

2311 | 40CrMnMo 7 | 1,2311 | P20 | 280-325 | 29-34 |

2312 | 40 CrMnMoS 8.6 |

| ≈ P20+S | 300 |

|

2714 | 55 NiCrMoV 7 | 1,2714 |

| 360-400 | 39-43 |

2738 (P20) | 40 CrMnNiMo 8-6-4 | 1.2738 | P20 + Ni | 280-325 | 29-34 |

W 1.2767 |

|

| ≈6F7 |

|

|

Superplast® 300 |

| 1.2738mod | P20mod | 290-330 | 30-35 |

Superplast® 350 |

|

|

| 330-360 | 35-39 |

Superplast® 400 |

|

|

| 350-380 | 38-42 |

Superplast® Premium | proprietary |

|

| 290-380 | 30-42 |