BALL MILLING OR MECHANO-CHEMICAL DESTRUCTION (MCD)

This technology is a mechanochemical application that combines mechanical impact with chemical reagents to create a reduction reaction for chlorinated substrates such as PCB or pesticides. The objective is to achieve reductive dehalogenation of the POPs waste. The waste contaminated with POPs is placed into the ball mill device with an alkali metal compound that acts as a hydrogen donor, and is vibrated vigorously to permit agitation of the steel balls, reagent, and waste mix. The process is conducted at room temperature, in closed vessels, and no heating is required. There is no process gas to manage, avoiding the release of hazardous organic compounds.

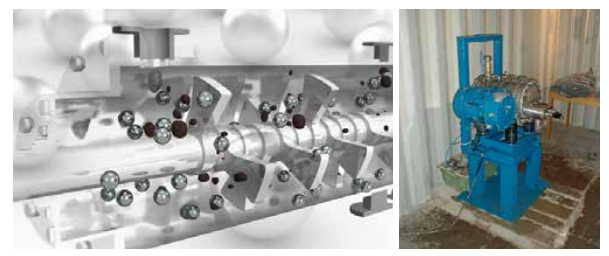

Figure 36. Illustration of the interior of a rotating ball mill.

Chlorine in the POPs waste is converted to inorganic compounds called CaCl2 or Ca(ClOH). The reagents can include calcium oxide (CaO), magnesium (Mg), sodium, and other metals, including their oxides. The contaminated material is placed in the ball mill, which is essentially a metal vessel that can operate like batch reactor, or even as continuous reactors with the reagent and ball bearings. In addition to PCB and pesticides, it has also been successfully applied to dioxin-contaminated soils. Three commercial applications are well-developed and rely on the same principles: Tribochem’s Dehalogenation by Mechanochemical Reaction (DMCR), EDL’s Mechano-Chemical Destruction (MCD), and Radicalplanet (Research Institute Pty Ltd). Lab-based experiments using ball milling have also proven effective at destroying hexabromocyclododecane and polybrominated diphenyl ethers.

One technology vendor (EDL Europe) describes their Mechano-Chemical Destruction (MCD) process: “…the ball-to-ball and ball-to-surface collision points are the major regions of fracture and chemical reaction initiation. The reactions induced at the fracture point include radical formation and electron transfer resulting in the destruction of chemical bonds. EDL exploits these chemical phenomena to destroy even the most persistent contaminants which pose a threat to human and environmental health.”

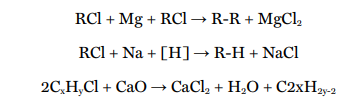

EDL uses a version of this technology they have patented known as Mechano-Chemical Destruction (MCD) to remediate soils and pesticides. In their version of the technology, an additional central spinning shaft fit ted with rotors is included with the main reactor vessel. As the shaft spins it agitates the ball bearings at high speed, leading to a much higher rate of ball-to-ball and ball-to-surface impacts. The chemistry is very complex and relies on radical transformations involving metal-organic radical species. Simplified versions of the reactions are shown below.

More recently, EDL Europe conducted a joint UNDP/GEF-funded trial remediation of a former US air base in Bien Hoa, Vietnam, treating 150 tons of soil contaminated with dioxin and dioxin-like PCB. The technology achieved high destruction efficiency for the dioxin, reducing its levels in soil down to as low as 1,000 ppt (1 ppb). A number of other technologies were trialled at the Bien Hoa site to assess suitability for the full-scale remediation of the site. MCD has been shortlisted in the selection criteria and cost estimates by comparison with incineration for the dioxin waste were around US $60 million less expensive for the MCD process, which does not generate UPOPs. They have also completed projects treating pesticides, PCB, and dioxins for the US military in Alaska and California, and for the Japanese government and multiple private projects. The first major site remediation was in Mapua, New Zealand, which was heavily contaminated with lindane, DDT, dieldrin, and aldrin. The site is now converted to mixed residential and recreational use.

Ball milling has also been trialled favorably for its ability to debrominate plastics contaminated with brominated flame retardants which would allow the polymers to be recycled safely .