ANIONIC POLYMERIZATION

Anionic polymerization is a form of chain-growth polymerization that encompasses the polymerization of vinyl monomers with strong electronegative groups. This type of polymerization is often employed to produce synthetic polydiene rubbers, solution styrene-butadiene rubbers (SBR), and thermoplastic styrenic elastomers.1,2

All monomers with (strong) electronegative substituents polymerize readily in the presence of carbanions. Some electron-withdrawing substituents that stabilize the negative charge through charge delocalization, and hence permit anionic polymerization include -CN, -COOR, -C6H5, and -CH=CH2, to name only a few. Therefore, monomers such as styrenes, dienes, acrylates and methacrylates, aldehydes, epoxides, acrylonitriles and cyanoacrylates readily undergo anionic polymerization reactions.

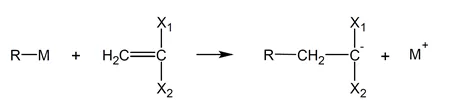

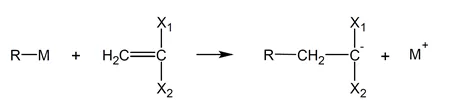

The electron donors (or initiators) are either electron transfer agents or strong anions. The transfer of an electron from a donor molecule to the vinyl monomer leads to the formation of an anion radical, the so-called carbanion:

Typical electron donors (Lewis bases or nucleophiles) are alkali metals, such as lithium or sodium. Other strong nucleophilic initiators include covalent or ionic metal amides, alkoxides, hydroxides, amines, phosphines, cyanides, and organometallic compounds such as alkyl lithium compounds and Grignard reagents.1-3 The initiation proceeds by addition of a neutral (B:) or negative (B:-) nucleophile to the monomer.

The kinetics of an anionic polymerization consists of initiation, polymerization and termination. For example, the initiation and polymerization of styrene with potassium amide proceeds as follows:4

KNH2 ⇔ K+ + NH2-

NH2- + M → NH2M-

NH2Mn- + M → NH2Mn+1-

NH2Mn- + NH3 → NH2MnH + NH2-

The "Gegen" ion, K+, can be omitted from the scheme above, because it is dissolved ("free") in a media of comparatively high dielectric constant.4,5

In carefully controlled systems (pure reactants and inert solvents), an anionic polymerization does not undergo termination reactions. Hence, the chains will remain active indefinitely unless there is deliberate termination or chain transfer. This has two important consequences:

This type of polymerization is called living polymerization.

Anionic polymerization can also be used to functionalize polymers, for example by reacting the active chain ends with electrophilic reagents which yields a wide variety of telechelic polymers. The electrophilic reagents (epoxide, aziridine, CO2, etc.) are usually added at the end of the polymerization. End-groups that have been produced in this way include -OH, -SH, -NH2, COCH3, and -COOH, to name only a few.7

An alternative approach for functionalizing polymers is to begin the polymerization with a functional anionic initiator (see example above).